Salgenx LLC • Design • Develop • Analysis • Grid Scale Flow Battery

TEL: 1-608-238-6001 (Chicago Time Zone )

Email: greg@salgenx.com

3 MWh Grid Scale Saltwater Flow Battery that is Self Healing More Info

$500,000 Technology Development Kit (TDK) Register your own IP with our package. Finish your own cathode then own your IP, then manufacture. Buy sales leads, license or buy Salgenx name for your own production. More Info

|

|

Technology Development Kit (TDK) $500,000 Salgenx has built the saltwater battery platform and the hard parts of the electrochemical architecture. The remaining variable is cathode selection and final cathode-electrolyzer tuning, which depends on the buyer’s target chemistry, sourcing, and manufacturing strategy. The Salgenx Technology Development Kit lets a buyer start from a validated foundation, finish the cathode to fit their IP strategy, and commercialize under their own brand—or optionally under the Salgenx name—without licensing or buying the entire company. |

|

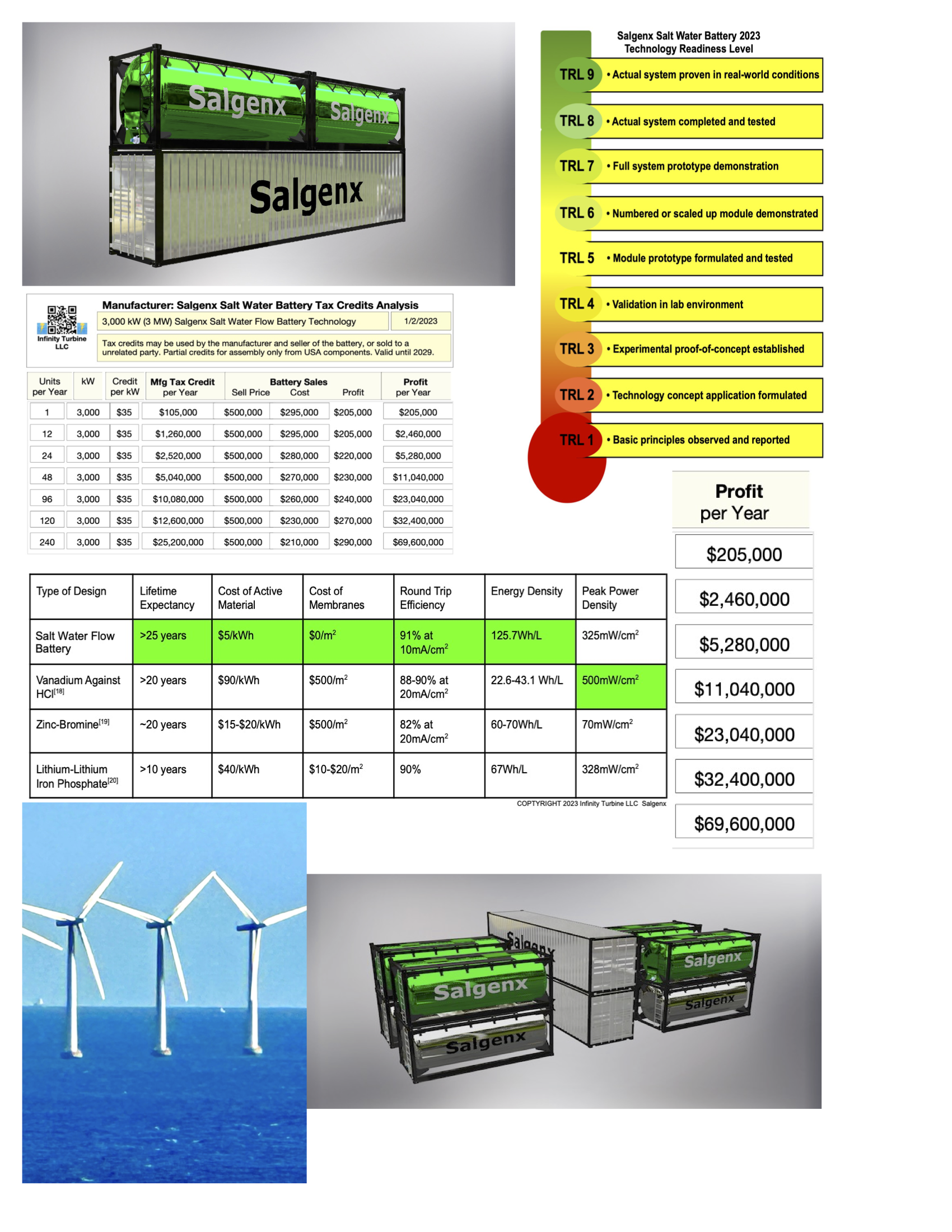

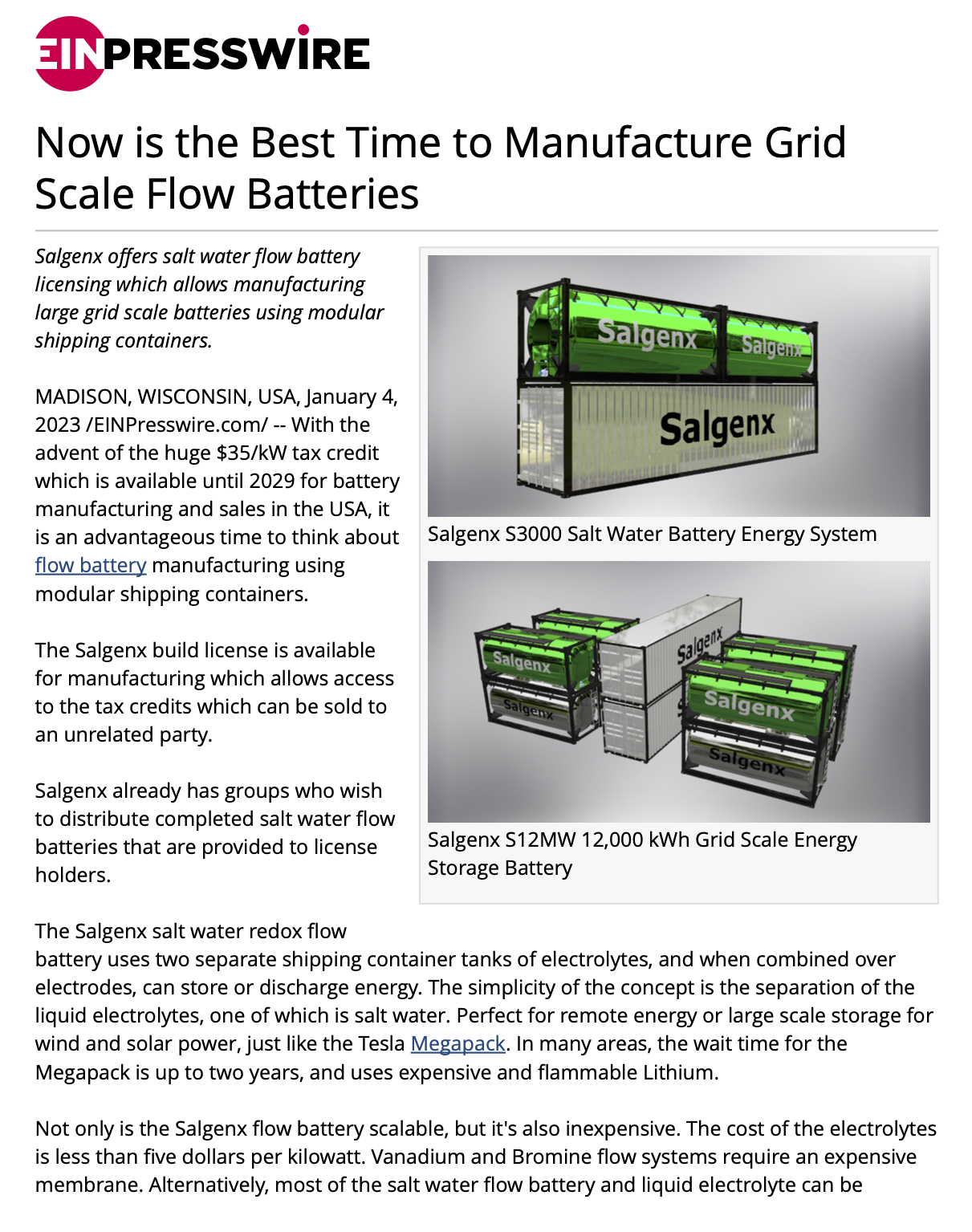

We design the Technology. You Build and Commercialize the Product. The Salgenx sodium flow battery is unique, in that it can not only store electricity, but perform simultaneous processing functions.• Store grid-scale power • Store thermal energy (including cogeneration)• Perform selectable revenue processes according to highest revenue on-demand (AI tunable logic may select from charging to thermal storage, and more)• Build for less than $300,000 for a 3-6 MWh System• Use pre-made (new or used) shipping containers for the battery saltwater and electrolyte storage• The only fabrication are the flow pumps and electrolyzers which you may purchase pre-made to assemble at your location• Low cost Zinc based electrode materialThe 6 hour flow battery charge rate can be discharged at any time and the stored energy can be held almost indefinitely.$35/kWh USA Battery Tax Credit (paid directly from IRS or may be sold to unreleated party) amounts to $150,000 per 3,000 kWh battery. That is about half of the production cost.The Company That Controls Battery Technology Controls the World |

|

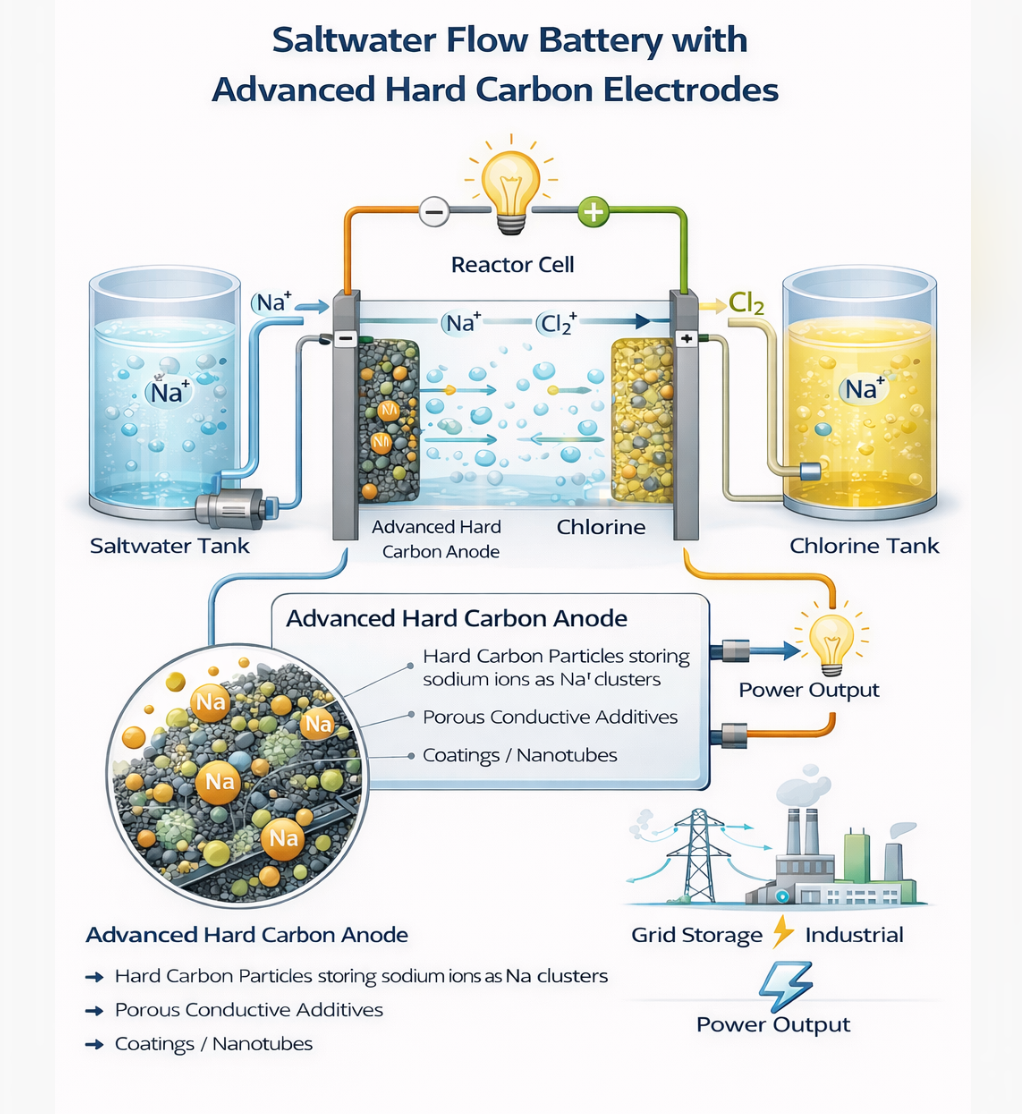

Breakthrough Findings from the Hard Carbon Kinetics Study Recent work using the diluted electrode method reveals that sodium insertion into hard carbon can exceed lithium in kinetic performance, with diffusion coefficients approaching 10 to the minus 10 square centimeters per second and lower activation energy. These findings provide a direct pathway to redesigning saltwater flow battery electrodes and enabling next generation ferro fluid sodium ion storage architectures. |

|

|

The Opportunity to Build and Sell a Grid-Scale Sodium Flow Battery and Make $600,000 Income Per Day with a Production of only 2 Batteries Per Day Consult with Salgenx and manufacture the batteries to ship anywhere in the world. You own the IP you develop.We can provide you with customers through our website and network of pre-existing customers.While we continue to develop and enhance the saltwater battery features together, you deploy to the market and take profits. |

|

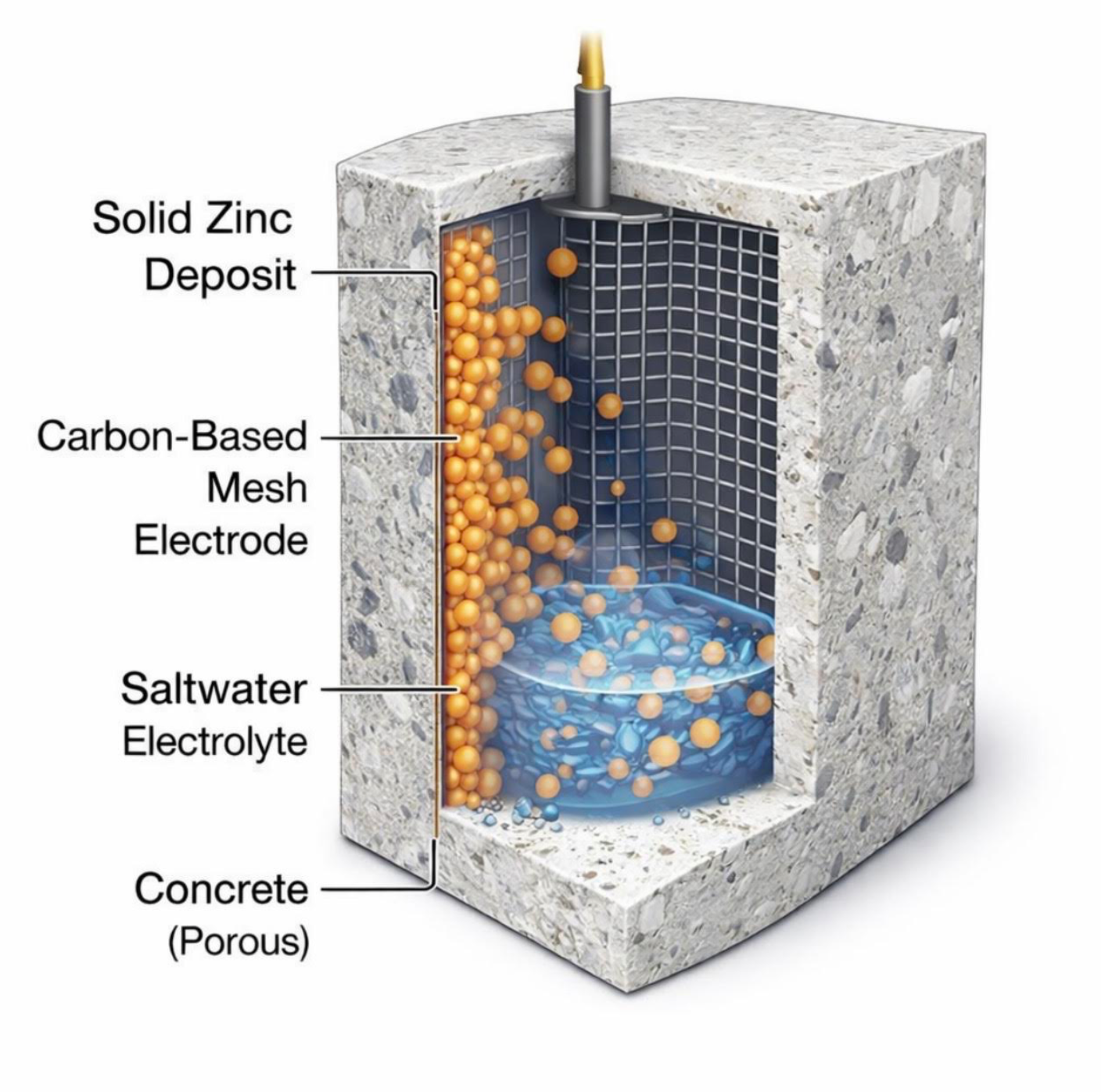

Concrete Battery Concrete is no longer just a structural material. When engineered with controlled porosity and embedded conductive networks, it can function as an electrochemical medium that stores energy, stabilizes ion transport, and suppresses dendrite growth. This article explains how concrete can be integrated with membrane free saltwater flow batteries, how ions move through cement structures, and how performance compares to conventional flow battery designs. |

|

| CONTACT TEL: +1 608-238-6001 (Chicago Time Zone) Email: greg@salgenx.com | AMP | PDF | Salgenx is a division of Infinity Turbine LLC |