Saltwater Battery Technology which offer an Alternative to Lithium Batteries

Manufacturing Opportunity:We design the technology so you can commercialize and finalize development from our research to build your own IP portfolio to manufacturing.

|

Saltwater Battery Technology which offer an Alternative to Lithium Batteries Manufacturing Opportunity:We design the technology so you can commercialize and finalize development from our research to build your own IP portfolio to manufacturing. |

|

|

Fastest Path to a 3 MWh Grid-Scale Saltwater Flow Battery: Zinc-Chlorine vs NTP-Based Architectures Which saltwater flow battery chemistry reaches grid-scale commercialization first? This article compares zinc metal and NTP-based chlorine flow batteries across cost, efficiency, manufacturing complexity, and bankability to determine the fastest and most cost-effective path to a 3 MWh system.IntroductionGrid-scale energy storage increasingly demands systems that are safe, low-cost, scalable, and free from constrained materials. Saltwater flow batteries, particularly chlorine-based systems, have re-emerged as a compelling alternative to lithium-ion due to their use of abundant materials, non-flammable electrolytes, and long cycle life.Recent research has demonstrated a membrane-free chlorine flow battery architecture with exceptionally low projected material cost. Within this platform, two negative electrode strategies emerge as candidates for commercialization:1. Zinc metal negative enabled by a ZnCl2 additive2. NaTi2(PO4)3 (NTP) intercalation negative without zinc additiveThis article evaluates both approaches for a 3,000 kWh grid-scale containerized system and determines which offers the fastest, lowest-risk, and most cost-effective path to market.System Architecture OverviewBoth battery variants share a common core architecture:• Aqueous NaCl electrolyte• Chlorine redox at the positive electrode• Closed-loop chlorine handling using an immiscible organic carrier• Membrane-free stack design• Modular stacks arranged into a roughly 900 V DC busThe primary difference lies in the negative electrode chemistry and its implications for voltage, efficiency, manufacturing, and cost.Option A: Zinc-Chlorine Flow Battery with ZnCl2 AdditiveElectrochemistry• Positive: Cl2 / Cl minus• Negative: Zn2 plus / Zn metal• Nominal cell voltage: approximately 1.9 VAdding ZnCl2 to the electrolyte enables reversible zinc plating and stripping, replacing the need for a solid-state intercalation cathode.Manufacturing and Commercial Advantages• Zinc metal is a commodity material available as sheet, foil, or plated substrates (it is also available at Home Depot).• Electrode fabrication is simple and scalable• No high-temperature ceramic synthesis or vapor deposition steps• Aligns with historical zinc-halogen battery manufacturing experienceThe zinc electrode can be designed as a serviceable component, enabling predictable maintenance rather than end-of-life replacement.Risks• Zinc dendrite formation must be controlled through current density, flow design, and electrolyte management• Coulombic efficiency must be validated at scaleOption B: Chlorine Flow Battery with NTP CathodeElectrochemistry• Positive: Cl2 / Cl minus• Negative: NaTi2(PO4)3 (NTP)• Nominal cell voltage: approximately 1.8 VNTP is a NASICON-type insertion material offering good rate capability and stable cycling.Manufacturing and Commercial Challenges• NTP synthesis requires high-temperature calcination• Conductive carbon coating is necessary, typically involving additional thermal processing or vapor deposition• Powder processing and electrode fabrication add complexity and capital costWhile technically elegant, NTP introduces a more complex supply chain and slower ramp to volume production.Costed BOM Comparison for a 3 MWh ContainerUsing the Nature Communications estimate of approximately $5 per kilowatt-hour as a floor for active materials, and legacy zinc-chlorine plant data as a balance-of-plant sanity check, the following system-level costs emerge:• Zinc-Chlorine system total installed cost: approximately xxxxx dollars• NTP-based system total installed cost: approximately xxxxx dollarsThis corresponds to:• Zinc system: approximately xx dollars per kWh installed• NTP system: approximately xxx dollars per kWh installedIn both cases, balance-of-plant, power electronics, and safety systems dominate total cost, not the electrochemistry itself.Efficiency and Cost-Per-Delivered-kWhEfficiency must be evaluated alongside capital cost to assess true economic performance.• NTP-based systems have demonstrated laboratory-scale energy efficiency exceeding 90 percent• Zinc-based systems typically operate in the 70 to 75 percent range when system parasitics are includedWhen adjusted for efficiency:• Zinc system effective cost per delivered kWh: approximately xx to xx dollars• NTP system effective cost per delivered kWh: approximately xx to xxx dollarsThis indicates that while NTP offers higher efficiency, the zinc system compensates with lower upfront cost and faster manufacturability.Fastest Path to Market AssessmentFrom a commercialization standpoint, the decisive factors are manufacturability, supply chain simplicity, and execution risk.• Zinc metal electrodes eliminate the need for specialty ceramic powders and carbon coating processes• Anodes are already mass-produced industrial components• The zinc system supports a service-based maintenance model familiar to utilitiesThe NTP system, while attractive for future optimization, introduces additional process steps that slow time to first deployment.Commercial VerdictFor a first-generation, grid-scale saltwater flow battery:• The zinc-chlorine system with ZnCl2 additive is the fastest to market• It offers the lowest installed cost• It presents the least manufacturing risk• It enables early revenue and field validationThe NTP-based system is best positioned as a second-generation or premium offering once manufacturing scale and customer confidence are established.ConclusionSaltwater flow batteries based on chlorine chemistry present a credible, scalable alternative to lithium-ion for long-duration grid storage. Between the two leading negative electrode options, zinc metal offers the most direct path to commercialization for a 3 MWh containerized system. Its simplicity, cost advantage, and alignment with existing industrial practices outweigh the efficiency advantage of NTP in early deployments.A dual-track strategy is recommended: deploy zinc-based systems first to capture market share and operational data, while continuing development of NTP-based systems for future high-efficiency products.References1. Hou et al. High Energy and Low Cost Membrane Free Chlorine Flow Battery. Nature Communications, 2022.2. Detroit Edison and Energy Development Associates. Zinc Chlorine Battery Utility Study and Cost Analysis, 1976 to 1977.3. Bard and Faulkner. Electrochemical Methods Fundamentals and Applications. Wiley.4. U.S. Department of Energy. Grid Energy Storage Technology and Cost Characterization Reports. |

Saltwater battery technology and unlimited manufacturing is now available through licensing |

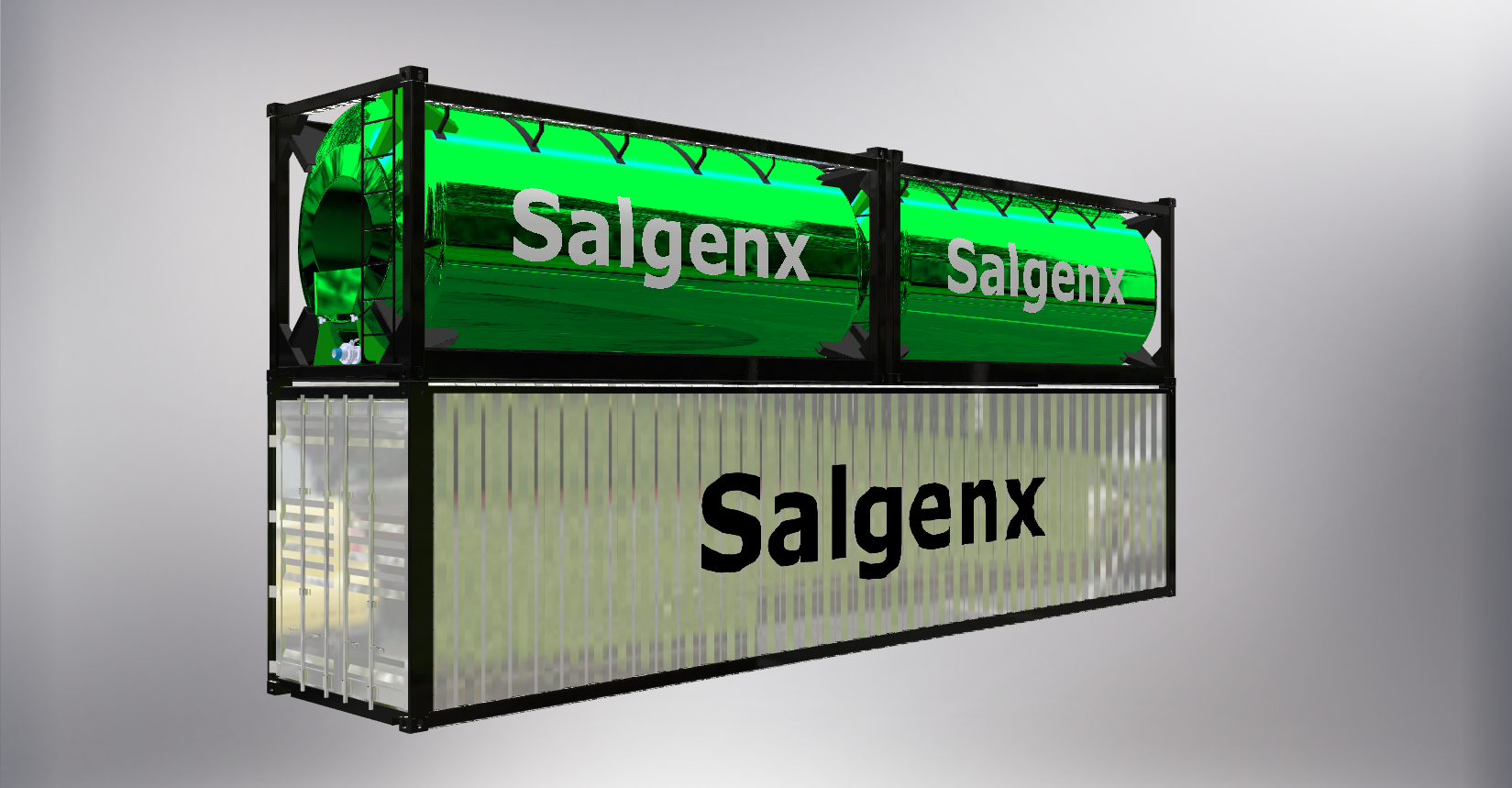

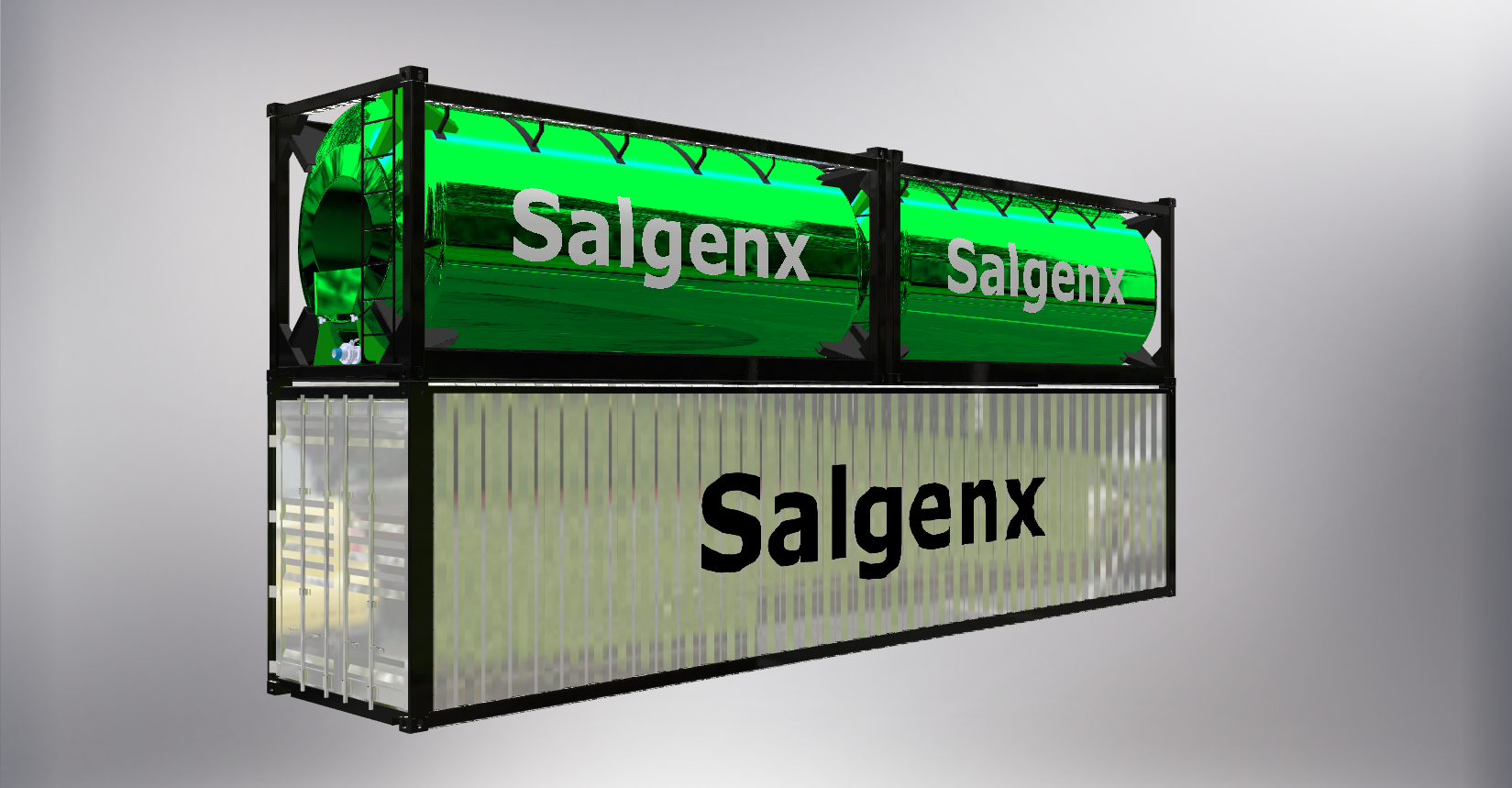

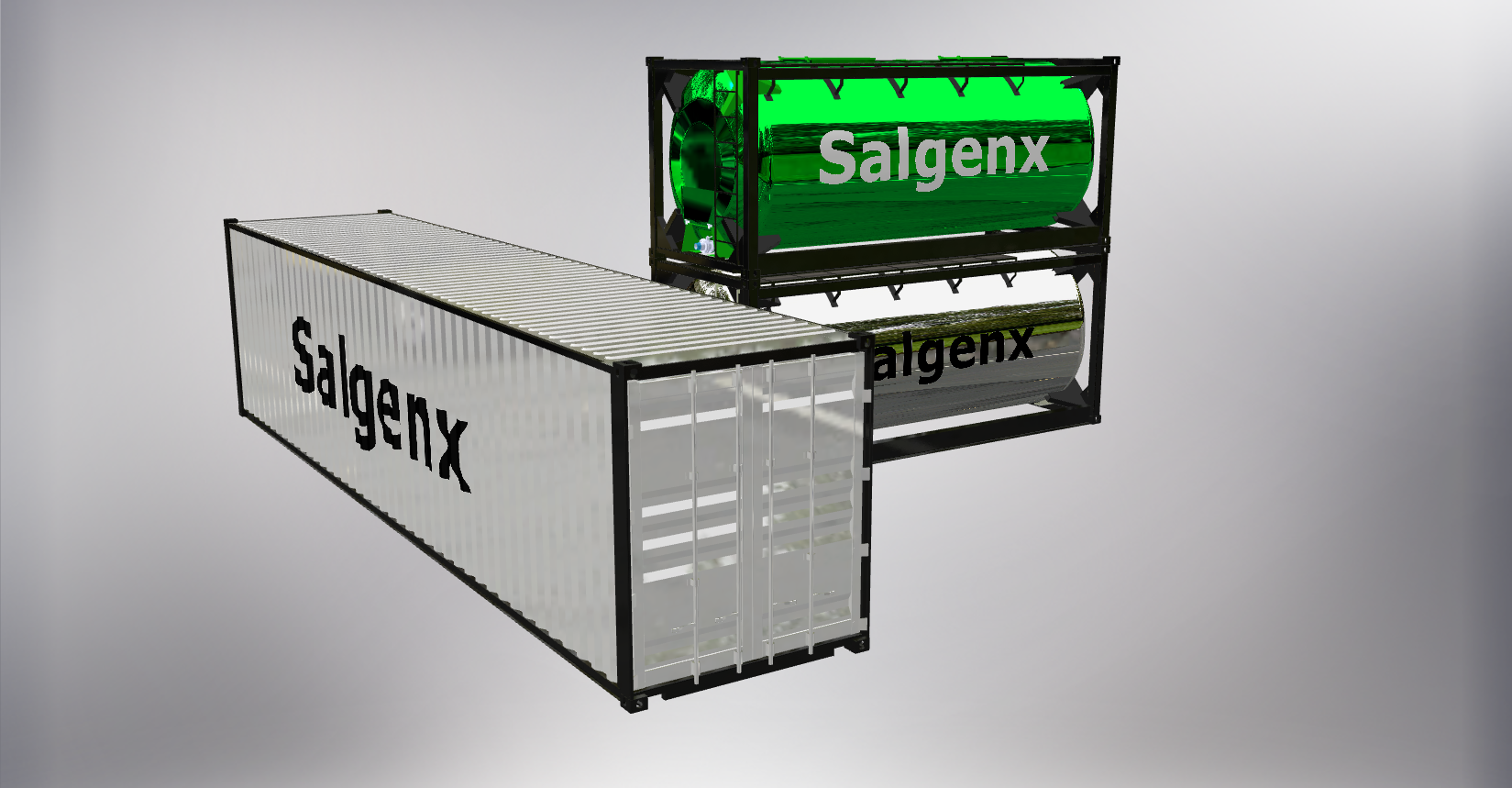

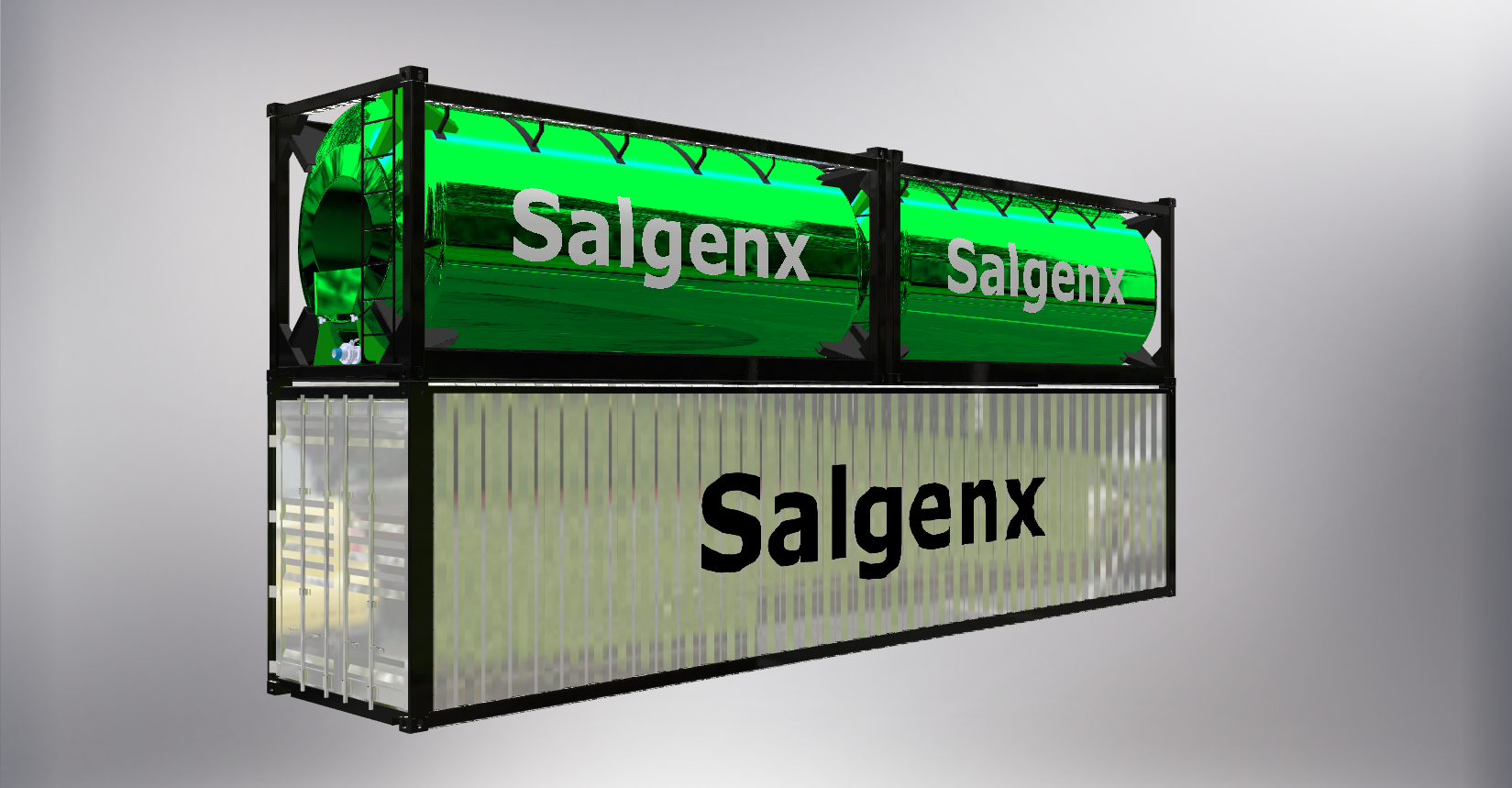

We design the technology and you build the batteries and you retain the IP We are pleased to announce that the saltwater battery technology is now available for you to commercialize and develop. This innovative system features two electrolyte tanks, with one specifically designed for saltwater (brine RO effluent, salars, seawater, and more). Note: for the saltwater, you technically do not need a input tank, for example the process could use the Reverse Osmosis effluent as a direct input.Notably, this technology operates without the need for a membrane.Salgenx offers consulting and you can leverage our expert guidance, you have the opportunity to pioneer the commercial deployment of this groundbreaking technology. Our team specializes in saltwater flow batteries and will collaborate closely with your own team to optimize your core offerings according to the specific needs of your customers.

|

|

Unboxing Factory Assembly Line Salgenx can leverage Tesla’s unboxing factory line methodology to streamline the production of its saltwater battery technology for your commercialization and manufacturing. By adopting an automated, modular assembly approach, Salgenx can significantly reduce manufacturing costs and increase scalability, ensuring high-volume production with minimal labor. The unboxing process enables the battery components to be delivered in a sequence that eliminates excess handling, enhancing efficiency and precision in assembly. This method aligns with Salgenx’s commitment to sustainable, high-performance energy storage, making large-scale deployment of its saltwater batteries more viable for grid and industrial applications. The only manufactured parts are the electrolyzers and flow pumps. |

|

Current Demand for Grid-Scale Energy Storage is Bigger than Production Current demand:• Huge wind turbine generators on land, windfarms in coastal regions, are turned off about 40 percent of the time since the grid can't accept their power• Large solar PV generators are routinely turned off since the grid can't accept their power• Tesla battery backlog is 10,400 orders with some huge Gigawatt orders going to Europe• Tesla Megapack annual battery profit: 52 weeks x $60 million = $3.120 Billion |

|

Consulting Includes Technology and Intellectual Property: • Schematics for plumbing and wiring together multiple tank and dry containers for battery infrastructure.• Components with supplier lists.• Anode and cathode design and material selection.• Advanced electrolyzer design options for larger-scale production. • Telephone and email support from our technology staff.• Full supplier list for all components and anode/cathode materials.• Low-cost electrolyzer design with multiple configurations for both home and commercial applications.• Low-cost 3D printing of liquid storage concepts and methodology (including automated methods).• License for Modular Blocks use and manufacturing.• Concepts and development for other applications.• Customer lists of more than $1.2 Billion USD of order interest.• Data Center Power Management and power generation using supercritical CO2 energy systems via Infinity Turbine LLC.

|

|

Consulting Our approach involves the design of cutting-edge technology which is available to builders and manufacturers, enabling us to rapidly introduce new tech into the market ahead of others. This agile strategy allows us to move quickly in bringing innovation to the forefront.First Step: Contact Salgenx LLC for a Preliminary Assessment for consulting.Second Step: Start consulting to commercialize and develop the modular saltwater battery to compete with Tesla Megapack.Third Step: If you have other applications (aside from energy storage), have us perform a Engineering Study.It's worth noting that our saltwater flow battery represents a groundbreaking advancement as the first large-scale flow battery technology of its kind to enter the market and become a real and significant competitor to the Tesla Megapack, or any grid-scale lithium based batteries.

|

|

Tesla’s Unboxing Manufacturing vs. Traditional Factory Assembly: A Game-Changer for Grid-Scale Batteries Imagine a world where massive assembly lines are obsolete. Tesla’s Unboxing Manufacturing is revolutionizing production by cutting costs, reducing waste, and accelerating scalability. How does it compare to traditional factory methods? And what does it mean for grid-scale batteries like the Salgenx Saltwater Battery vs. Tesla Megapack? Explore the future of manufacturing in this groundbreaking comparison. |

|

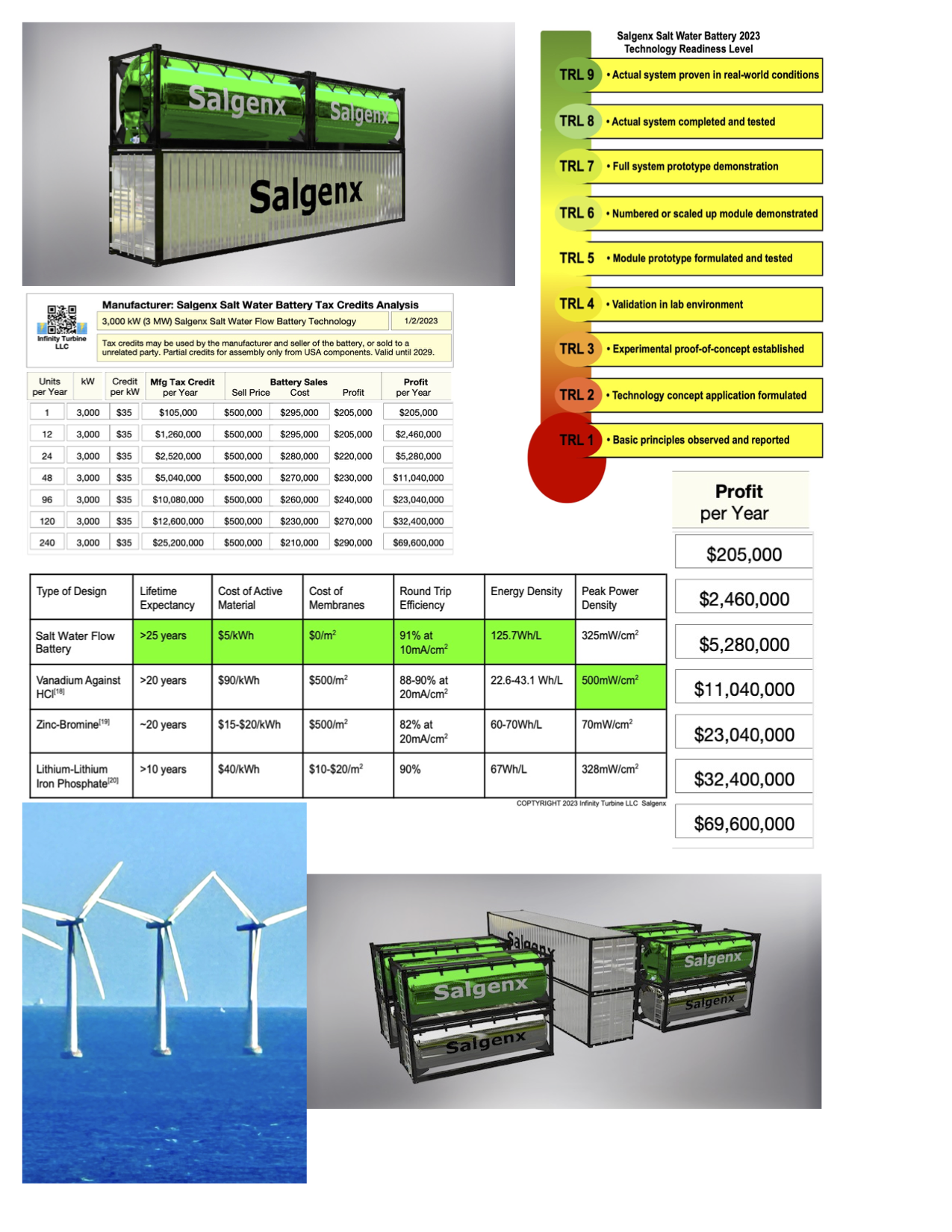

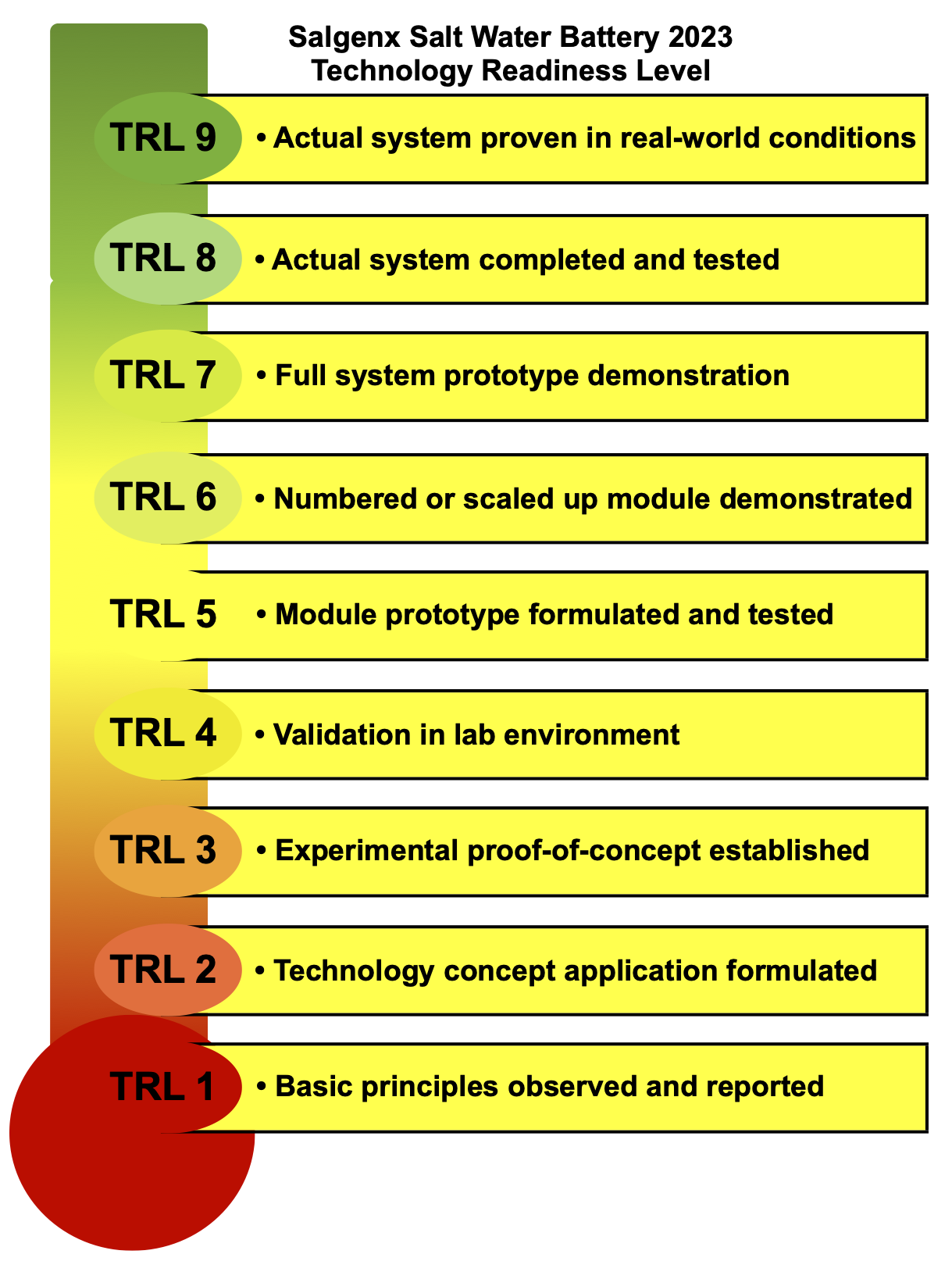

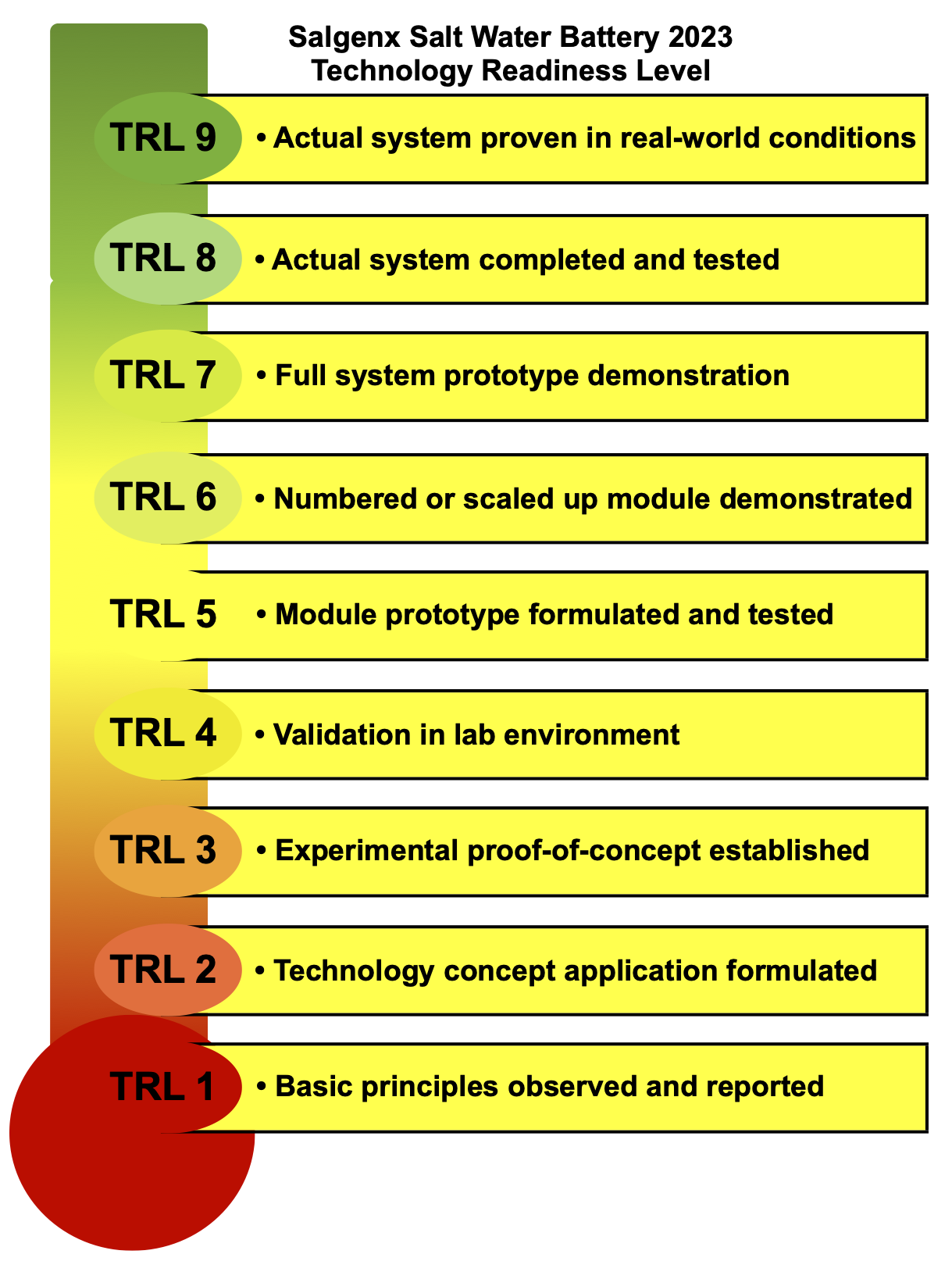

Salgenx Technology Readiness Level Graph Salgenx has achieved a Technology Readiness Level (TRL) at or above 4, as indicated by NASA's readiness level graph.Our objective in technology development is to collaborate closely with the manufacturer in order to advance the technology to TRL 6 and above, tailored to the specific system model configuration required for the desired power and voltage in the customer application.The manufacturer is responsible for progressing from TRL 6 to TRL 9, at which point the technology reaches the Manufacturing Readiness Level (MRL). This is the level of a commercial product.The TRL development of other cathode materials and applications beyond energy storage is available from Salgenx LLC. |

|

The Market for Grid Scale Batteries in Energy Storage The global grid-scale battery market is experiencing rapid growth. In 2023, the market was valued at approximately USD 6.82 billion and is projected to reach around USD 84.07 billion by 2032, with a compound annual growth rate (CAGR) of 32.2%. In November 2024, Tesla just announced it has produced 10,000 Megapacks at the Lathrop facility.Third quarter 2025 energy storage resultsTotal deployments: Tesla deployed a record 12.5 GWh of energy storage products in Q3 2025, a figure that includes both Megapack and Powerwall installations.Segment growth: This represents a substantial 81% increase from the previous quarter and demonstrates the strong growth of Tesla's energy business compared to its automotive segment, which experienced volatility in 2025.Production ramp: This record was achieved with the aid of increased production from Tesla's Lathrop Megafactory in California and the new Megapack factory in Shanghai, which began production in early 2025. Outlook for the rest of 2025Annual growth: For the full year of 2025, Tesla has projected energy storage deployments to grow by at least 50% year-over-year. |

Salgenx Technology Readiness Level Graph |

Salgenx S3000 Manufacturer Analysis |

End User Savings and Cogeneration Analysis Payback |

|

Combining Tesla Megapack Master Controller with Salgenx Cluster Mesh Grid Scale Batteries Leveraging Experience with Cost Reduction The hybrid energy storage model combining Tesla’s Megapack with Salgenx saltwater batteries offers a cost-effective and versatile solution for grid-scale energy storage. With the Megapack as the central control unit handling rapid-response and peak demand functions, and 100 Salgenx batteries providing stable, bulk storage, this setup leverages the strengths of both lithium-ion and saltwater technologies. Compared to a 100 Megapack-only system, this configuration provides similar storage capacity at a $39 million cost reduction, emphasizing both economic and operational benefits. While the Megapack ensures instant response to grid fluctuations, the Salgenx batteries contribute durable, safer, and environmentally friendly bulk storage, making the hybrid system ideal for a range of applications from peak shaving to grid resilience. This model’s scalability and safety advantages align it with the future needs of renewable energy integration, delivering a balanced approach to grid stability, economic viability, and environmental responsibility.Read More on Combining One Tesla MegaPack Controller with Salgenx Cluster Mesh Batteries |

|

Grid Scale Battery Customer Database We are also offering access to our customer database. We have about $1.2 billion USD in customer order interest. Fee based. Please email for more information. |

|

Energy Disruption Favors Non Lithium Grid Scale Battery Storage The energy industry is undergoing a major transformation, driven by the rise of grid-scale battery storage. These cutting-edge solutions are solving the biggest challenges of renewable energy—ensuring reliability, reducing costs, and making the grid more resilient. Are we on the brink of a battery-powered energy revolution? Find out how grid-scale storage is shaping the future of power and how non-lithium grid scale batteries are the winner for lower insurance rates and easing in installation and fire code concerns. |

| CONTACT TEL: +1 608-238-6001 (Chicago Time Zone) Email: greg@salgenx.com | AMP | PDF | Salgenx is a division of Infinity Turbine LLC |