Salgenx LLC • Design • Develop • Analysis TEL: 1-608-238-6001 Email: greg@salgenx.com

3 MWh Grid Scale Saltwater Flow Battery that is Self Healing More Info

|

|

Press Releases For the press releases for Salgenx Salt Water Battery, please follow the link below. |

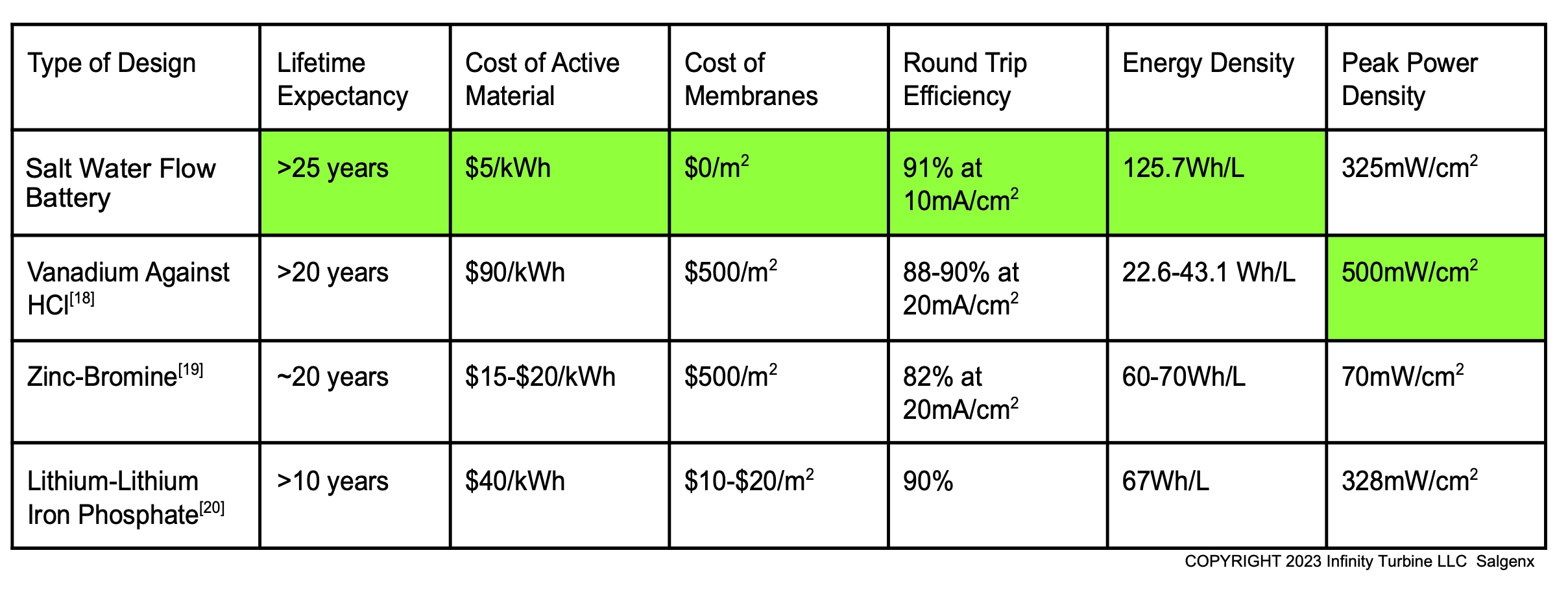

Flow Battery Comparison Chart |

|

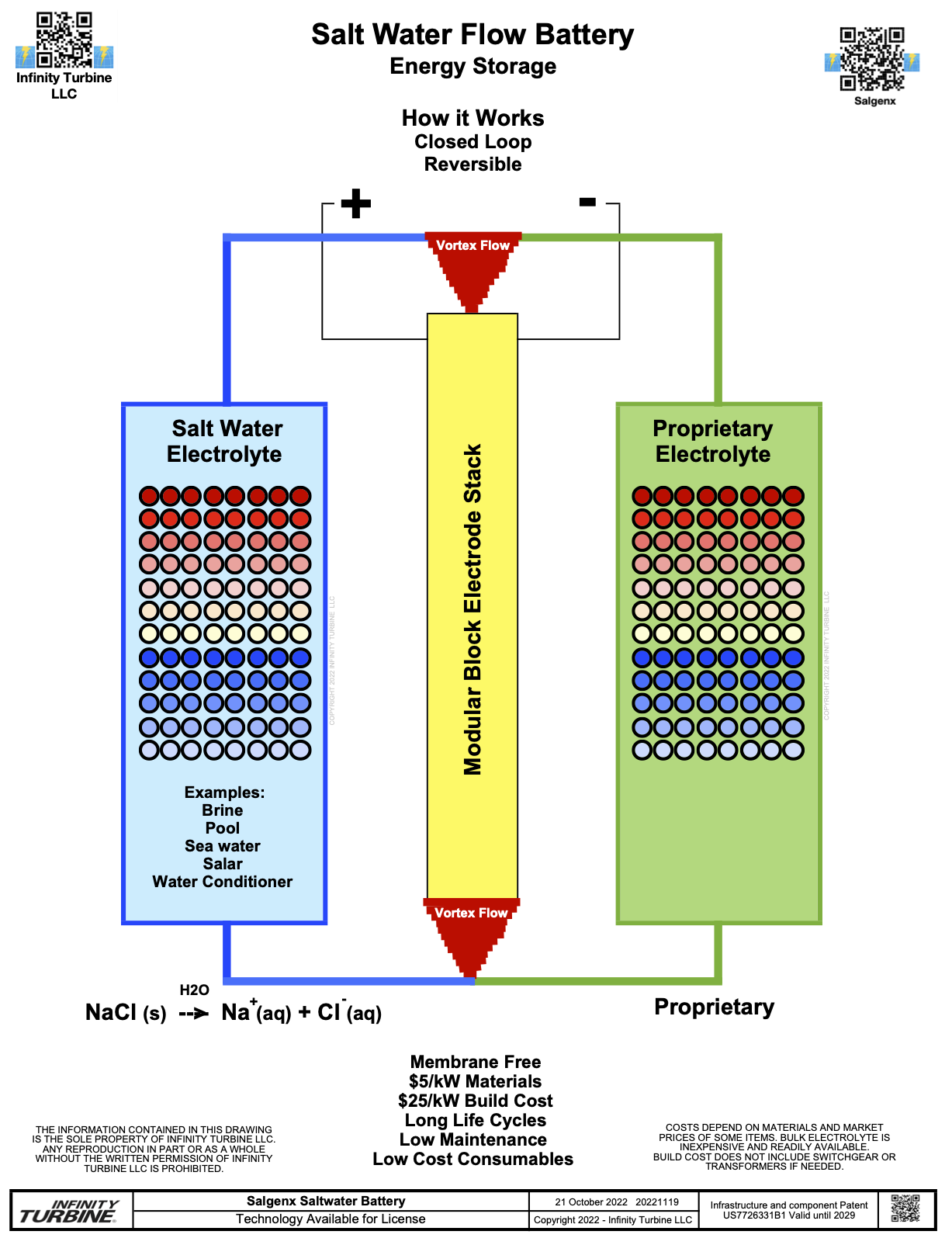

How the Salt Water Flow Battery Works Operation:1. An aqueous solution of NaCl is set in a tank and an organic liquid with high solubility of Chlorine gas and low miscibility in water is set in another tank.2. Exits from these tanks flow in separate tubing and a pump sets the flow rate for each phase.3. These two separate flows enter into a single flow (the reaction zone of the cell) and the flows will pass through and over their respective electrodes. The exit of these cells will be a flow combining the two flows. [Proprietary Device] separates the two flows and they return to their respective tanks.4. After a steady state operation is achieved, the battery applies the voltage being provided from the power source. The battery is now charging and chlorine gas is being produced in the solution. A. On the working electrode, [Proprietary catalyst] particles promote the well researched Chloride/Chlorine oxidation. Chloride ions from the NaCl aqueous solution oxidize into chlorine gas. This gas is then stripped from the aqueous phase by the organic phase.B. On the counter electrode sodium ions are ejected from an active electrode of [Proprietary catalyst] into the aqueous solution and the electrode transitions to [Proprietary catalyst]. This boosts the average cell voltage from 1.3V to 1.8V5. State of charge (SOC) is tracked by an inline concentration sensor of the organic phase. Once it reaches between 90-95 percent of its solubility limit of Chlorine gas the battery is considered charged. Pumping operation could cease. At no point is Chlorine gas outside of the closed loop system. A Chlorine sensor is provided and communicates instantaneously to command and control processor. In the case of a power failure, the system is flooded with NaCl to neutralize any Chlorine.6. The energy storage of this design comes from a large amount of trapped Chlorine gas and dissolved sodium ions. Due to the separation of the tanks, discharge over time should be incredibly limited.7. During discharge, the pumps are turned back on and a steady state operation is achieved. Then an opposite voltage is applied and the dissolved chlorine gas returns to chloride ions and the discharge is started. A. On the working electrode, dissolved chlorine gas reacts on the [Proprietary catalyst] particles back into chloride ions. The low solubility of chloride in organic phases means these ions readily return to the aqueous phase. This is a safety factor which is inherent to the closed-loop system. B. On the counter electrode sodium inserts back into the active material of the electrode.8. Once again State of Charge (SOC) is tracked by the now diminishing Chlorine concentration in the organic phase. Once it reaches 0-5 percent of its charged value, the battery is considered discharged. Pumping operation ceases.

|

|

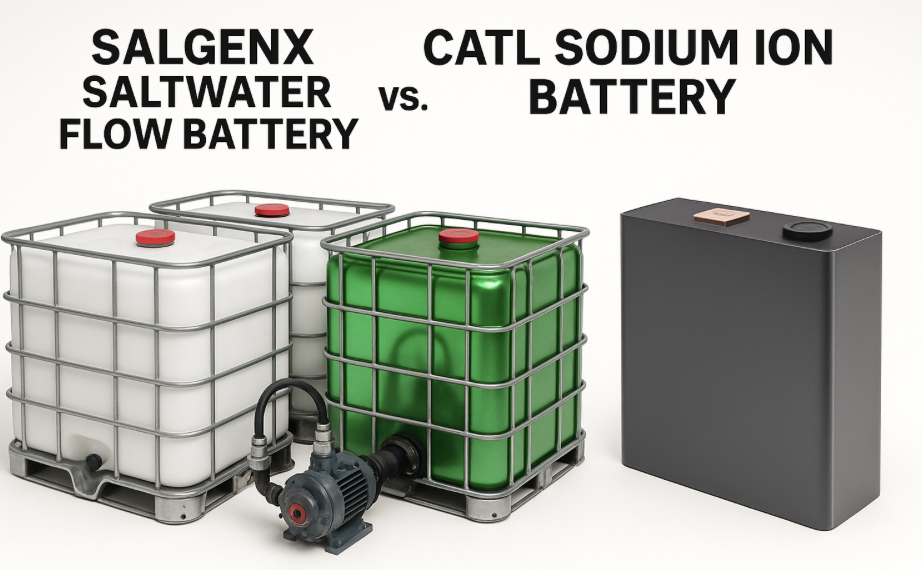

Is Saltwater Flow Battery Dead after CATL has gone into production of the Sodium Ion Battery ? Sodium ion batteries developed by CATL are gaining attention for consumer and mobility applications, but they do not replace the unique strengths of saltwater flow batteries. From unlimited cycle life to non-flammable electrolytes and independent scaling of power and energy, saltwater flow batteries continue to provide compelling advantages for large scale and long duration energy storage systems.Read More About Advantages of Saltwater Flow Batteries Compared to Sodium Ion Technology |

NACS North American Charging Standard EV (image courtesy of Tesla) |

NACS Tesla Plug for Charging AC and DC Salgenx will be offering the NACS Tesla plug as part of its connectivity options to allow direct charging of electric vehicles.From @Teslamotors #Tesla: With more than a decade of use and 20 billion EV charging miles to its name, the Tesla charging connector is the most proven in North America, offering AC charging and up to 1 MW DC charging in one slim package. It has no moving parts, is half the size, and twice as powerful as Combined Charging System (CCS) connectors.Tesla opens up its charging connector in a bid to become the North American standard |

|

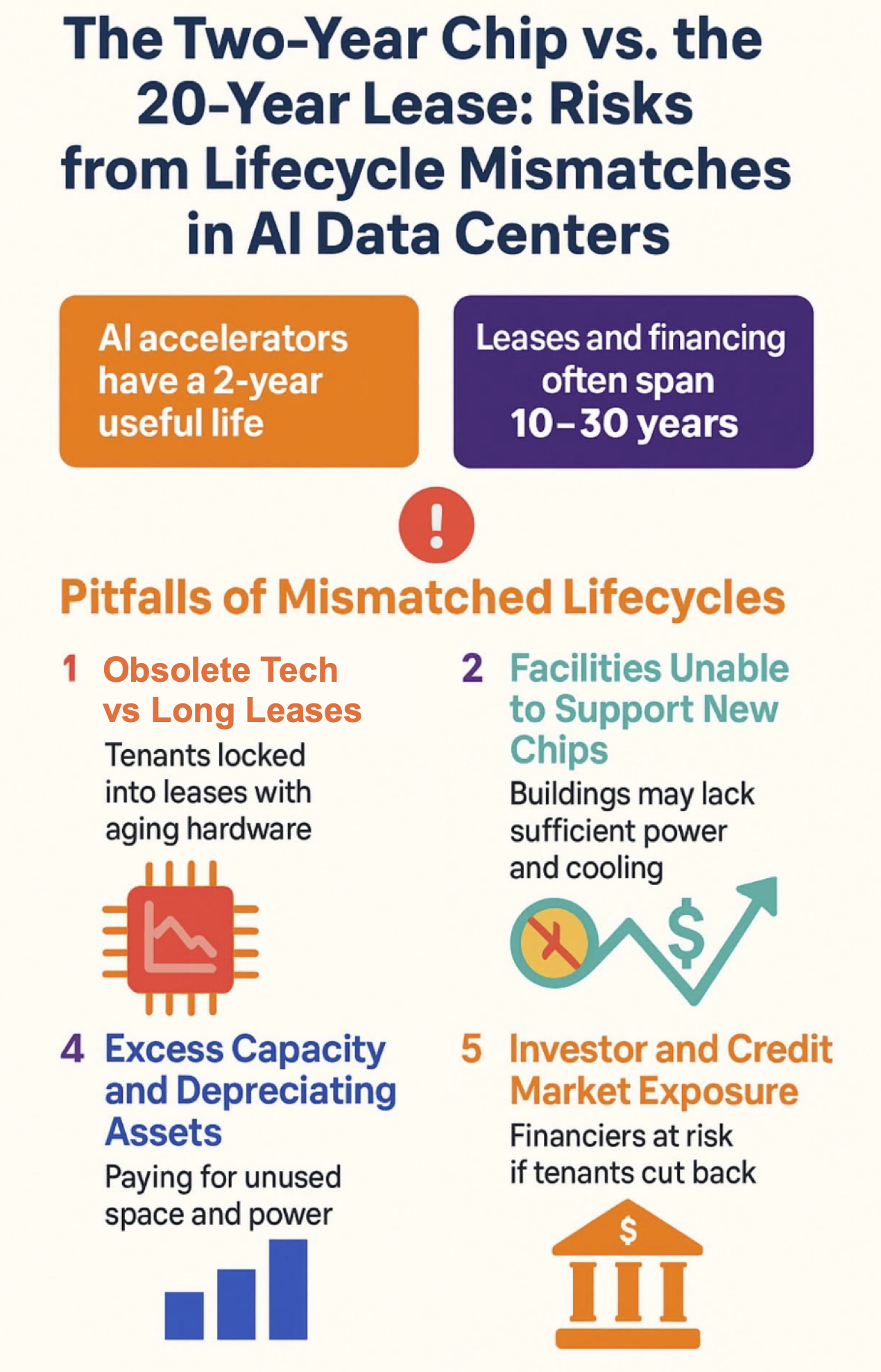

The Two-Year Problem Hiding in a Twenty-Year Industry AI chips burn bright and fast—often obsolete in just two years—yet the data centers that house them are locked into leases and financing structures lasting decades. This deep dive exposes the growing mismatch between ultra-short hardware life and long-term financial commitments in the AI infrastructure boom. From stranded facilities to SPV risk cascades, we explore how today’s rapid chip churn could collide with tomorrow’s 20-year obligations—and what happens when the economics of AI finally slow down.The Two-Year Chip vs. the 20-Year Lease: The Hidden Fragility of AI Data Center Financing |

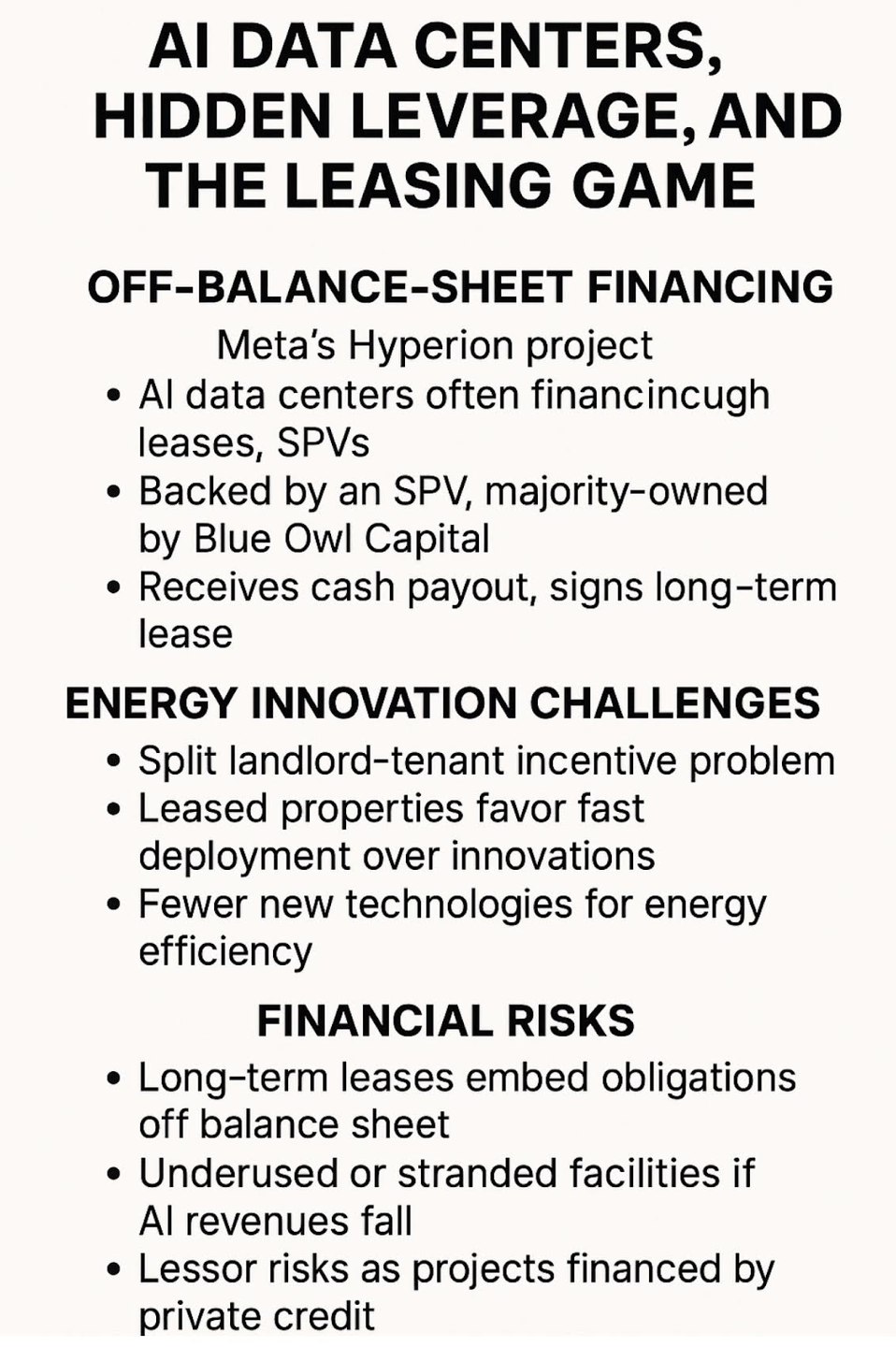

|

The New AI Gold Rush: Compute Now, Own Later AI data centers are exploding in size—and in hidden risk. Behind the shiny GPU racks, much of today’s AI infrastructure is financed off-balance sheet through leases and opaque SPVs, with Meta’s Hyperion campus as the flagship example. This article unpacks how that Enron-style financial engineering shapes decisions about cooling, energy efficiency, and waste-heat recovery—and why leased facilities may be slow to adopt breakthrough technologies. It also explores what happens if AI revenues falter while long-term lease obligations keep piling up. Are we quietly building the next leverage bubble in the cloud?AI Data Centers, Hidden Leverage and the Leasing Game: Lessons From Meta’s Hyperion Strategy |

Build Your Own Brand |

CATL Sodium Ion vs Saltwater Flow Battery Salgenx is not competing with lithium or sodium-ion batteries on short-duration price or energy density; it is purpose-built for long-duration, non-flammable, serviceable energy storage where safety, lifetime throughput, and resilience matter more than compact packaging. By decoupling power from energy through a saltwater flow architecture, Salgenx enables economical six to twenty-four hour storage, simplified permitting near occupied buildings, and long service life through stack refurbishment rather than full battery replacement. As sodium-ion batteries accelerate adoption in commodity one to four hour applications, Salgenx occupies a defensible niche as energy infrastructure for commercial, industrial, municipal, and microgrid customers seeking dependable, long-life storage with lower risk, predictable operating costs, and expandable capacity over time.Salgenx is intentionally not positioned as a universal battery solution. Salgenx clearly identifies applications where short-duration, high–energy-density batteries such as lithium-ion or sodium-ion are the better choice, including space-constrained sites, one to four hour peak shaving, and fast-deploy portable systems. By explicitly defining where Salgenx is not the optimal fit, they are a trusted long-duration energy infrastructure partner rather than a commodity battery vendor. |

Advanced Electrolyzer Design Has Potential of Graphene (reduction of Graphite) and Cement Production (reduction of limestone without CO2 emissions) Simultaneously While Charging |

Fastest Path to a 3 MWh Grid-Scale Saltwater Flow Battery: Zinc-Chlorine vs NTP-Based Architectures Which saltwater flow battery chemistry reaches grid-scale commercialization first? This article compares zinc metal and NTP-based chlorine flow batteries across cost, efficiency, manufacturing complexity, and bankability to determine the fastest and most cost-effective path to a 3 MWh system.IntroductionGrid-scale energy storage increasingly demands systems that are safe, low-cost, scalable, and free from constrained materials. Saltwater flow batteries, particularly chlorine-based systems, have re-emerged as a compelling alternative to lithium-ion due to their use of abundant materials, non-flammable electrolytes, and long cycle life.Recent research has demonstrated a membrane-free chlorine flow battery architecture with exceptionally low projected material cost. Within this platform, two negative electrode strategies emerge as candidates for commercialization:1. Zinc metal negative enabled by a ZnCl2 additive2. NaTi2(PO4)3 (NTP) intercalation negative without zinc additiveThis article evaluates both approaches for a 3,000 kWh grid-scale containerized system and determines which offers the fastest, lowest-risk, and most cost-effective path to market.System Architecture OverviewBoth battery variants share a common core architecture:• Aqueous NaCl electrolyte• Chlorine redox at the positive electrode• Closed-loop chlorine handling using an immiscible organic carrier• Membrane-free stack design• Modular stacks arranged into a roughly 900 V DC busThe primary difference lies in the negative electrode chemistry and its implications for voltage, efficiency, manufacturing, and cost.Option A: Zinc-Chlorine Flow Battery with ZnCl2 AdditiveElectrochemistry• Positive: Cl2 / Cl minus• Negative: Zn2 plus / Zn metal• Nominal cell voltage: approximately 1.9 VAdding ZnCl2 to the electrolyte enables reversible zinc plating and stripping, replacing the need for a solid-state intercalation cathode.Manufacturing and Commercial Advantages• Zinc metal is a commodity material available as sheet, foil, or plated substrates (it is also available at Home Depot).• Electrode fabrication is simple and scalable• No high-temperature ceramic synthesis or vapor deposition steps• Aligns with historical zinc-halogen battery manufacturing experienceThe zinc electrode can be designed as a serviceable component, enabling predictable maintenance rather than end-of-life replacement.Risks• Zinc dendrite formation must be controlled through current density, flow design, and electrolyte management• Coulombic efficiency must be validated at scaleOption B: Chlorine Flow Battery with NTP CathodeElectrochemistry• Positive: Cl2 / Cl minus• Negative: NaTi2(PO4)3 (NTP)• Nominal cell voltage: approximately 1.8 VNTP is a NASICON-type insertion material offering good rate capability and stable cycling.Manufacturing and Commercial Challenges• NTP synthesis requires high-temperature calcination• Conductive carbon coating is necessary, typically involving additional thermal processing or vapor deposition• Powder processing and electrode fabrication add complexity and capital costWhile technically elegant, NTP introduces a more complex supply chain and slower ramp to volume production.Costed BOM Comparison for a 3 MWh ContainerUsing the Nature Communications estimate of approximately $5 per kilowatt-hour as a floor for active materials, and legacy zinc-chlorine plant data as a balance-of-plant sanity check, the following system-level costs emerge:• Zinc-Chlorine system total installed cost: approximately xxxxx dollars• NTP-based system total installed cost: approximately xxxxx dollarsThis corresponds to:• Zinc system: approximately xx dollars per kWh installed• NTP system: approximately xxx dollars per kWh installedIn both cases, balance-of-plant, power electronics, and safety systems dominate total cost, not the electrochemistry itself.Efficiency and Cost-Per-Delivered-kWhEfficiency must be evaluated alongside capital cost to assess true economic performance.• NTP-based systems have demonstrated laboratory-scale energy efficiency exceeding 90 percent• Zinc-based systems typically operate in the 70 to 75 percent range when system parasitics are includedWhen adjusted for efficiency:• Zinc system effective cost per delivered kWh: approximately xx to xx dollars• NTP system effective cost per delivered kWh: approximately xx to xxx dollarsThis indicates that while NTP offers higher efficiency, the zinc system compensates with lower upfront cost and faster manufacturability.Fastest Path to Market AssessmentFrom a commercialization standpoint, the decisive factors are manufacturability, supply chain simplicity, and execution risk.• Zinc metal electrodes eliminate the need for specialty ceramic powders and carbon coating processes• Anodes are already mass-produced industrial components• The zinc system supports a service-based maintenance model familiar to utilitiesThe NTP system, while attractive for future optimization, introduces additional process steps that slow time to first deployment.Commercial VerdictFor a first-generation, grid-scale saltwater flow battery:• The zinc-chlorine system with ZnCl2 additive is the fastest to market• It offers the lowest installed cost• It presents the least manufacturing risk• It enables early revenue and field validationThe NTP-based system is best positioned as a second-generation or premium offering once manufacturing scale and customer confidence are established.ConclusionSaltwater flow batteries based on chlorine chemistry present a credible, scalable alternative to lithium-ion for long-duration grid storage. Between the two leading negative electrode options, zinc metal offers the most direct path to commercialization for a 3 MWh containerized system. Its simplicity, cost advantage, and alignment with existing industrial practices outweigh the efficiency advantage of NTP in early deployments.A dual-track strategy is recommended: deploy zinc-based systems first to capture market share and operational data, while continuing development of NTP-based systems for future high-efficiency products.References1. Hou et al. High Energy and Low Cost Membrane Free Chlorine Flow Battery. Nature Communications, 2022.2. Detroit Edison and Energy Development Associates. Zinc Chlorine Battery Utility Study and Cost Analysis, 1976 to 1977.3. Bard and Faulkner. Electrochemical Methods Fundamentals and Applications. Wiley.4. U.S. Department of Energy. Grid Energy Storage Technology and Cost Characterization Reports.

|

Search 3000 Pages of Lithium Ion Battery Fire Hazard Information |

Infinity Turbine Radial Outflow Turbine Generator which can be used simultaneously as a heat pump |

As a simultaneous Thermal Storage Device TES Considered a hybrid between a standard flow battery and a thermal storage device, the battery provides simultaneous heat or cold liquid storage as well as electrical energy storage.The Cogen Battery has a variety of applications which include:-storage of thermal energy (heating or cooling) from unused thermal resources-storage of electrical power for backup power and grid strength-utility grid power rate mining opportunities to store off-peak low cost power for later use during demand (on-peak) hours-storage of thermal energy for Organic Rankine Cycle (ORC) power production while simultaneously storing the electrical output from the turbine generator-using off-peak low cost power to make heating and cooling for later use-reducing peak demand utility rates by peak energy shaving

|

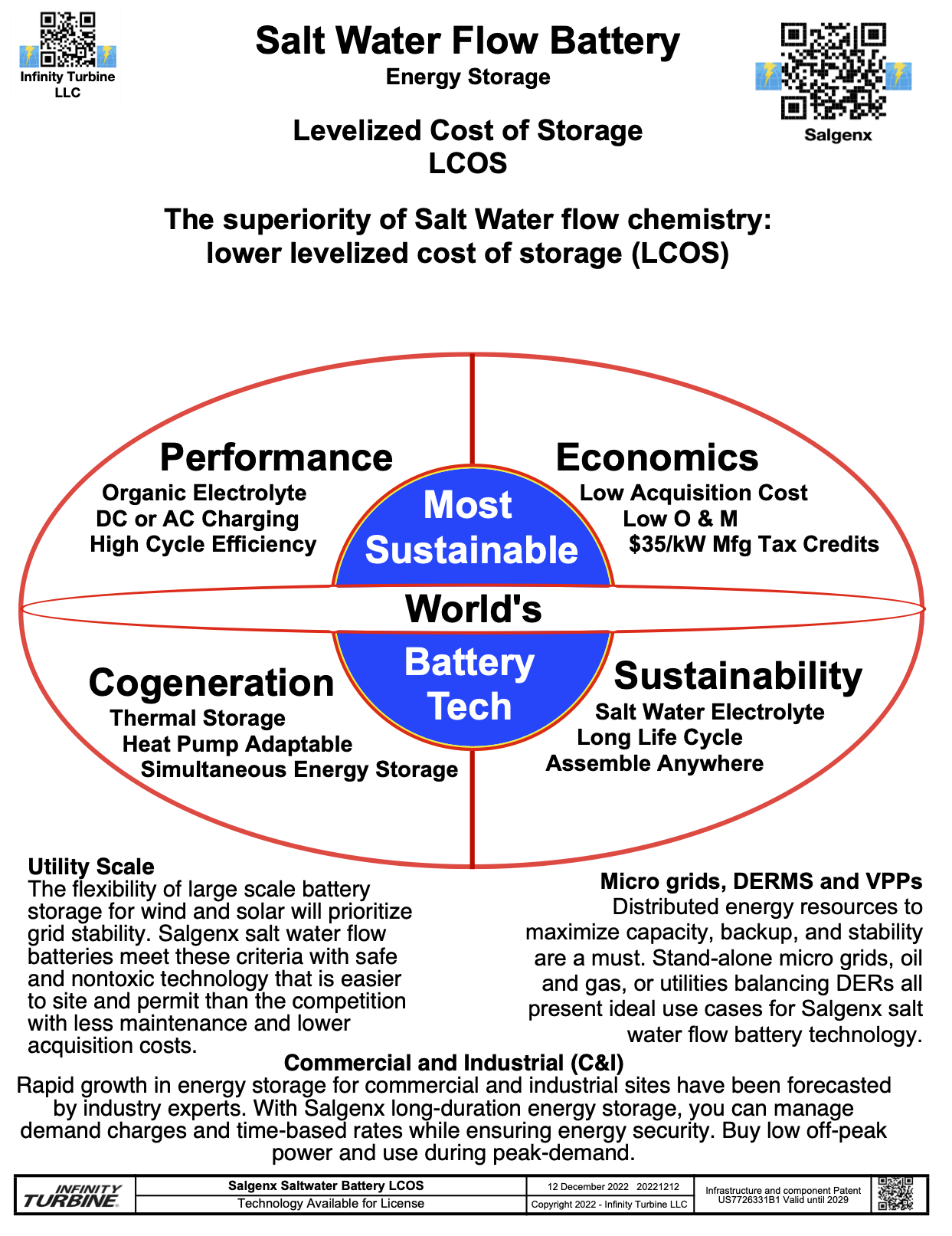

Salt Water Flow Battery Levelized Cost of Storage |

Levelized Cost of Storage LCOS The superiority of Salt Water flow chemistry: lower levelized cost of storage (LCOS).Utility ScaleThe flexibility of large scale battery storage for wind and solar will prioritize grid stability. Salgenx salt water flow batteries meet these criteria with safe and nontoxic technology that is easier to site and permit than the competition with less maintenance and lower acquisition costs.Micro grids, DERMS and VPPsDistributed energy resources to maximize capacity, backup, and stability are a must. Stand-alone micro grids, oil and gas, or utilities balancing DERs all present ideal use cases for Salgenx salt water flow battery technology.Commercial and Industrial (C&I)Rapid growth in energy storage for commercial and industrial sites have been forecasted by industry experts. With Salgenx long-duration energy storage, you can manage demand charges and time-based rates while ensuring energy security. Buy low off-peak power and use during peak-demand. |

With every 20 to 50 AI queries, approximately half a liter of fresh water is lost in the form of steam emissions |

Note: The Cavgenx system is designed to be integrated into the Salgenx battery, which can be used as a heat sink for AI data center cooling and battery backup.Introduction to Data Center Cooling which uses Evaporative Cooling and lots of WaterIn our digitally-driven world, artificial intelligence (AI) has become an integral part of our daily lives, from voice assistants and recommendation algorithms to chatbots and language models. We often use AI systems without realizing the environmental impact they may have. A recent study conducted by the University of California, Riverside, sheds light on a concerning aspect of AI technology: its hidden water footprint. Each time you run a ChatGPT artificial intelligence query, you unknowingly contribute to the depletion of our already overstressed freshwater resources.The Water Footprint of AIThe research from the University of California, Riverside, has revealed a startling fact: running AI queries that rely on cloud computations in data processing centers consumes significant amounts of freshwater resources. With every 20 to 50 queries, approximately half a liter (around 17 ounces) of fresh water is lost in the form of steam emissions. This might not seem like much on an individual basis, but the cumulative impact of billions of AI queries worldwide is a cause for concern...

Making AI Less Thirsty: Uncovering and Addressing the Secret Water Footprint of AI Models |

|

Comprehensive Guide to Lithium-Based Energy Storage Systems: Risks, Safety, and Best Practices This comprehensive report provides a technical analysis of large-scale lithium energy storage systems, focusing on 1 MW+ containerized solutions. It delves into the risks of thermal runaway, fire hazards, and toxic gas emissions, along with strategies for fire prevention, monitoring, and site-specific installation considerations. Additionally, it covers the impact of lithium fires on insurance costs and outlines best practices for safety, scalability, and operational efficiency. Emerging technologies and regulatory frameworks are also discussed to provide actionable insights for manufacturers, operators, and policymakers. |

| CONTACT TEL: +1 608-238-6001 (Chicago Time Zone) Email: greg@salgenx.com | AMP | PDF | Salgenx is a division of Infinity Turbine LLC |