|

|

|

|

Unveiling the Wholesale Value of Tomatoes, Leafy Greens, Peppers, and Microgreens

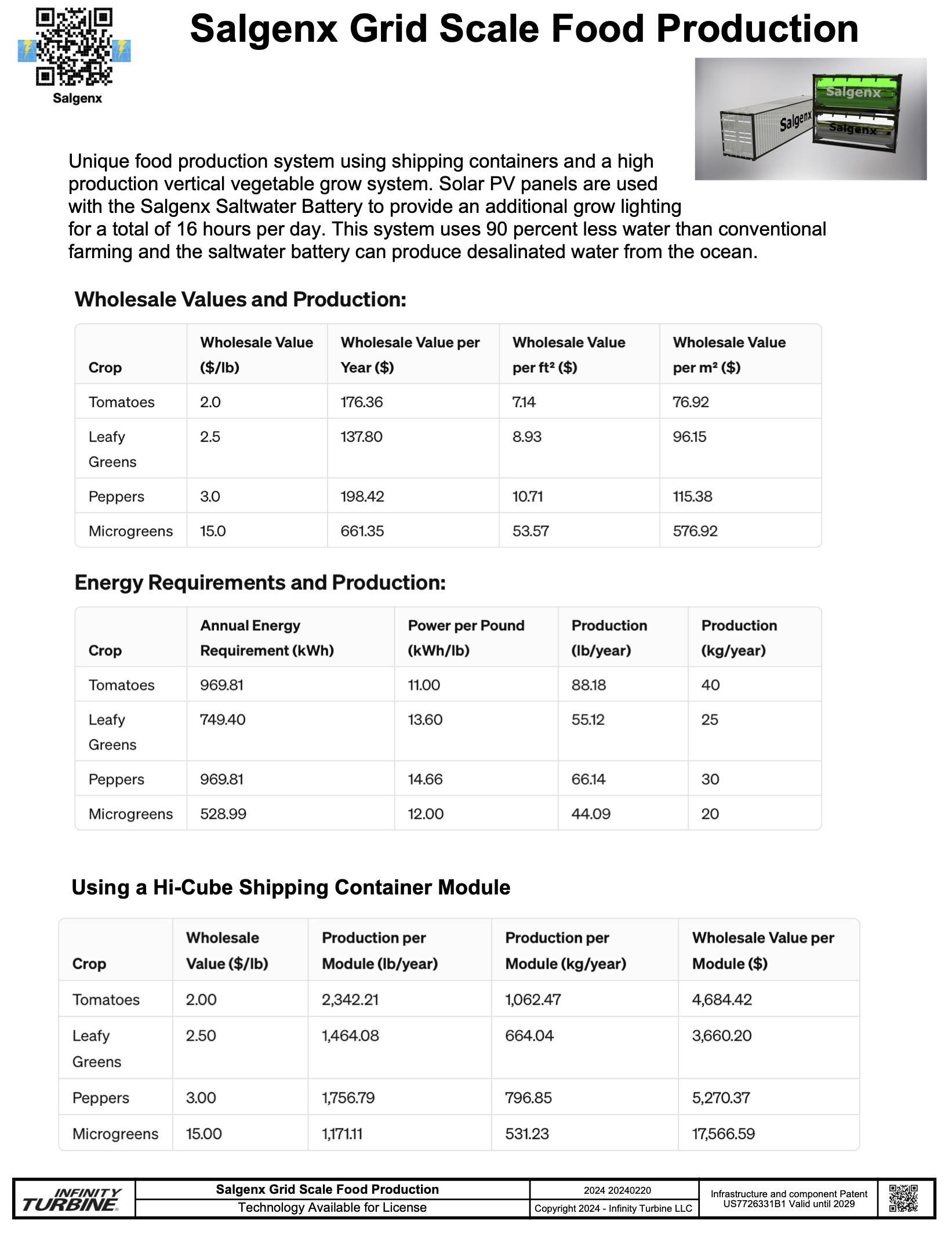

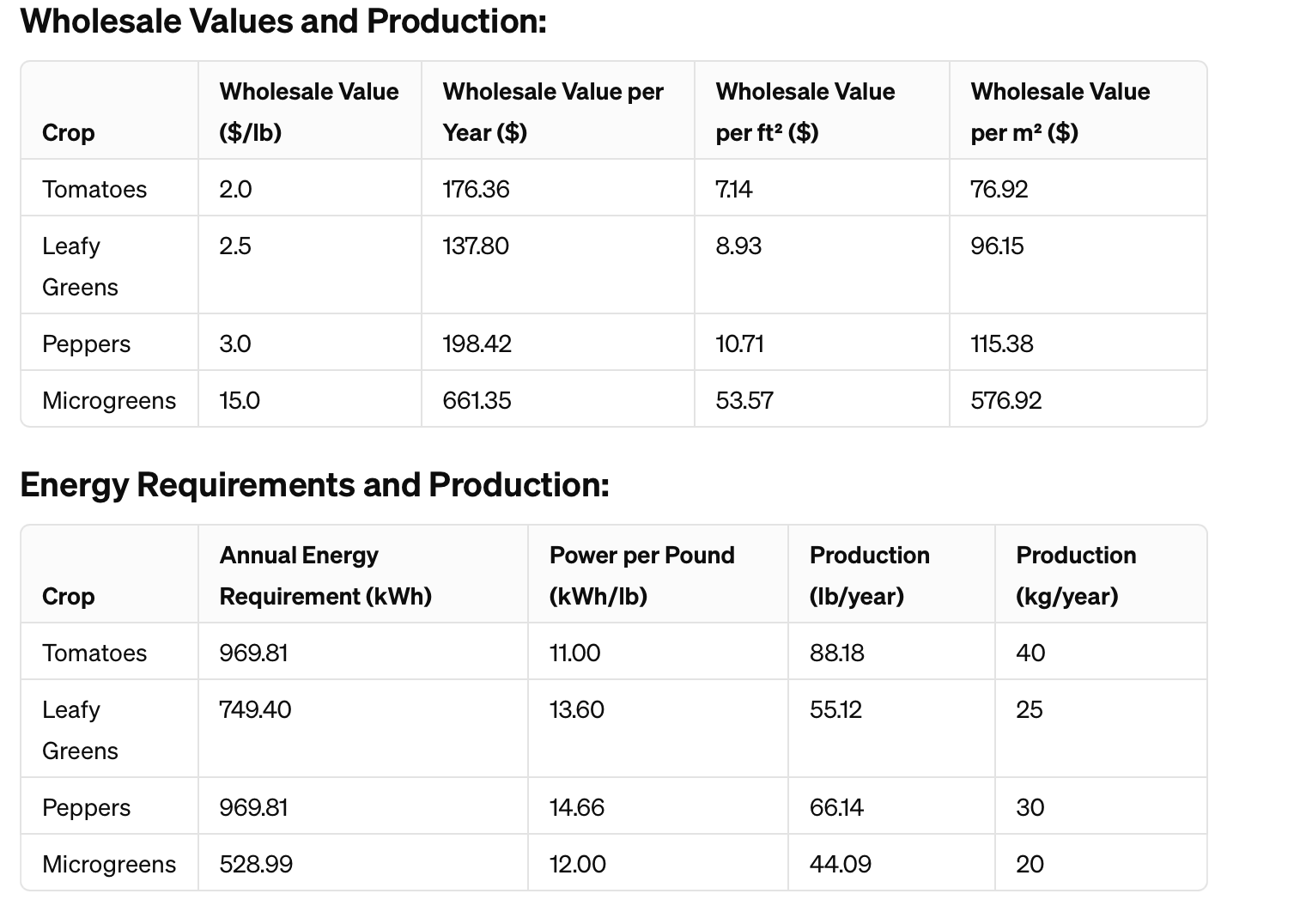

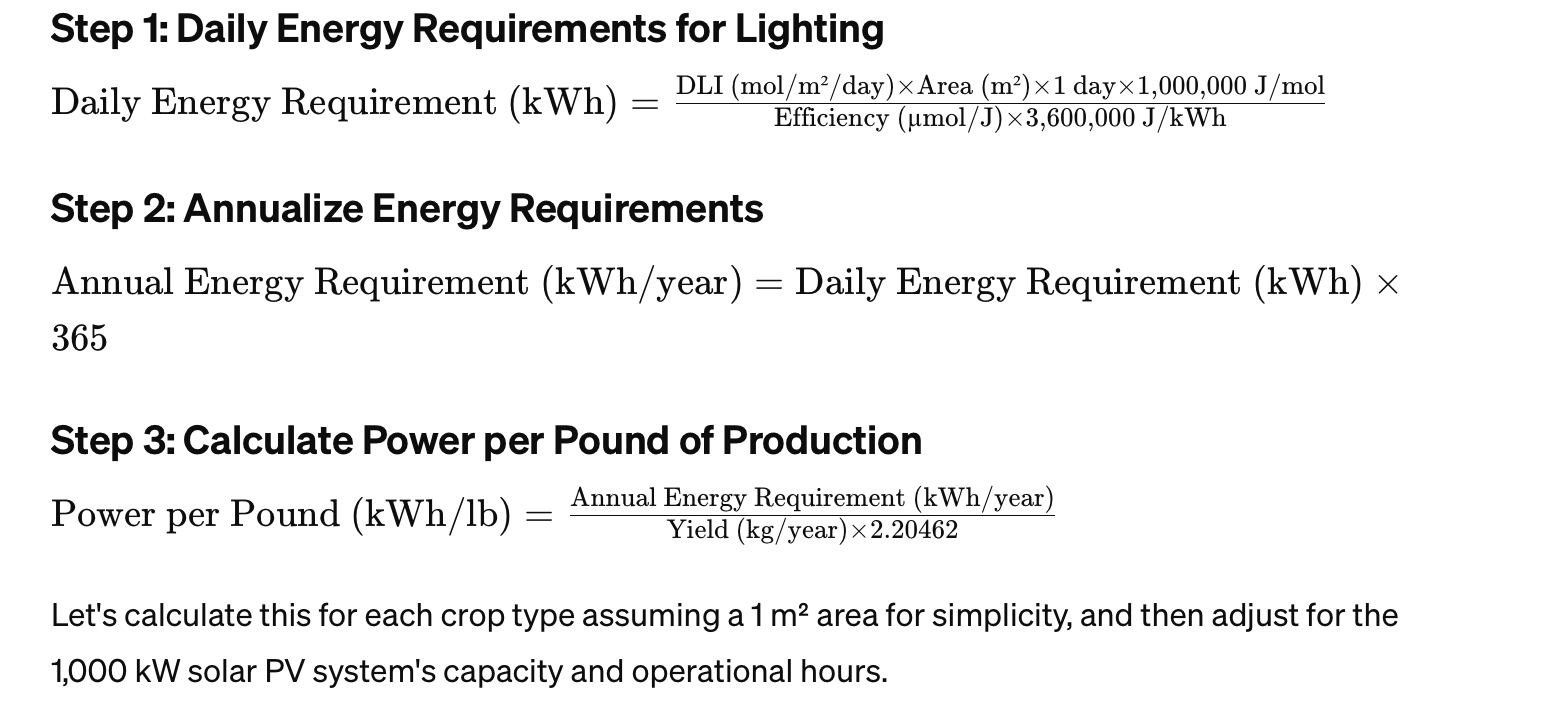

In the realm of agricultural production, understanding the market dynamics and wholesale value of crops is crucial for farmers and agribusinesses aiming to maximize their returns. Tomatoes, leafy greens, peppers, and microgreens represent a significant segment of the vegetable market, each with its unique demand and pricing structure. This article delves into the current wholesale value of these crops, providing insights into their market positioning and potential profitability for producers.Tomatoes: The Versatile StapleTomatoes are a cornerstone of global cuisine, making them a staple in both retail and wholesale markets. The wholesale value of tomatoes can vary widely based on variety (e.g., beefsteak, cherry, heirloom), quality, and season. On average, wholesale prices for tomatoes range from $0.75 to $2.00 per pound. Factors such as organic certification and local sourcing can command higher prices, with premiums of up to 20-30% over conventional tomatoes.Leafy Greens: The Green GoldLeafy greens, encompassing varieties like lettuce, spinach, kale, and arugula, are in constant demand due to their health benefits and versatility. The wholesale value for leafy greens typically ranges from $1.00 to $2.50 per pound, with organic and specialty varieties (e.g., baby spinach or kale) fetching higher prices. Seasonality plays a significant role, with prices peaking during off-season periods due to reduced availability.Peppers: A Spectrum of Flavors and PricesPeppers, from sweet bell peppers to hot chilis, offer a wide range of flavors and uses, reflected in their market prices. Wholesale prices for bell peppers average between $1.00 and $3.00 per pound, with variations based on color (red, yellow, and green) and origin. Hot peppers, due to their lower volume but specialized demand, can see even greater price variability, often exceeding $3.00 per pound for exotic or particularly spicy varieties.Microgreens: The Premium NicheMicrogreens have surged in popularity as a premium product, prized for their intense flavors and nutritional content. Due to their labor-intensive cultivation and short shelf life, microgreens command higher wholesale prices, typically ranging from $10 to $30 per pound, depending on the variety (e.g., radish, pea shoots, arugula). Their high value makes them an attractive crop for producers focusing on niche markets and direct sales to gourmet restaurants and health-conscious consumers.Market Trends and ConsiderationsWhile these price ranges offer a snapshot of the current market, several factors can influence the wholesale value of these crops:• Seasonality and Availability: Prices can fluctuate significantly with changes in supply and demand, particularly for crops grown in outdoor conditions subject to weather variations.• Quality and Certification: Premium prices are often associated with higher quality standards, organic certification, and sustainable farming practices.• Market Channels: Direct sales to restaurants, specialty stores, and farmers' markets can yield higher returns compared to traditional wholesale channels.ConclusionThe wholesale value of tomatoes, leafy greens, peppers, and microgreens illustrates the diverse opportunities within the agricultural sector for producers to tap into. By understanding market demands, pricing structures, and the factors influencing value, growers can strategically position their products for maximum profitability. As consumer preferences continue to evolve towards healthier and sustainably produced foods, the potential for premium pricing and niche market development remains robust, offering promising avenues for growth and innovation in the agricultural industry.

|