Reverse Osmosis (RO) system needed to desalinate 24,000 liters of seawater over 6 hours

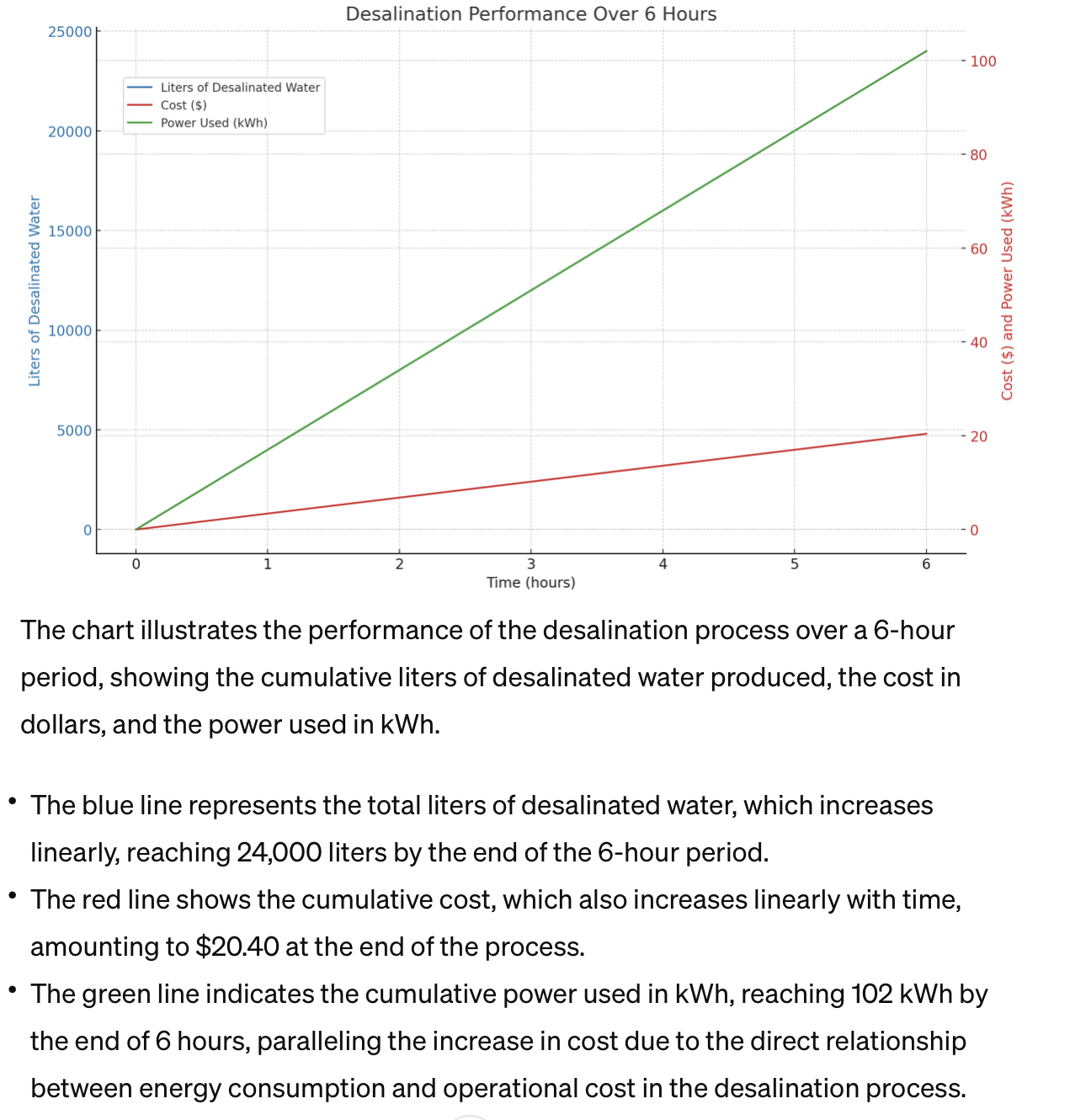

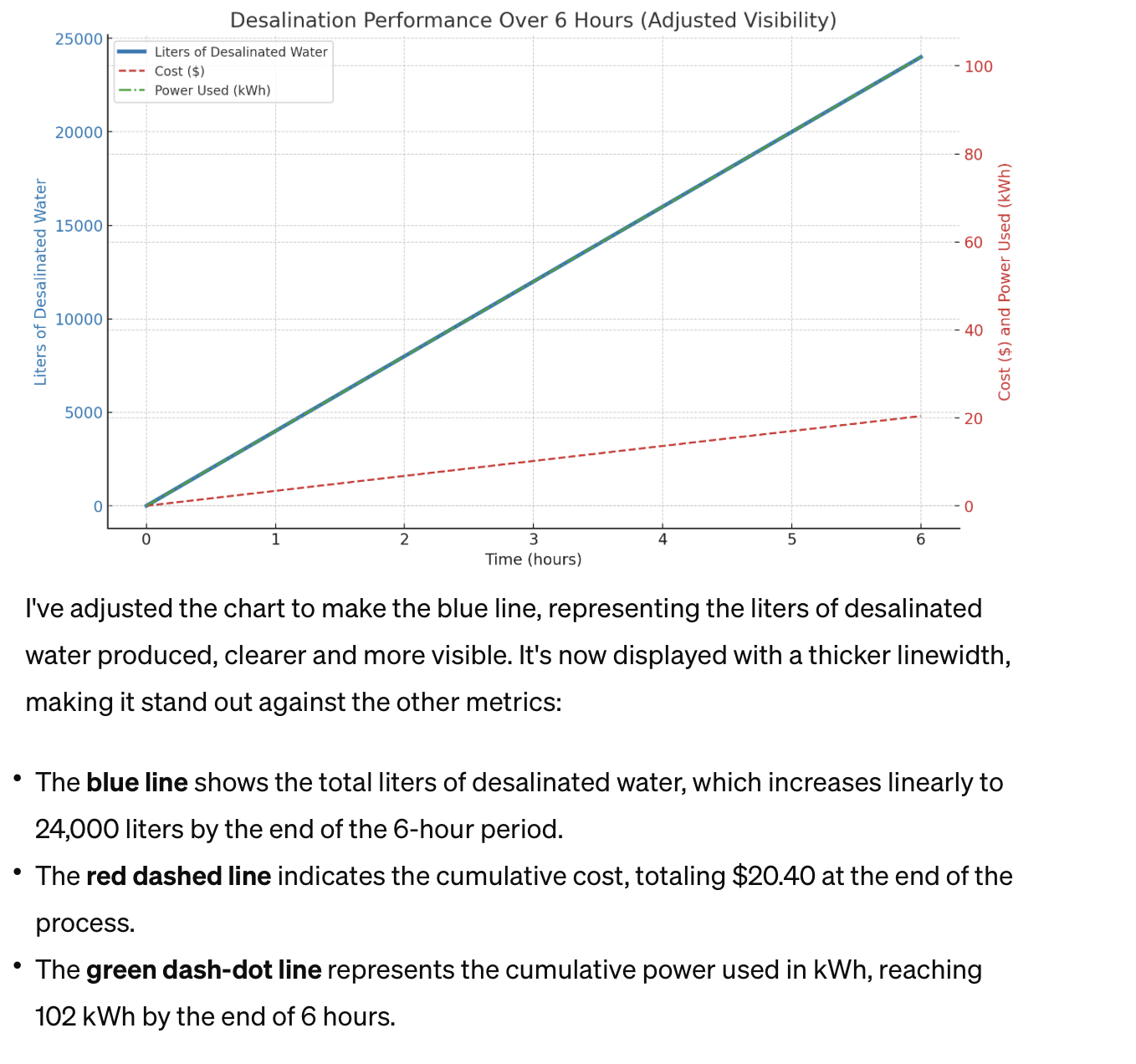

To determine the size of a Reverse Osmosis (RO) system needed to desalinate 24,000 liters of seawater over 6 hours, we need to calculate the system's required production rate in liters per hour (L/h). Once the production rate is known, we can estimate the power consumption based on typical energy requirements for seawater desalination through RO systems. Then, we'll address the cost of power, the salinity of the brine output, and approximate maintenance costs.1. RO System Size Requirement\[ \text{Required Production Rate} = \frac{\text{Total Volume to Desalinate}}{\text{Operation Time}} \]2. Power Consumption and CostThe energy consumption of RO systems for seawater desalination typically ranges from 3 to 5.5 kWh per cubic meter of water produced, depending on factors like the system's efficiency, the feed water's salinity, and the desired quality of the product water. For this estimation, we'll use a mid-range value.\[ \text{Energy Consumption (kWh)} = \text{Volume in Cubic Meters} \times \text{Energy Use per Cubic Meter} \]The cost of power can then be calculated using the given electricity rate.3. Salinity of BrineThe salinity of the brine output from an RO system is typically about twice the salinity of the input seawater, which is around 35,000 ppm (parts per million) for open ocean water. This means the brine could be around 70,000 ppm. However, this value can vary based on specific system configurations and operating parameters.4. Maintenance CostsThe maintenance costs for RO systems can include membrane replacement, cleaning, and labor. These costs can vary widely but are often estimated as a percentage of the initial system cost per year. For a rough estimate, maintenance might range from 1% to 5% of the initial system cost annually.Let's perform the calculations for the production rate, energy consumption, and power cost first.To desalinate 24,000 liters of seawater over 6 hours, you would need a Reverse Osmosis (RO) system with a production capacity of 4,000 liters per hour.For this operation, the energy consumption would be approximately 102 kWh for the entire 6-hour period. Given an electricity cost of $0.20 per kWh, the cost to run the system for this period would be $20.40.Salinity of Brine and Maintenance Costs• Salinity of Brine: The output brine's salinity would typically be around twice that of the input seawater, so if starting with standard ocean water at about 35,000 ppm, the brine could have a salinity of approximately 70,000 ppm. This figure can vary based on the system's operation and the specific seawater being processed.• Maintenance Costs: These can vary significantly based on the system's size, design, and operating conditions. For a broad estimate, if maintenance costs range from 1% to 5% of the system's initial cost annually, and assuming an initial cost could range from tens to hundreds of thousands of dollars for a system of this capacity, the maintenance cost for running the system one cycle per day could be from a few hundred to several thousand dollars per year. Without more specific data on the system's cost and maintenance requirements, it's challenging to provide a precise figure. Maintenance tasks typically include membrane replacement, system cleaning, and various repairs, all of which contribute to the overall operational costs.For detailed cost estimates, including the exact maintenance costs, consulting with RO system suppliers or manufacturers would provide the most accurate figures based on the specific system design and operational parameters you plan to use.