On Demand versus the Tesla Giga Factory

Salgenx LLC • Sales • Licensing • Consulting TEL: 1-608-238-6001 Email: greg@salgenx.com

Zinc Based Electrodes for Chlorine Flow Battery Offer Higher Voltage and Better Energy Density Offering ultra-low cost build and up to 40,000 cycles at 93 percent efficiency... Zinc is available in rolls at Home Depot

Zinc-powered, saltwater-driven — the affordable flow battery redefining grid storage. Low-cost zinc electrodes meet limitless saltwater energy.

A breakthrough in sustainable storage — zinc and saltwater in perfect balance. From seawater to megawatt — zinc makes energy storage clean and cheap.

No lithium, no fire risk, no compromise — just sustainable power. Turning saltwater into savings — one zinc electrode at a time.

The lithium alternative the world’s been waiting for. Zinc is the new gold in battery innovation.

$35 Tax Credit per kWh Until 2030 Reliable. Recyclable. Remarkably affordable. That’s zinc-based energy.

IT1000 Portable Power for Data Centers 1 MW Clean Power using Natural Gas, Solar Thermal, or Waste Heat

|

Factory Optimization and Machinery

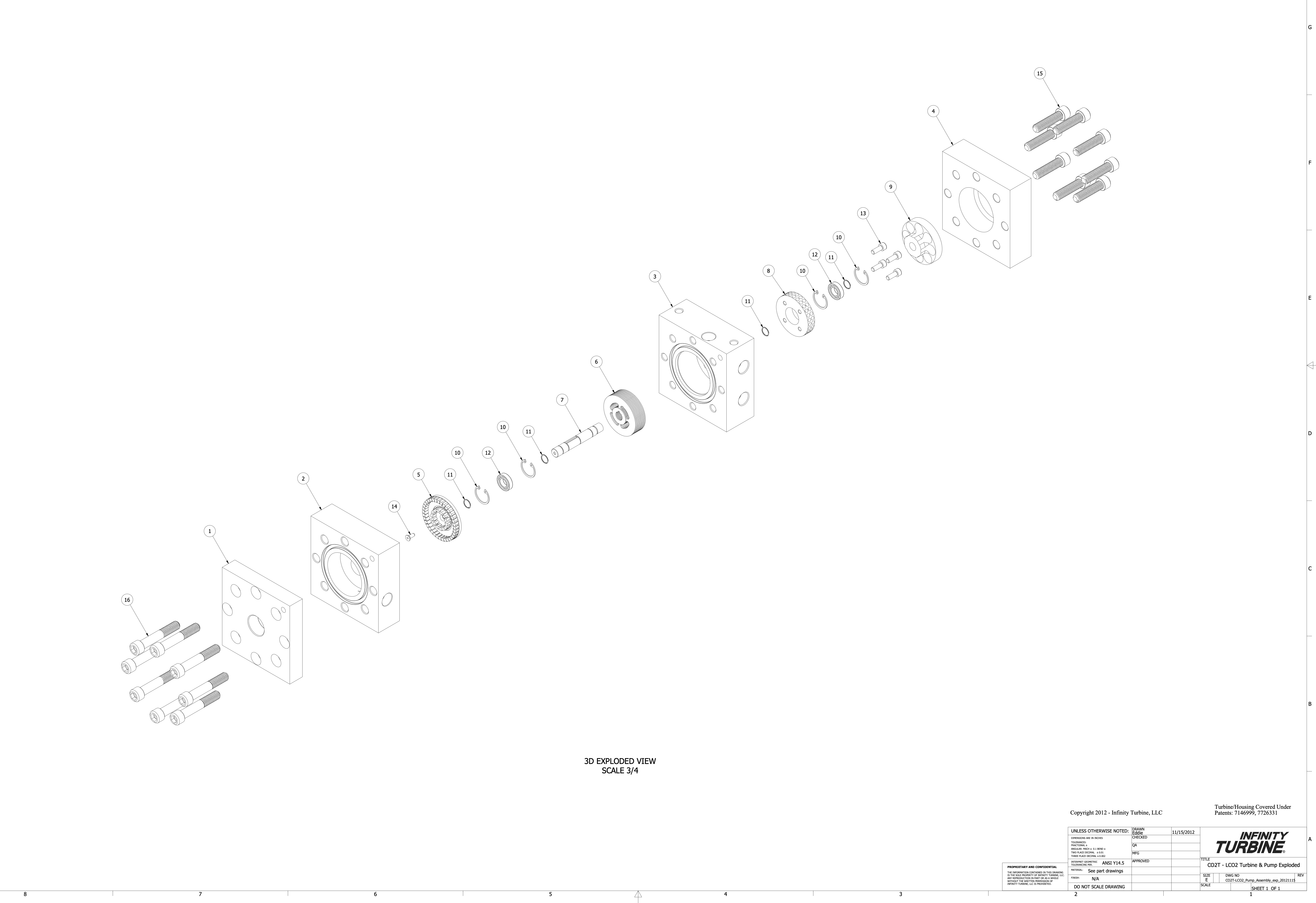

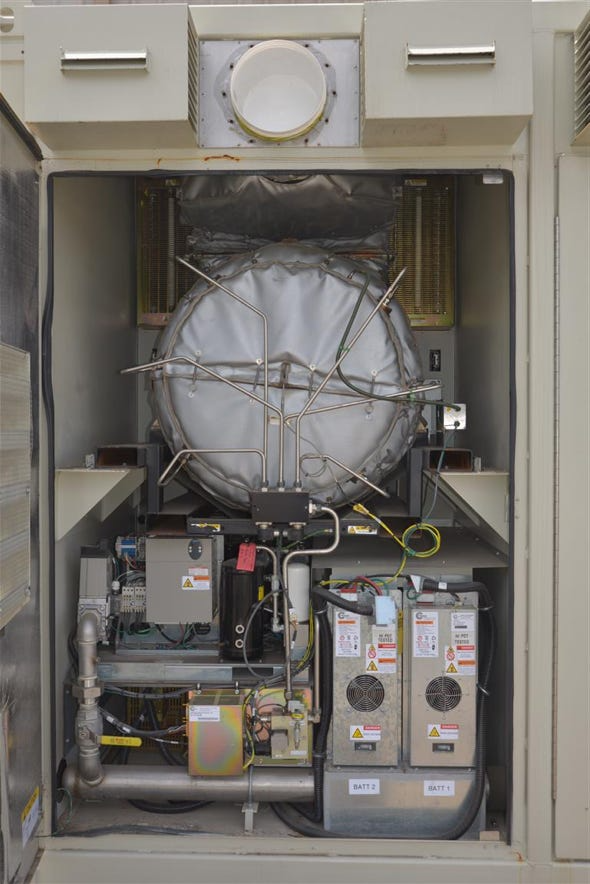

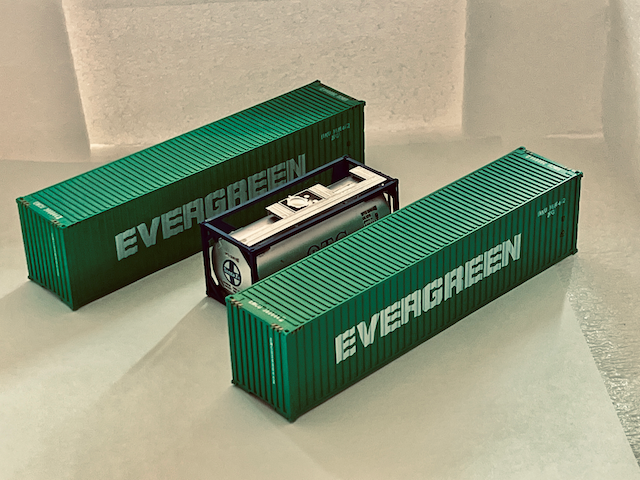

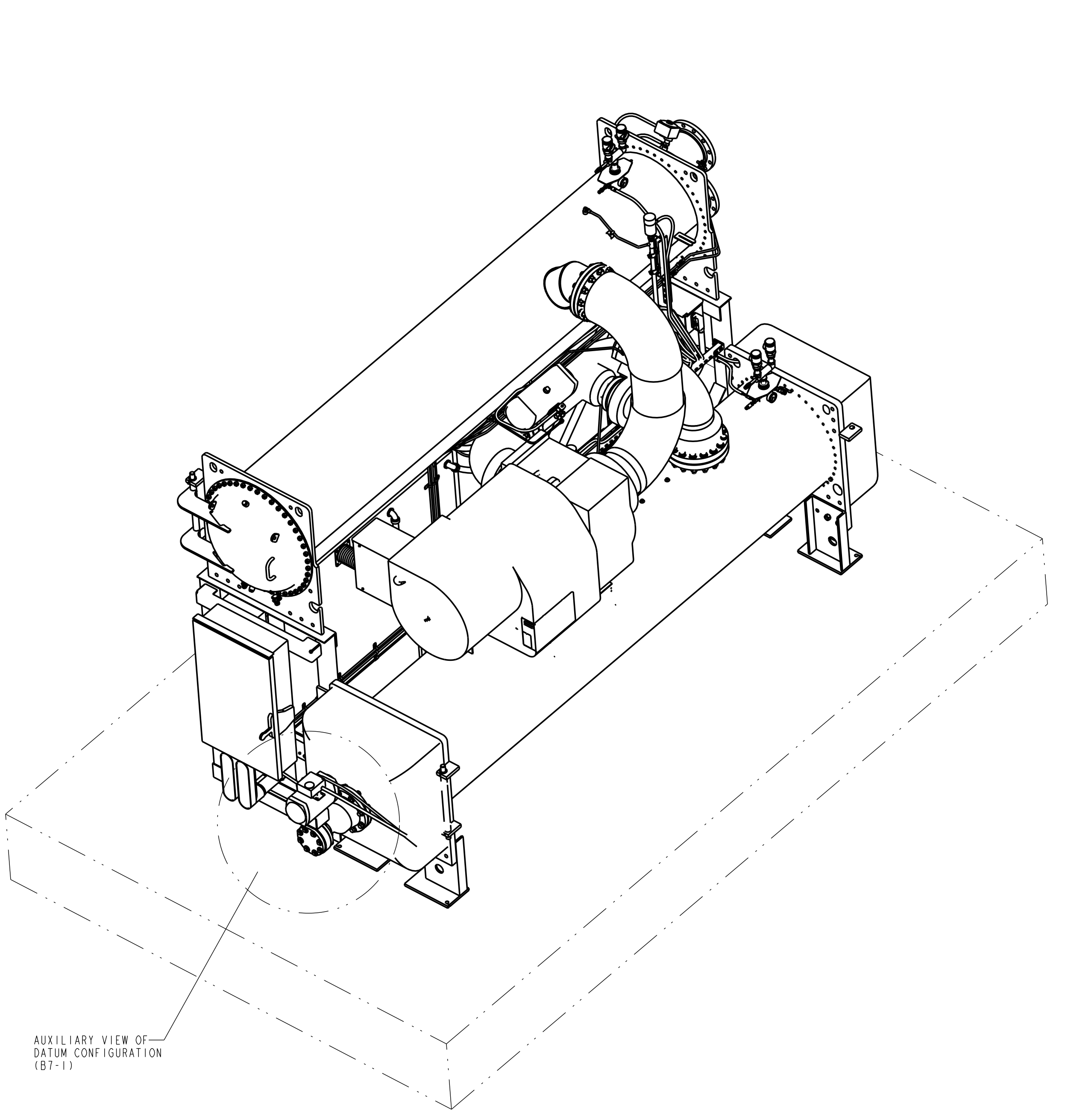

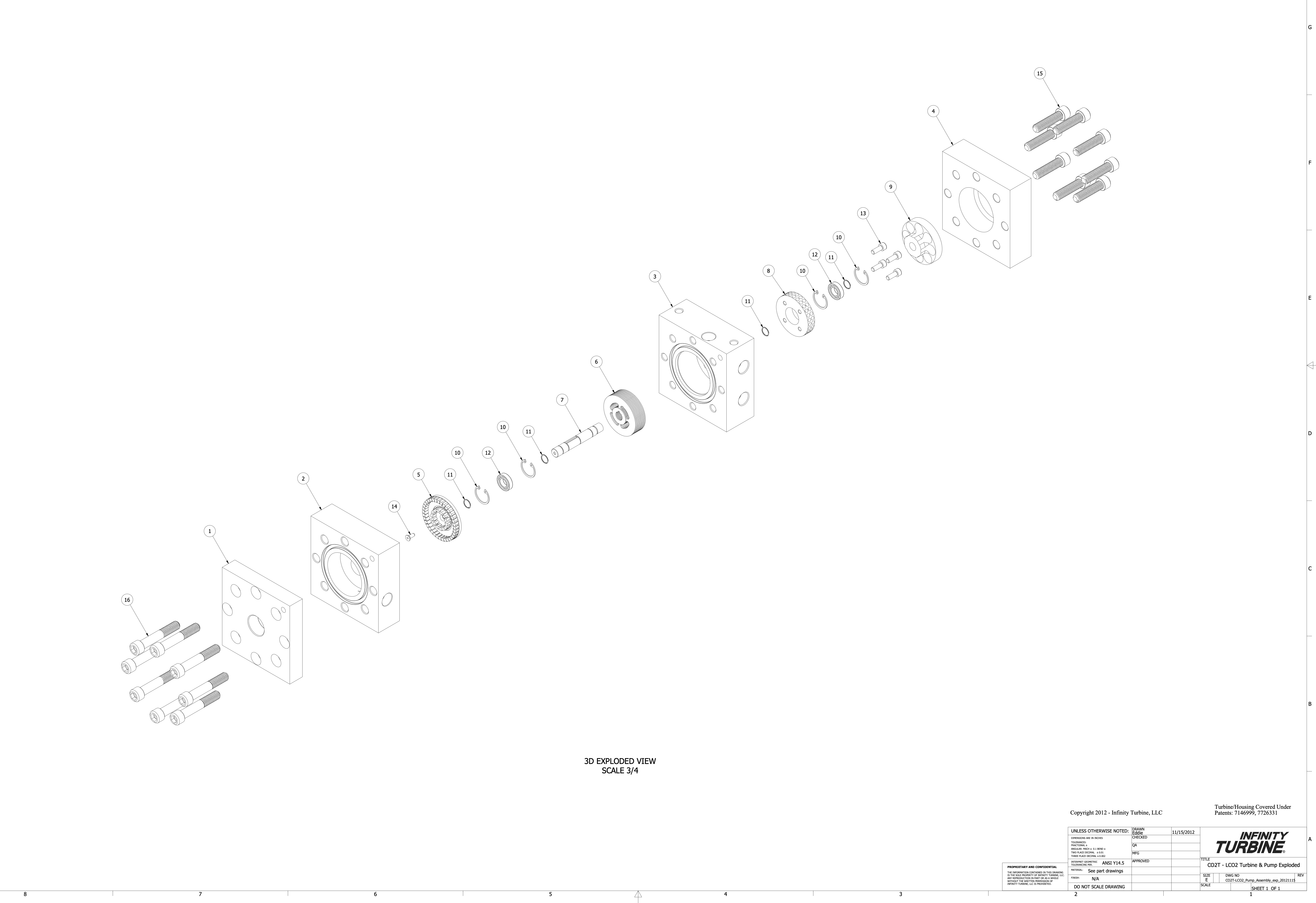

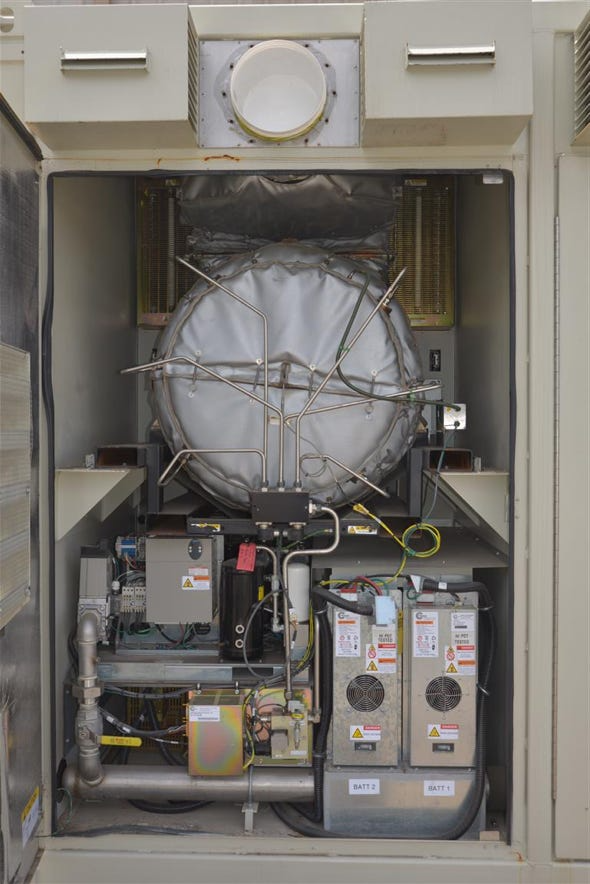

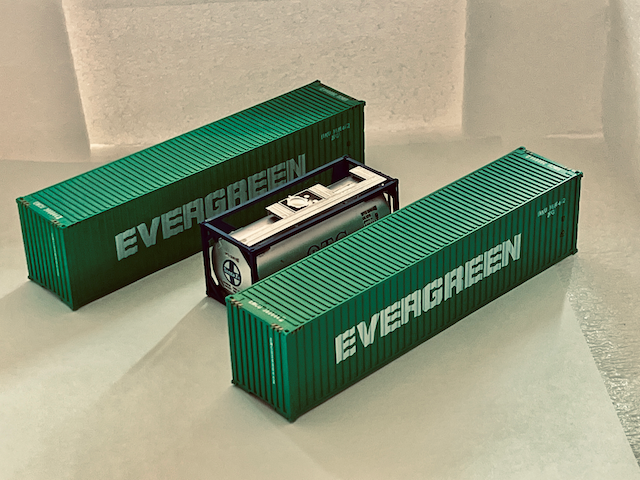

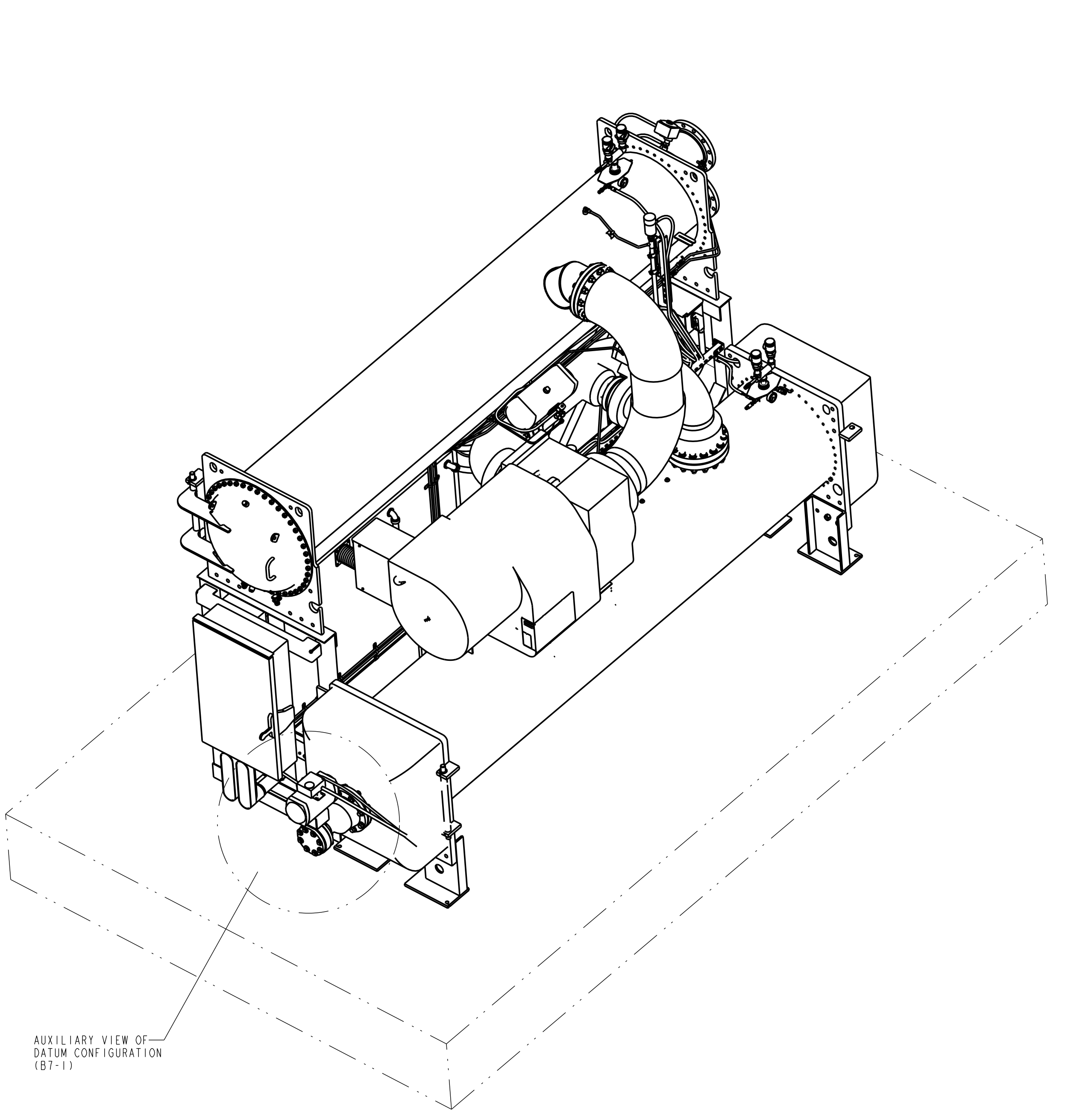

The beauty of the flow battery system is its simplicity. The costs of a factory setup will depend on the production desired (both size and quantity of batteries produced per year).The main production-line fabrication will be the electrolyzer blades. All other components may be purchased off-the-shelf or outsourced.Factory Setup: Large Components: Shipping containers. Recommend outsourcing. Can assemble at facility. Alternative is to ship electrolyzer, then set up large liquid tanks at the point of use.Infrastructure and Control: Piping, valves, and pumps with controller (wiring and sensors). Note: Adaptor kits can be produced to make this fabrication modular (connection of tanks to piping and pumps).Electrolyzer Blade Unit (the heart of the system): 1. Assembly housing which contains (liquid tight, non-pressurized, anode, cathode)The assembly housing could be made out of plastic as long as it's tolerant to Chlorine, or can be made in blade format (similar to computer servers) using brake press to bend metal sheets. 2. Electrolyzers can be plug-in within that assembly. (a) Anode: Purchased off-the-shelf or made in-house using metal and coating. (b) Cathode: There are a variety of methods to fabricate the cathode. The cathode can be made in a variety of formats depending on application and end-use (only battery, desalination, producing graphene). The cathode material and composition will be determined on end-use. Most formats will need mixing powders with associated heat and pressing applications that can easily be automated using existing machinery. The shape, composition, and amount are proprietary and provided with the license once purchased.3. Labor: To install above.4. Kits: Alternative for full battery system is to provide sale of electrolyzer (blades) and have customer do installation at point of use.

|

|

|

|

|

Introduction

Grid-scale batteries are an essential component of our modern energy infrastructure, and their production has become a critical factor in our ability to transition to a clean energy future. As demand for grid-scale batteries continues to grow, the manufacturing process has become a key area of focus for companies in the energy sector. In this article, we will explore the on-demand factory model and the Tesla Gigafactory format for grid-scale battery manufacturing, and compare their advantages and disadvantages, as well as their impact on production efficiency, scalability, and cost-effectiveness for the production of a Tesla Megapack and a grid-scale flow battery.

|

|

|

|

|

Defining the on-demand factory model and Tesla Gigafactory format

The on-demand factory model is a flexible manufacturing process that can be built within a year and can be easily scaled up or down as needed. This approach is designed to meet the changing demands of the market and enable manufacturers to adjust their production output to match market needs. On the other hand, the Tesla Gigafactory format is a massive manufacturing facility that is optimized for large-scale production. This model is designed to achieve economies of scale, increase production efficiency, and drive down costs.

|

|

|

|

|

Production efficiency

When it comes to production efficiency, the Tesla Gigafactory format has a clear advantage due to its economies of scale. The factory can produce a high volume of batteries quickly and efficiently, with a streamlined production process and cutting-edge automation technology. However, the on-demand factory model offers greater flexibility, which can be an advantage in certain situations. For example, if a manufacturer needs to produce a smaller volume of batteries with a higher degree of customization, an on-demand factory may be a more efficient option.

|

|

|

|

|

Scalability

One of the primary advantages of the on-demand factory model is its scalability. The ability to easily adjust production output to match changing market demands can be a significant advantage, especially in a fast-moving market like the energy sector. On the other hand, the Tesla Gigafactory format is optimized for large-scale production, which can be a disadvantage if demand for batteries decreases or if the market shifts towards smaller-scale production.

|

|

|

|

|

Cost-effectiveness

The cost-effectiveness of the two manufacturing models depends on several factors, including the volume of batteries produced, the level of customization required, and the overall demand for batteries. In general, the Tesla Gigafactory format is more cost-effective for high-volume production, thanks to its economies of scale. However, the on-demand factory model can be more cost-effective in situations where smaller volumes of batteries are needed or when a higher degree of customization is required.

|

|

|

|

|

Production of Tesla Megapack and grid-scale flow battery

When it comes to the production of a Tesla Megapack and a grid-scale flow battery, both the on-demand factory model and the Tesla Gigafactory format have their advantages and disadvantages. The Tesla Gigafactory format is well-suited for the high-volume production of standardized batteries, while the on-demand factory model may be a better option for producing smaller volumes of batteries with a higher degree of customization.

|

|

|

|

|

Conclusion

In conclusion, the on-demand factory model and the Tesla Gigafactory format offer distinct advantages and disadvantages for grid-scale battery production. The choice of manufacturing model ultimately depends on a variety of factors, including production efficiency, scalability, and cost-effectiveness. As the demand for grid-scale batteries continues to grow, manufacturers will need to carefully consider their manufacturing options to ensure they can meet the changing demands of the market.

|