Salgenx LLC • Design • Develop • Analysis TEL: 1-608-238-6001 Email: greg@salgenx.com

3 MWh Grid Scale Saltwater Flow Battery that is Self Healing

|

|

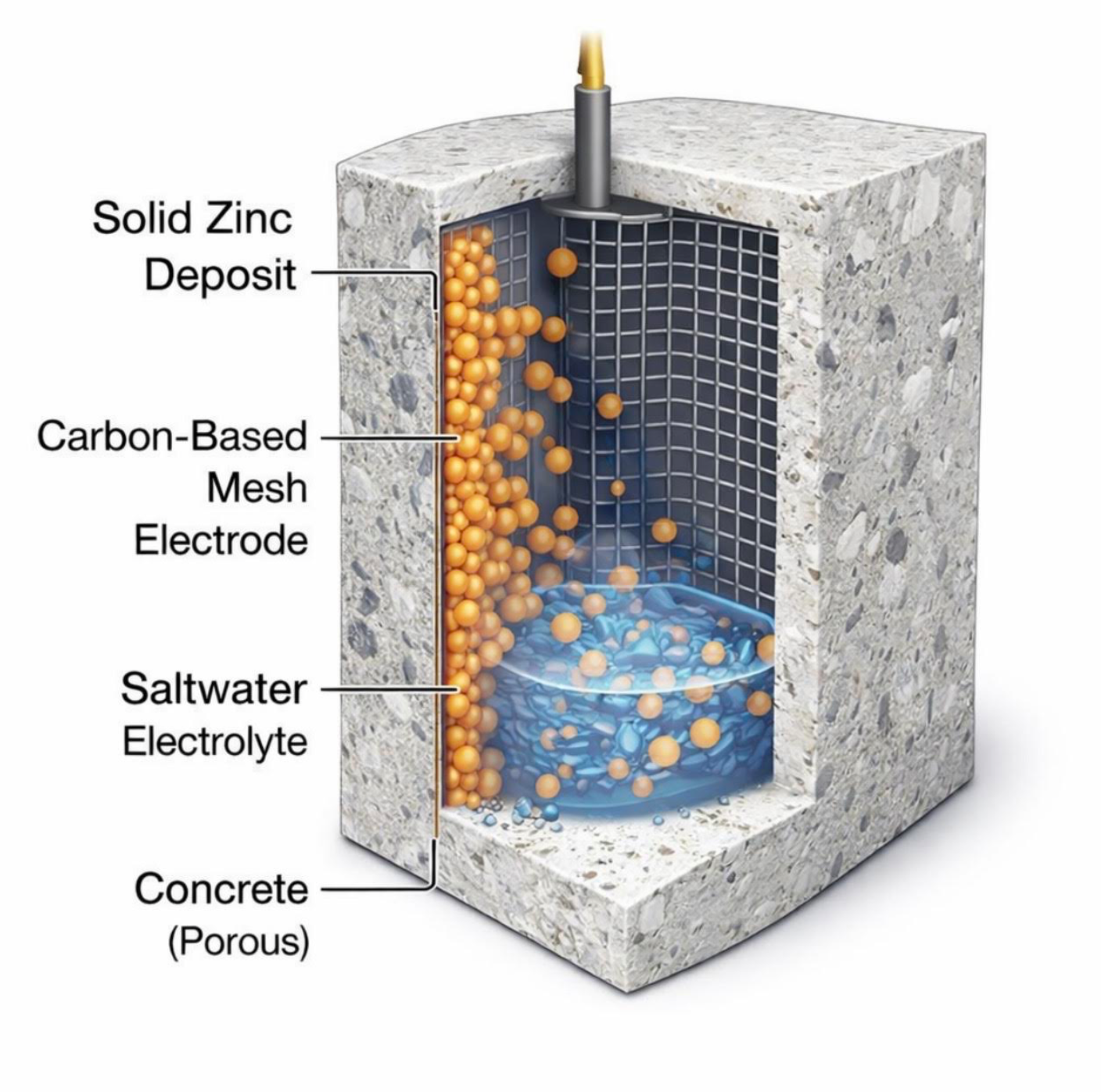

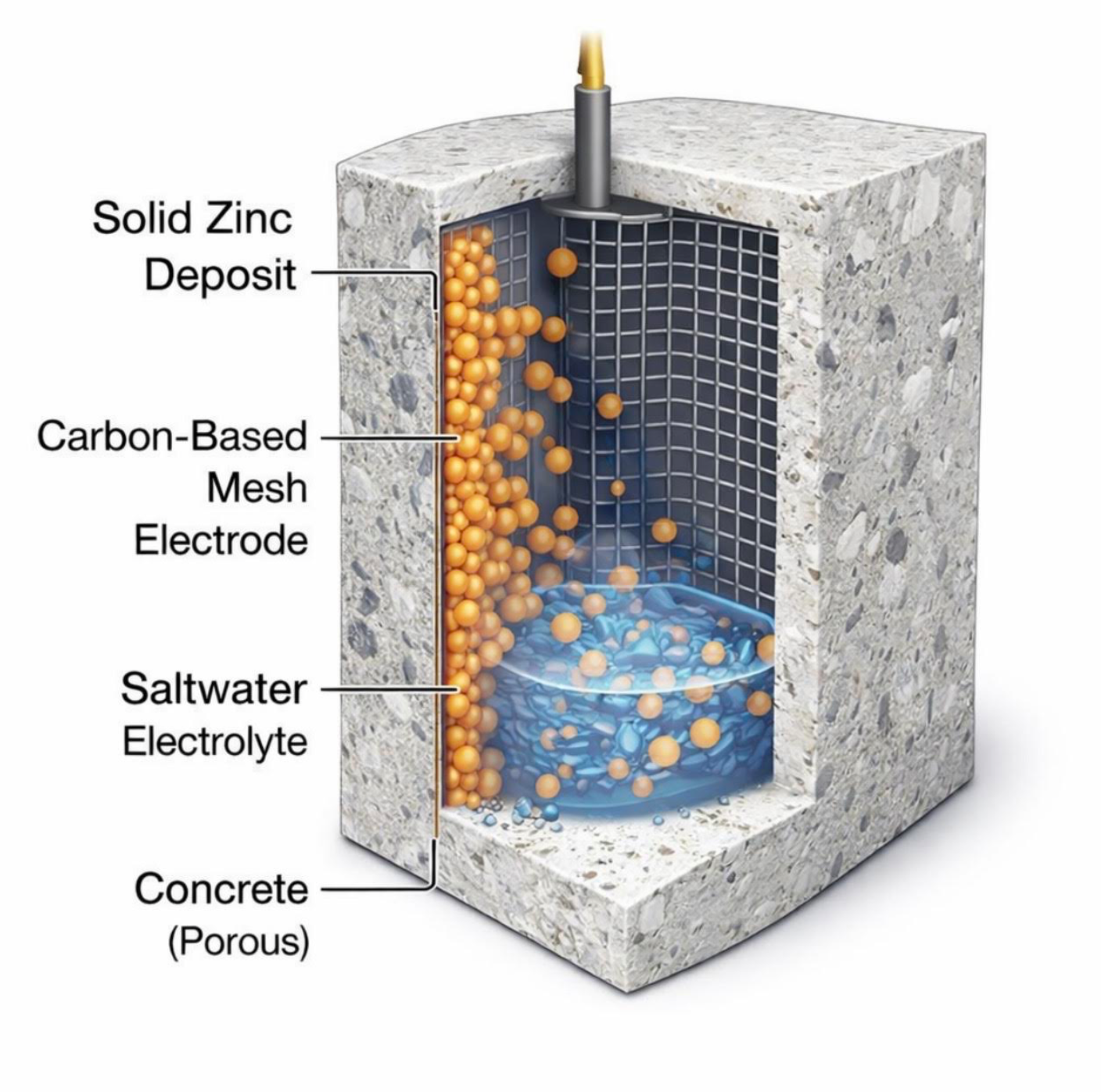

Integrating Concrete Electrochemical Structures with Membrane Free Saltwater Flow Batteries Concrete is no longer just a structural material. When engineered with controlled porosity and embedded conductive networks, it can function as an electrochemical medium that stores energy, stabilizes ion transport, and suppresses dendrite growth. This article explains how concrete can be integrated with membrane free saltwater flow batteries, how ions move through cement structures, and how performance compares to conventional flow battery designs.Large scale stationary energy storage is rapidly evolving toward systems that combine structural mass, electrochemical storage, and thermal buffering into unified infrastructure. Saltwater flow batteries already operate at scales where civil construction dominates cost and footprint. Concrete, which forms the structural backbone of most industrial installations, can be engineered to participate directly in energy storage rather than remain passive.This article explains how concrete can function as an ionic transport medium, how embedded electrode mesh enables electrochemical operation inside cement structures, how zinc deposition behavior changes in porous mineral matrices, and how hybrid systems compare in energy density to standard membrane free saltwater flow batteries.Saltwater Flow Batteries Without MembranesA membrane free saltwater flow battery typically consists of:• Two liquid electrolyte reservoirs• Electrochemical reaction zones• Circulating pumps• External power electronicsThe electrolytes contain dissolved ions such as sodium or zinc species. Energy is stored and released through oxidation and reduction reactions occurring at electrodes while electrolyte solutions circulate.In membrane free designs, separation between reactants is achieved through fluid control, density stratification, flow management, or spatial geometry rather than polymer membranes. This reduces cost and simplifies maintenance, but the energy storage mechanism remains entirely fluid based.Key characteristics of a standard membrane free saltwater flow battery:• Energy stored in liquid electrolyte volume• Ion transport primarily in free flowing liquid• Electrodes localized to reaction zones• High reversibility of electrochemical reactions• Very low fire risk• Long operational lifeEnergy density is determined primarily by:• concentration of active ions in solution• electrochemical potential difference• volume of electrolyteTypical energy density is relatively low compared to lithium batteries but suitable for grid scale storage.Transforming Concrete into an Electrochemical MediumConcrete naturally contains a porous internal structure filled with water and dissolved ions. When saturated, this pore network forms a continuous ionic pathway. If conductive electrodes are embedded within the material, the structure becomes a solid porous electrolyte battery.In a hybrid concrete saltwater system, concrete performs several functions simultaneously:• structural support• electrolyte containment• ion transport medium• mechanical regulator of metal deposition• distributed electrode hostTo enable this, the concrete must be engineered with:• controlled pore connectivity• stable moisture content• ionic conductivity• embedded conductive mesh or fiber networksThe result is a mineral scaffold that behaves as a diffusion limited electrochemical environment.How Ions Move Through ConcreteIon motion in concrete occurs through the liquid phase within the pore network. Transport mechanisms include:• electric field driven migration• concentration gradient diffusion• slow convection if moisture gradients existWhen a potential difference is applied between embedded electrodes, positively charged ions such as sodium or zinc migrate through interconnected pores toward the cathode.At the cathode surface, electrochemical reduction occurs. For zinc systems, ions gain electrons and deposit as solid metal. For sodium systems, ions may be stored through adsorption or host material insertion depending on chemistry.The rate of ion transport depends on:• pore size distribution• tortuosity of pathways• ionic concentration• water saturation• temperatureConcrete therefore behaves as a slower but highly stable ionic transport medium compared to free liquid electrolyte.Embedded Electrode Mesh in ConcreteTo operate electrochemically, conductive networks must be distributed throughout the concrete volume. These may include:• carbon fiber mesh• graphite felt• steel reinforcement• titanium coated conductors• conductive carbon aggregatesEmbedded mesh dramatically increases electrode surface area and distributes current density. Instead of localized plating zones, electrochemical reactions occur throughout the structure.This creates a three dimensional electrode system where the entire concrete mass participates in energy storage.Zinc Deposition Behavior in ConcreteZinc plating stability is one of the most important engineering advantages of concrete integrated systems.In liquid electrolytes, zinc often forms dendrites. These needle like structures grow from localized high current density points and can eventually cause short circuits or capacity loss.Concrete modifies plating behavior through three mechanisms:• Mechanical constraintPore walls physically limit metal growth and restrict filament formation.• Diffusion limitationIon supply is moderated by pore transport, reducing localized supersaturation.• Distributed current densityLarge electrode area lowers plating intensity at any single point.Instead of forming long dendrites, zinc tends to deposit more uniformly along pore surfaces or within conductive scaffolds. This leads to smoother, more reversible plating and longer cycle life.Structural and Thermal BenefitsConcrete provides additional system level advantages beyond electrochemistry.• High thermal mass stabilizes temperature during charge and discharge.• Mechanical rigidity contains expansion forces.• Fire resistance improves safety.• Distributed storage reduces localized stress on electrolyte chemistry.These characteristics enhance the operational stability of saltwater batteries.Energy Density ComparisonA critical question is how energy density compares between conventional membrane free saltwater flow batteries and concrete integrated systems.Energy density must be considered in two ways:• volumetric storage of active electrolyte• total system storage including structural participationStandard Membrane Free Saltwater Flow BatteryEnergy is stored entirely in liquid electrolyte.Advantages:• higher ion mobility• full electrolyte accessibility• minimal diffusion limitation• efficient electrochemical utilizationTypical effective volumetric energy density depends on electrolyte chemistry but is often in the range of roughly 10 to 40 watt hours per liter of electrolyte.Structural components do not contribute to storage.Concrete Embedded Electrode Hybrid SystemEnergy is stored in both:• liquid electrolyte• porous solid mineral structureHowever, ion mobility in concrete is slower and pore volume is smaller than free liquid. Not all pore space is electrochemically active.Effective volumetric energy density of the concrete portion alone is lower than free electrolyte storage, often several times lower depending on porosity and conductivity.But total system level energy density can increase because structural mass becomes active rather than passive.Practical ComparisonStandard membrane free saltwater flow battery:• Higher electrolyte energy density• Fast charge and discharge• Localized reaction zonesConcrete integrated system:• Lower storage per unit volume of concrete• Much larger active structural volume• Distributed storage• Enhanced stability• Reduced dendrite risk• Improved thermal bufferingWhen considering total installation footprint, hybrid systems may achieve similar or greater total energy storage per site because foundations, walls, and containment structures become active components.System Level ImplicationsConcrete integration does not replace saltwater flow battery chemistry. Instead it transforms infrastructure into an energy participating medium.Benefits include:• reduced electrochemical stress• improved charge distribution• extended cycle life• enhanced safety margins• structural multifunctionalityThe hybrid system becomes an electro thermochemical civil structure rather than a standalone battery unit.ConclusionConcrete can function as an ionic transport medium and electrochemical host when engineered with controlled porosity and embedded conductive mesh. Ions migrate through pore fluid, electrodes distributed within the structure enable redox reactions, and mechanical confinement stabilizes zinc deposition by suppressing dendritic growth.Compared to standard membrane free saltwater flow batteries, concrete integrated systems have lower local energy density but potentially greater total system storage because structural mass becomes electrochemically active. The hybrid approach provides enhanced stability, distributed storage, and long term durability.As energy storage scales continue to grow, the most efficient designs will not treat civil infrastructure as passive support. Instead, foundations, containment, and structural materials will increasingly participate directly in storing and managing energy. |

| CONTACT TEL: +1 608-238-6001 (Chicago Time Zone) Email: greg@salgenx.com | AMP | PDF | Salgenx is a division of Infinity Turbine LLC |