PDF Publication Title:

Text from PDF Page: 003

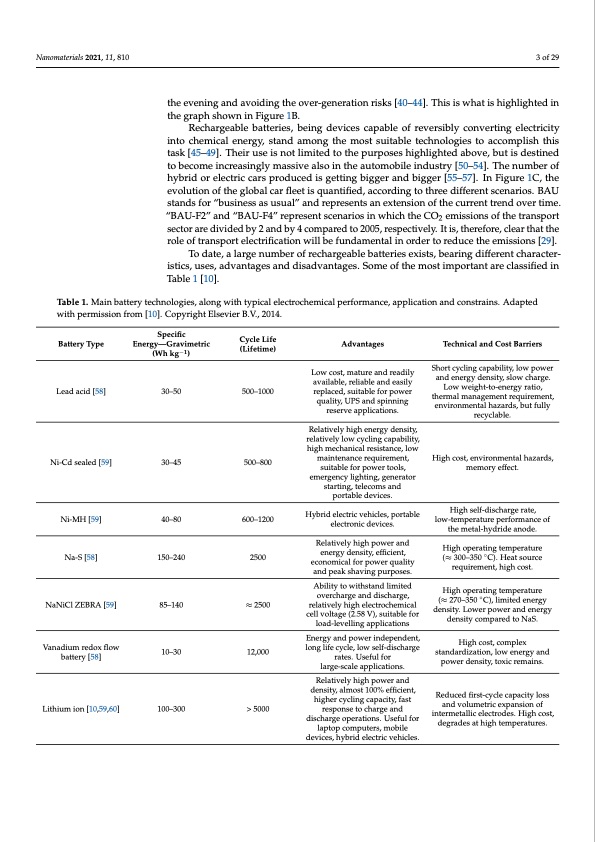

Nanomaterials 2021, 11, 810 3 of 29 the evening and avoiding the over-generation risks [40–44]. This is what is highlighted in the graph shown in Figure 1B. Rechargeable batteries, being devices capable of reversibly converting electricity into chemical energy, stand among the most suitable technologies to accomplish this task [45–49]. Their use is not limited to the purposes highlighted above, but is destined to become increasingly massive also in the automobile industry [50–54]. The number of hybrid or electric cars produced is getting bigger and bigger [55–57]. In Figure 1C, the evolution of the global car fleet is quantified, according to three different scenarios. BAU stands for “business as usual” and represents an extension of the current trend over time. “BAU-F2” and “BAU-F4” represent scenarios in which the CO2 emissions of the transport sector are divided by 2 and by 4 compared to 2005, respectively. It is, therefore, clear that the role of transport electrification will be fundamental in order to reduce the emissions [29]. To date, a large number of rechargeable batteries exists, bearing different character- istics, uses, advantages and disadvantages. Some of the most important are classified in Table 1 [10]. Table 1. Main battery technologies, along with typical electrochemical performance, application and constrains. Adapted with permission from [10]. Copyright Elsevier B.V., 2014. Battery Type Lead acid [58] Ni-Cd sealed [59] Ni-MH [59] Na-S [58] NaNiCl ZEBRA [59] Vanadium redox flow battery [58] Lithium ion [10,59,60] Specific Energy—Gravimetric (Wh kg−1) 30–50 30–45 40–80 150–240 85–140 10–30 100–300 Cycle Life (Lifetime) 500–1000 500–800 600–1200 2500 ≈ 2500 12,000 > 5000 Advantages Low cost, mature and readily available, reliable and easily replaced, suitable for power quality, UPS and spinning reserve applications. Relatively high energy density, relatively low cycling capability, high mechanical resistance, low maintenance requirement, suitable for power tools, emergency lighting, generator starting, telecoms and portable devices. Hybrid electric vehicles, portable electronic devices. Relatively high power and energy density, efficient, economical for power quality and peak shaving purposes. Ability to withstand limited overcharge and discharge, relatively high electrochemical cell voltage (2.58 V), suitable for load-levelling applications Energy and power independent, long life cycle, low self-discharge rates. Useful for large-scale applications. Relatively high power and density, almost 100% efficient, higher cycling capacity, fast response to charge and discharge operations. Useful for laptop computers, mobile devices, hybrid electric vehicles. Technical and Cost Barriers Short cycling capability, low power and energy density, slow charge. Low weight-to-energy ratio, thermal management requirement, environmental hazards, but fully recyclable. High cost, environmental hazards, memory effect. High self-discharge rate, low-temperature performance of the metal-hydride anode. High operating temperature (≈ 300–350 ◦C). Heat source requirement, high cost. High operating temperature (≈ 270–350 ◦C), limited energy density. Lower power and energy density compared to NaS. High cost, complex standardization, low energy and power density, toxic remains. Reduced first-cycle capacity loss and volumetric expansion of intermetallic electrodes. High cost, degrades at high temperatures.PDF Image | Overview on Anodes for Magnesium Batteries

PDF Search Title:

Overview on Anodes for Magnesium BatteriesOriginal File Name Searched:

nanomaterials-11-00810.pdfDIY PDF Search: Google It | Yahoo | Bing

Product and Development Focus for Salgenx

Redox Flow Battery Technology: With the advent of the new USA tax credits for producing and selling batteries ($35/kW) we are focussing on a simple flow battery using shipping containers as the modular electrolyte storage units with tax credits up to $140,000 per system. Our main focus is on the salt battery. This battery can be used for both thermal and electrical storage applications. We call it the Cogeneration Battery or Cogen Battery. One project is converting salt (brine) based water conditioners to simultaneously produce power. In addition, there are many opportunities to extract Lithium from brine (salt lakes, groundwater, and producer water).Salt water or brine are huge sources for lithium. Most of the worlds lithium is acquired from a brine source. It's even in seawater in a low concentration. Brine is also a byproduct of huge powerplants, which can now use that as an electrolyte and a huge flow battery (which allows storage at the source).We welcome any business and equipment inquiries, as well as licensing our flow battery manufacturing.| CONTACT TEL: 608-238-6001 Email: greg@salgenx.com | RSS | AMP |