PDF Publication Title:

Text from PDF Page: 006

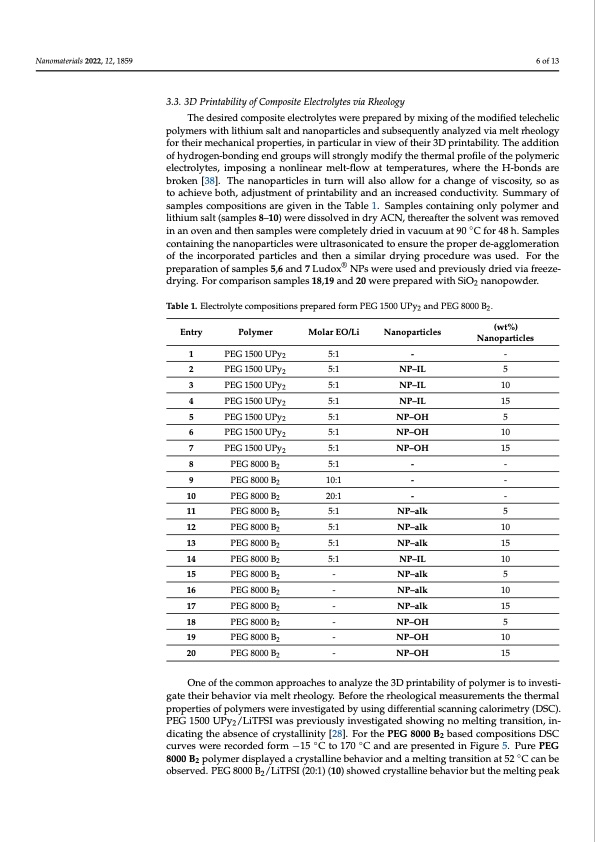

Nanomaterials 2022, 12, 1859 6 of 13 3.3. 3D Printability of Composite Electrolytes via Rheology The desired composite electrolytes were prepared by mixing of the modified telechelic polymers with lithium salt and nanoparticles and subsequently analyzed via melt rheology for their mechanical properties, in particular in view of their 3D printability. The addition of hydrogen-bonding end groups will strongly modify the thermal profile of the polymeric electrolytes, imposing a nonlinear melt-flow at temperatures, where the H-bonds are broken [38]. The nanoparticles in turn will also allow for a change of viscosity, so as to achieve both, adjustment of printability and an increased conductivity. Summary of samples compositions are given in the Table 1. Samples containing only polymer and lithium salt (samples 8–10) were dissolved in dry ACN, thereafter the solvent was removed in an oven and then samples were completely dried in vacuum at 90 ◦C for 48 h. Samples containing the nanoparticles were ultrasonicated to ensure the proper de-agglomeration of the incorporated particles and then a similar drying procedure was used. For the preparation of samples 5,6 and 7 Ludox® NPs were used and previously dried via freeze- drying. For comparison samples 18,19 and 20 were prepared with SiO2 nanopowder. Table 1. Electrolyte compositions prepared form PEG 1500 UPy2 and PEG 8000 B2. Entry 1 PEG 1500 UPy2 2 PEG 1500 UPy2 3 PEG 1500 UPy2 4 PEG 1500 UPy2 5 PEG 1500 UPy2 6 PEG 1500 UPy2 7 PEG 1500 UPy2 8 PEG 8000 B2 9 PEG 8000 B2 10 PEG 8000 B2 11 PEG 8000 B2 12 PEG 8000 B2 13 PEG 8000 B2 14 PEG 8000 B2 15 PEG 8000 B2 16 PEG 8000 B2 17 PEG 8000 B2 18 PEG 8000 B2 19 PEG 8000 B2 20 PEG 8000 B2 Molar EO/Li 5:1 5:1 5:1 5:1 5:1 5:1 5:1 5:1 10:1 20:1 5:1 5:1 5:1 5:1 - - - - - - (wt%) Nanoparticles Polymer Nanoparticles -- NP–IL 5 NP–IL 10 NP–IL 15 NP–OH 5 NP–OH 10 NP–OH 15 - - - - - - NP–alk 5 NP–alk 10 NP–alk 15 NP–IL 10 NP–alk 5 NP–alk 10 NP–alk 15 NP–OH 5 NP–OH 10 NP–OH 15 One of the common approaches to analyze the 3D printability of polymer is to investi- gate their behavior via melt rheology. Before the rheological measurements the thermal properties of polymers were investigated by using differential scanning calorimetry (DSC). PEG 1500 UPy2/LiTFSI was previously investigated showing no melting transition, in- dicating the absence of crystallinity [28]. For the PEG 8000 B2 based compositions DSC curves were recorded form −15 ◦C to 170 ◦C and are presented in Figure 5. Pure PEG 8000 B2 polymer displayed a crystalline behavior and a melting transition at 52 ◦C can be observed. PEG 8000 B2/LiTFSI (20:1) (10) showed crystalline behavior but the melting peakPDF Image | 3D Printable Composite Polymer Electrolytes

PDF Search Title:

3D Printable Composite Polymer ElectrolytesOriginal File Name Searched:

nanomaterials-12-01859-v2.pdfDIY PDF Search: Google It | Yahoo | Bing

Product and Development Focus for Salgenx

Redox Flow Battery Technology: With the advent of the new USA tax credits for producing and selling batteries ($35/kW) we are focussing on a simple flow battery using shipping containers as the modular electrolyte storage units with tax credits up to $140,000 per system. Our main focus is on the salt battery. This battery can be used for both thermal and electrical storage applications. We call it the Cogeneration Battery or Cogen Battery. One project is converting salt (brine) based water conditioners to simultaneously produce power. In addition, there are many opportunities to extract Lithium from brine (salt lakes, groundwater, and producer water).Salt water or brine are huge sources for lithium. Most of the worlds lithium is acquired from a brine source. It's even in seawater in a low concentration. Brine is also a byproduct of huge powerplants, which can now use that as an electrolyte and a huge flow battery (which allows storage at the source).We welcome any business and equipment inquiries, as well as licensing our flow battery manufacturing.| CONTACT TEL: 608-238-6001 Email: greg@salgenx.com | RSS | AMP |