PDF Publication Title:

Text from PDF Page: 003

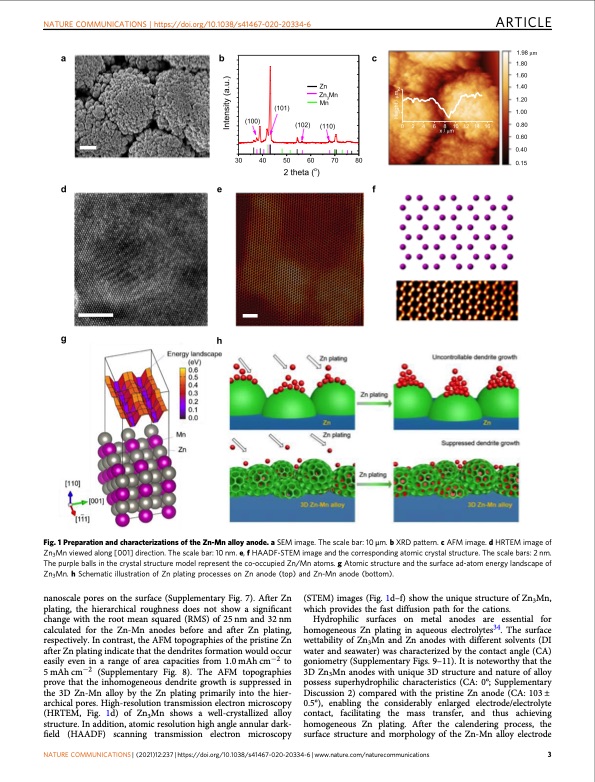

NATURE COMMUNICATIONS | https://doi.org/10.1038/s41467-020-20334-6 ARTICLE Fig. 1 Preparation and characterizations of the Zn-Mn alloy anode. a SEM image. The scale bar: 10 μm. b XRD pattern. c AFM image. d HRTEM image of Zn3Mn viewed along [001] direction. The scale bar: 10 nm. e, f HAADF-STEM image and the corresponding atomic crystal structure. The scale bars: 2 nm. The purple balls in the crystal structure model represent the co-occupied Zn/Mn atoms. g Atomic structure and the surface ad-atom energy landscape of Zn3Mn. h Schematic illustration of Zn plating processes on Zn anode (top) and Zn-Mn anode (bottom). nanoscale pores on the surface (Supplementary Fig. 7). After Zn plating, the hierarchical roughness does not show a significant change with the root mean squared (RMS) of 25 nm and 32 nm calculated for the Zn-Mn anodes before and after Zn plating, respectively. In contrast, the AFM topographies of the pristine Zn after Zn plating indicate that the dendrites formation would occur easily even in a range of area capacities from 1.0 mAh cm−2 to 5 mAh cm−2 (Supplementary Fig. 8). The AFM topographies prove that the inhomogeneous dendrite growth is suppressed in the 3D Zn-Mn alloy by the Zn plating primarily into the hier- archical pores. High-resolution transmission electron microscopy (HRTEM, Fig. 1d) of Zn3Mn shows a well-crystallized alloy structure. In addition, atomic resolution high angle annular dark- field (HAADF) scanning transmission electron microscopy (STEM) images (Fig. 1d–f) show the unique structure of Zn3Mn, which provides the fast diffusion path for the cations. Hydrophilic surfaces on metal anodes are essential for homogeneous Zn plating in aqueous electrolytes34. The surface wettability of Zn3Mn and Zn anodes with different solvents (DI water and seawater) was characterized by the contact angle (CA) goniometry (Supplementary Figs. 9–11). It is noteworthy that the 3D Zn3Mn anodes with unique 3D structure and nature of alloy possess superhydrophilic characteristics (CA: 0°; Supplementary Discussion 2) compared with the pristine Zn anode (CA: 103 ± 0.5°), enabling the considerably enlarged electrode/electrolyte contact, facilitating the mass transfer, and thus achieving homogeneous Zn plating. After the calendering process, the surface structure and morphology of the Zn-Mn alloy electrode NATURE COMMUNICATIONS | (2021)12:237 | https://doi.org/10.1038/s41467-020-20334-6 | www.nature.com/naturecommunications 3PDF Image | high-performance dendrite-free seawater-based batteries

PDF Search Title:

high-performance dendrite-free seawater-based batteriesOriginal File Name Searched:

s41467-020-20334-6.pdfDIY PDF Search: Google It | Yahoo | Bing

Product and Development Focus for Salgenx

Redox Flow Battery Technology: With the advent of the new USA tax credits for producing and selling batteries ($35/kW) we are focussing on a simple flow battery using shipping containers as the modular electrolyte storage units with tax credits up to $140,000 per system. Our main focus is on the salt battery. This battery can be used for both thermal and electrical storage applications. We call it the Cogeneration Battery or Cogen Battery. One project is converting salt (brine) based water conditioners to simultaneously produce power. In addition, there are many opportunities to extract Lithium from brine (salt lakes, groundwater, and producer water).Salt water or brine are huge sources for lithium. Most of the worlds lithium is acquired from a brine source. It's even in seawater in a low concentration. Brine is also a byproduct of huge powerplants, which can now use that as an electrolyte and a huge flow battery (which allows storage at the source).We welcome any business and equipment inquiries, as well as licensing our flow battery manufacturing.| CONTACT TEL: 608-238-6001 Email: greg@salgenx.com | RSS | AMP |