PDF Publication Title:

Text from PDF Page: 003

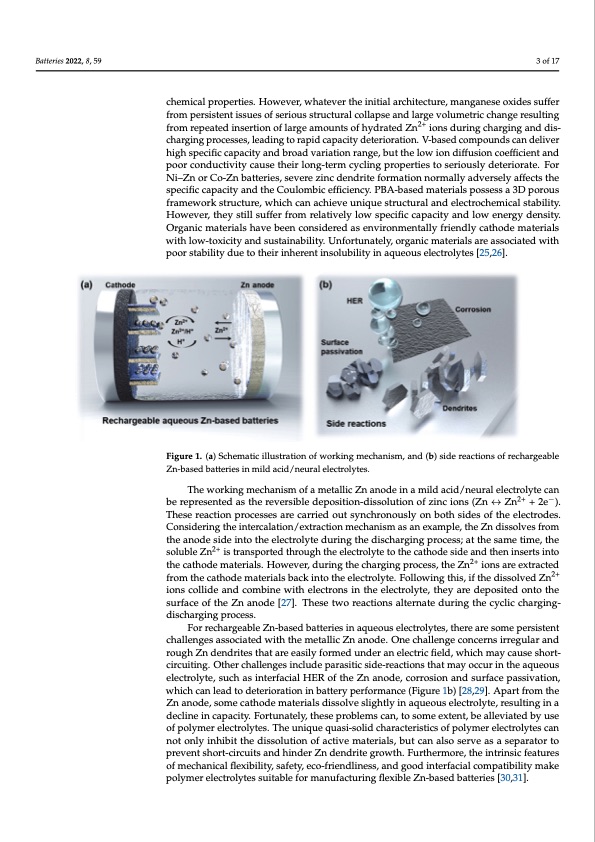

Batteries 2022, 8, x FOR PEER REVIEW 3 of 17 Batteries 2022, 8, 59 3 of 17 morphology, and phases, manganese oxides (i.e., MnO2, Mn2O3) display various electro- chemical properties. However, whatever the initial architecture, manganese oxides suffer chemical properties. However, whatever the initial architecture, manganese oxides suffer from persistent issues of serious structural collapse and large volumetric change resulting from persistent issues of serious structural collapse and large volumetric change resulting from repeated insertion of large amounts of hydrated Zn2+ ions during charging and dis- from repeated insertion of large amounts of hydrated Zn2+ ions during charging and dis- charging processes, leading to rapid capacity deterioration. V-based compounds can de- charging processes, leading to rapid capacity deterioration. V-based compounds can deliver liver high specific capacity and broad variation range, but the low ion diffusion coefficient high specific capacity and broad variation range, but the low ion diffusion coefficient and and poor conductivity cause their long-term cycling properties to seriously deteriorate. poor conductivity cause their long-term cycling properties to seriously deteriorate. For For Ni–Zn or Co-Zn batteries, severe zinc dendrite formation normally adversely affects Ni–Zn or Co-Zn batteries, severe zinc dendrite formation normally adversely affects the stphecsipfieccciafipcaccaiptyacaintydatnhde CthoeuCloomubloicmebfificceieffniciye.nPcByA. P-bBaAs-ebdamseadtemriatlesrpiaolsspeosssaes3sDap3oDropuos- froaumsefwraomrkewstorrukctsutrue,ctwuhreic,hwchainchacahnieavcehuienviqeuensiqtruectsutruacltaunrdalealnecdtreolechctermocihcaelmsitcaablilsitay-. Hbioliwtye.vHeor,wtheveyers,tihlleysusftfiellrsfurfofmer frreolamtivrellaytilvoewlyslpowecisfipceciafpicacaitpyacaintydalnodwloenweergnyerdgeyndseitny-. Osirtgy.anOircgmanaitcermialtserhiavlsehbaeveenbceoensicdoenrseidearsedenavsireonnvmiroenmtalelnytafrlileynfdrileyncdaltyhcoadtehomdaetemriaatles- wriiatlhslwowith-toloxwic-itoyxaicnidtysaunstdaisnuasbtailiintya.bUilintyfo.rUtunnfoartetulyn,aotreglya,noicrgmaantiecrmiaalstearriealassasroeciastseodciwatiethd pwoiothr sptoaboirlisttyabdiulietytodtuheetiroitnhheeireinthienrseonltuibnisloitlyuibnilaitqyuienoauqsueeloecutsroelyetcetsro[l2y5t,e2s6][.25,26]. Figure 1. (a) Schematic illustration of working mechanism, and (b) side reactions of rechargeable Figure 1. (a) Schematic illustration of working mechanism, and (b) side reactions of rechargeable Zn-based batteries in mild acid/neural electrolytes. Zn-based batteries in mild acid/neural electrolytes. The working mechanism of a metallic Zn anode in a mild acid/neural electrolyte can The working mechanism of a metallic Zn anode in a mild acid/neural electrolyte can be represented as the reversible deposition-dissolution of zinc ions (Zn ↔ Zn2+ + 2e−). be represented as the reversible deposition-dissolution of zinc ions (Zn ↔ Zn2+ + 2e−). These reaction processes are carried out synchronously on both sides of the electrodes. These reaction processes are carried out synchronously on both sides of the electrodes. Considering the intercalation/extraction mechanism as an example, the Zn dissolves from Considering the intercalation/extraction mechanism as an example, the Zn dissolves from the anode side into the electrolyte during the discharging process; at the same time, the the anode side into the electrolyte during the discharging process; at the same time, the soluble Zn2+ is transported through the electrolyte to the cathode side and then inserts into soluble Zn2+ is transported through the electrolyte to the cathode side and then inserts into the cathode materials. However, during the charging process, the Zn2+ ions are extracted the cathode materials. However, during the charging process, the Zn2+ ions are extracted from the cathode materials back into the electrolyte. Following this, if the dissolved Zn2+ from the cathode materials back into the electrolyte. Following this, if the dissolved Zn2+ ions collide and combine with electrons in the electrolyte, they are deposited onto the ions collide and combine with electrons in the electrolyte, they are deposited onto the surface of the Zn anode [27]. These two reactions alternate during the cyclic charging- surface of the Zn anode [27]. These two reactions alternate during the cyclic charging- discharging process. discharging process. For rechargeable Zn-based batteries in aqueous electrolytes, there are some persistent For rechargeable Zn-based batteries in aqueous electrolytes, there are some persistent challenges associated with the metallic Zn anode. One challenge concerns irregular and challenges associated with the metallic Zn anode. One challenge concerns irregular and rough Zn dendrites that are easily formed under an electric field, which may cause short- rough Zn dendrites that are easily formed under an electric field, which may cause short- circuiting. Other challenges include parasitic side-reactions that may occur in the aqueous circuiting. Other challenges include parasitic side-reactions that may occur in the aqueous electrolyte, such as interfacial HER of the Zn anode, corrosion and surface passivation, electrolyte, such as interfacial HER of the Zn anode, corrosion and surface passivation, which can lead to deterioration in battery performance (Figure 1b) [28,29]. Apart from the which can lead to deterioration in battery performance (Figure 1b) [28,29]. Apart from the Zn anode, some cathode materials dissolve slightly in aqueous electrolyte, resulting in a Zn anode, some cathode materials dissolve slightly in aqueous electrolyte, resulting in a decline in capacity. Fortunately, these problems can, to some extent, be alleviated by use decline in capacity. Fortunately, these problems can, to some extent, be alleviated by use of polymer electrolytes. The unique quasi-solid characteristics of polymer electrolytes can of polymer electrolytes. The unique quasi-solid characteristics of polymer electrolytes can not only inhibit the dissolution of active materials, but can also serve as a separator to not only inhibit the dissolution of active materials, but can also serve as a separator to prevent short-circuits and hinder Zn dendrite growth. Furthermore, the intrinsic features prevent short-circuits and hinder Zn dendrite growth. Furthermore, the intrinsic features of mechanical flexibility, safety, eco-friendliness, and good interfacial compatibility make polymer electrolytes suitable for manufacturing flexible Zn-based batteries [30,31].PDF Image | Flexible Zn-Based Batteries with Polymer Electrolyte

PDF Search Title:

Flexible Zn-Based Batteries with Polymer ElectrolyteOriginal File Name Searched:

batteries-08-00059.pdfDIY PDF Search: Google It | Yahoo | Bing

Product and Development Focus for Salgenx

Redox Flow Battery Technology: With the advent of the new USA tax credits for producing and selling batteries ($35/kW) we are focussing on a simple flow battery using shipping containers as the modular electrolyte storage units with tax credits up to $140,000 per system. Our main focus is on the salt battery. This battery can be used for both thermal and electrical storage applications. We call it the Cogeneration Battery or Cogen Battery. One project is converting salt (brine) based water conditioners to simultaneously produce power. In addition, there are many opportunities to extract Lithium from brine (salt lakes, groundwater, and producer water).Salt water or brine are huge sources for lithium. Most of the worlds lithium is acquired from a brine source. It's even in seawater in a low concentration. Brine is also a byproduct of huge powerplants, which can now use that as an electrolyte and a huge flow battery (which allows storage at the source).We welcome any business and equipment inquiries, as well as licensing our flow battery manufacturing.| CONTACT TEL: 608-238-6001 Email: greg@salgenx.com | RSS | AMP |