PDF Publication Title:

Text from PDF Page: 003

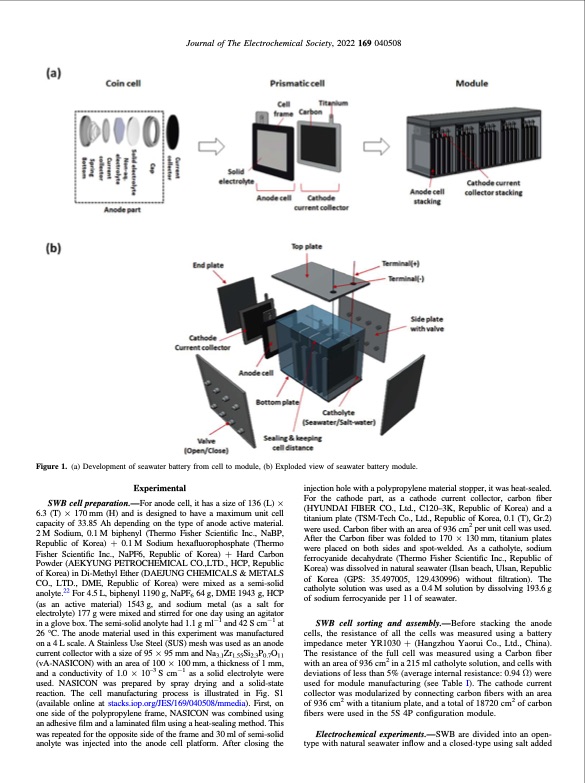

Journal of The Electrochemical Society, 2022 169 040508 Figure 1. (a) Development of seawater battery from cell to module, (b) Exploded view of seawater battery module. Experimental SWB cell preparation.—For anode cell, it has a size of 136 (L) × 6.3 (T) × 170 mm (H) and is designed to have a maximum unit cell capacity of 33.85 Ah depending on the type of anode active material. 2 M Sodium, 0.1 M biphenyl (Thermo Fisher Scientific Inc., NaBP, Republic of Korea) + 0.1 M Sodium hexafluorophosphate (Thermo Fisher Scientific Inc., NaPF6, Republic of Korea) + Hard Carbon Powder (AEKYUNG PETROCHEMICAL CO.,LTD., HCP, Republic of Korea) in Di-Methyl Ether (DAEJUNG CHEMICALS & METALS CO., LTD., DME, Republic of Korea) were mixed as a semi-solid anolyte.22 For 4.5 L, biphenyl 1190 g, NaPF6 64 g, DME 1943 g, HCP (as an active material) 1543g, and sodium metal (as a salt for electrolyte) 177 g were mixed and stirred for one day using an agitator in a glove box. The semi-solid anolyte had 1.1 g ml−1 and 42 S cm−1 at 26 °C. The anode material used in this experiment was manufactured on a 4 L scale. A Stainless Use Steel (SUS) mesh was used as an anode current collector with a size of 95 × 95 mm and Na3.1Zr1.55Si2.3P0.7O11 (vA-NASICON) with an area of 100 × 100 mm, a thickness of 1 mm, and a conductivity of 1.0 × 10–3 S cm−1 as a solid electrolyte were used. NASICON was prepared by spray drying and a solid-state reaction. The cell manufacturing process is illustrated in Fig. S1 (available online at stacks.iop.org/JES/169/040508/mmedia). First, on one side of the polypropylene frame, NASICON was combined using an adhesive film and a laminated film using a heat-sealing method. This was repeated for the opposite side of the frame and 30 ml of semi-solid anolyte was injected into the anode cell platform. After closing the injection hole with a polypropylene material stopper, it was heat-sealed. For the cathode part, as a cathode current collector, carbon fiber (HYUNDAI FIBER CO., Ltd., C120–3K, Republic of Korea) and a titanium plate (TSM-Tech Co., Ltd., Republic of Korea, 0.1 (T), Gr.2) were used. Carbon fiber with an area of 936 cm2 per unit cell was used. After the Carbon fiber was folded to 170 × 130 mm, titanium plates were placed on both sides and spot-welded. As a catholyte, sodium ferrocyanide decahydrate (Thermo Fisher Scientific Inc., Republic of Korea) was dissolved in natural seawater (Ilsan beach, Ulsan, Republic of Korea (GPS: 35.497005, 129.430996) without filtration). The catholyte solution was used as a 0.4 M solution by dissolving 193.6 g of sodium ferrocyanide per 1 l of seawater. SWB cell sorting and assembly.—Before stacking the anode cells, the resistance of all the cells was measured using a battery impedance meter YR1030 + (Hangzhou Yaorui Co., Ltd., China). The resistance of the full cell was measured using a Carbon fiber with an area of 936 cm2 in a 215 ml catholyte solution, and cells with deviations of less than 5% (average internal resistance: 0.94 Ω) were used for module manufacturing (see Table I). The cathode current collector was modularized by connecting carbon fibers with an area of 936 cm2 with a titanium plate, and a total of 18720 cm2 of carbon fibers were used in the 5S 4P configuration module. Electrochemical experiments.—SWB are divided into an open- type with natural seawater inflow and a closed-type using salt addedPDF Image | Development of Rechargeable Seawater Battery

PDF Search Title:

Development of Rechargeable Seawater BatteryOriginal File Name Searched:

Kim_2022_Electrochem-169_040508.pdfDIY PDF Search: Google It | Yahoo | Bing

Product and Development Focus for Salgenx

Redox Flow Battery Technology: With the advent of the new USA tax credits for producing and selling batteries ($35/kW) we are focussing on a simple flow battery using shipping containers as the modular electrolyte storage units with tax credits up to $140,000 per system. Our main focus is on the salt battery. This battery can be used for both thermal and electrical storage applications. We call it the Cogeneration Battery or Cogen Battery. One project is converting salt (brine) based water conditioners to simultaneously produce power. In addition, there are many opportunities to extract Lithium from brine (salt lakes, groundwater, and producer water).Salt water or brine are huge sources for lithium. Most of the worlds lithium is acquired from a brine source. It's even in seawater in a low concentration. Brine is also a byproduct of huge powerplants, which can now use that as an electrolyte and a huge flow battery (which allows storage at the source).We welcome any business and equipment inquiries, as well as licensing our flow battery manufacturing.| CONTACT TEL: 608-238-6001 Email: greg@salgenx.com | RSS | AMP |