PDF Publication Title:

Text from PDF Page: 004

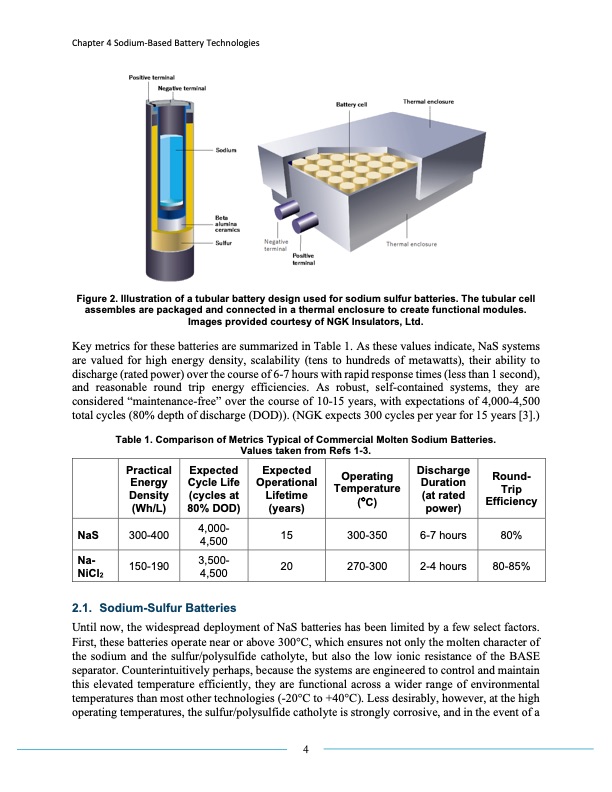

Chapter 4 Sodium-Based Battery Technologies Figure 2. Illustration of a tubular battery design used for sodium sulfur batteries. The tubular cell assembles are packaged and connected in a thermal enclosure to create functional modules. Images provided courtesy of NGK Insulators, Ltd. Key metrics for these batteries are summarized in Table 1. As these values indicate, NaS systems are valued for high energy density, scalability (tens to hundreds of metawatts), their ability to discharge (rated power) over the course of 6-7 hours with rapid response times (less than 1 second), and reasonable round trip energy efficiencies. As robust, self-contained systems, they are considered “maintenance-free” over the course of 10-15 years, with expectations of 4,000-4,500 total cycles (80% depth of discharge (DOD)). (NGK expects 300 cycles per year for 15 years [3].) Table 1. Comparison of Metrics Typical of Commercial Molten Sodium Batteries. Values taken from Refs 1-3. Practical Energy Density (Wh/L) Expected Cycle Life (cycles at 80% DOD) Expected Operational Lifetime (years) Operating Temperature (°C) Discharge Duration (at rated power) Round- Trip Efficiency NaS Na- NiCl2 300-400 150-190 4,000- 15 300-350 6-7 hours 80% 4,500 3,500- 20 270-300 2-4 hours 4,500 80-85% 2.1. Sodium-Sulfur Batteries Until now, the widespread deployment of NaS batteries has been limited by a few select factors. First, these batteries operate near or above 300°C, which ensures not only the molten character of the sodium and the sulfur/polysulfide catholyte, but also the low ionic resistance of the BASE separator. Counterintuitively perhaps, because the systems are engineered to control and maintain this elevated temperature efficiently, they are functional across a wider range of environmental temperatures than most other technologies (-20°C to +40°C). Less desirably, however, at the high operating temperatures, the sulfur/polysulfide catholyte is strongly corrosive, and in the event of a 4PDF Image | SODIUM-BASED BATTERY TECHNOLOGIES

PDF Search Title:

SODIUM-BASED BATTERY TECHNOLOGIESOriginal File Name Searched:

ESHB_Ch4_Sodium_Spoerke.pdfDIY PDF Search: Google It | Yahoo | Bing

Product and Development Focus for Salgenx

Redox Flow Battery Technology: With the advent of the new USA tax credits for producing and selling batteries ($35/kW) we are focussing on a simple flow battery using shipping containers as the modular electrolyte storage units with tax credits up to $140,000 per system. Our main focus is on the salt battery. This battery can be used for both thermal and electrical storage applications. We call it the Cogeneration Battery or Cogen Battery. One project is converting salt (brine) based water conditioners to simultaneously produce power. In addition, there are many opportunities to extract Lithium from brine (salt lakes, groundwater, and producer water).Salt water or brine are huge sources for lithium. Most of the worlds lithium is acquired from a brine source. It's even in seawater in a low concentration. Brine is also a byproduct of huge powerplants, which can now use that as an electrolyte and a huge flow battery (which allows storage at the source).We welcome any business and equipment inquiries, as well as licensing our flow battery manufacturing.| CONTACT TEL: 608-238-6001 Email: greg@salgenx.com | RSS | AMP |