PDF Publication Title:

Text from PDF Page: 002

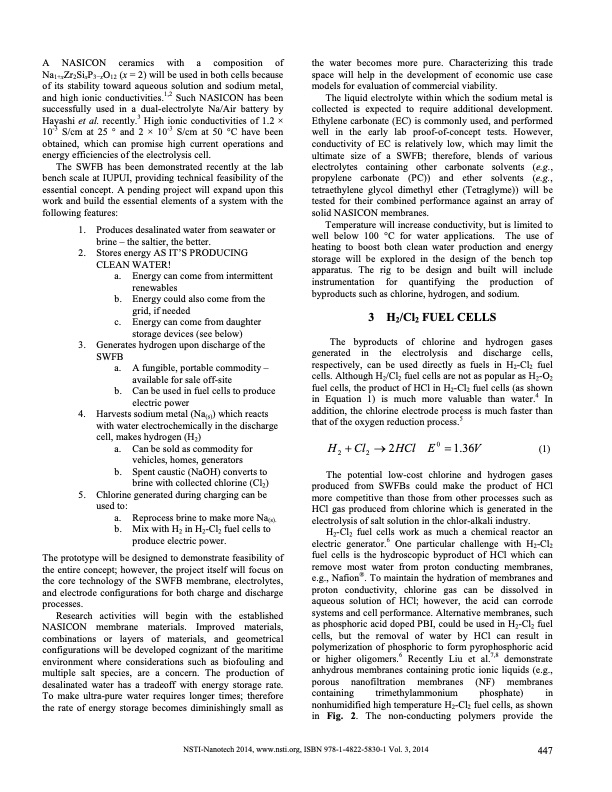

A NASICON ceramics with a composition of Na1+xZr2SixP3−xO12 (x = 2) will be used in both cells because of its stability toward aqueous solution and sodium metal, and high ionic conductivities.1,2 Such NASICON has been successfully used in a3dual-electrolyte Na/Air battery by Hayashi et al. recently. High ionic conductivities of 1.2 × 10-3 S/cmat25°and2×10-3 S/cmat50°Chavebeen obtained, which can promise high current operations and energy efficiencies of the electrolysis cell. The SWFB has been demonstrated recently at the lab bench scale at IUPUI, providing technical feasibility of the essential concept. A pending project will expand upon this work and build the essential elements of a system with the following features: 1. Produces desalinated water from seawater or brine – the saltier, the better. 2. Stores energy AS IT’S PRODUCING CLEAN WATER! a. Energy can come from intermittent renewables b. Energy could also come from the grid, if needed c. Energy can come from daughter storage devices (see below) 3. Generates hydrogen upon discharge of the SWFB a. A fungible, portable commodity – available for sale off-site b. Can be used in fuel cells to produce electric power 4. Harvests sodium metal (Na(s)) which reacts with water electrochemically in the discharge cell, makes hydrogen (H2) a. Can be sold as commodity for vehicles, homes, generators b. Spent caustic (NaOH) converts to brine with collected chlorine (Cl2) 5. Chlorine generated during charging can be used to: a. Reprocess brine to make more Na(s). b. Mix with H2 in H2-Cl2 fuel cells to produce electric power. The prototype will be designed to demonstrate feasibility of the entire concept; however, the project itself will focus on the core technology of the SWFB membrane, electrolytes, and electrode configurations for both charge and discharge processes. Research activities will begin with the established NASICON membrane materials. Improved materials, combinations or layers of materials, and geometrical configurations will be developed cognizant of the maritime environment where considerations such as biofouling and multiple salt species, are a concern. The production of desalinated water has a tradeoff with energy storage rate. To make ultra-pure water requires longer times; therefore the rate of energy storage becomes diminishingly small as the water becomes more pure. Characterizing this trade space will help in the development of economic use case models for evaluation of commercial viability. The liquid electrolyte within which the sodium metal is collected is expected to require additional development. Ethylene carbonate (EC) is commonly used, and performed well in the early lab proof-of-concept tests. However, conductivity of EC is relatively low, which may limit the ultimate size of a SWFB; therefore, blends of various electrolytes containing other carbonate solvents (e.g., propylene carbonate (PC)) and ether solvents (e.g., tetraethylene glycol dimethyl ether (Tetraglyme)) will be tested for their combined performance against an array of solid NASICON membranes. Temperature will increase conductivity, but is limited to well below 100 °C for water applications. The use of heating to boost both clean water production and energy storage will be explored in the design of the bench top apparatus. The rig to be design and built will include instrumentation for quantifying the production of byproducts such as chlorine, hydrogen, and sodium. 3 H2/Cl2 FUEL CELLS The byproducts of chlorine and hydrogen gases generated in the electrolysis and discharge cells, respectively, can be used directly as fuels in H2-Cl2 fuel cells. Although H2/Cl2 fuel cells are not as popular as H2-O2 fuel cells, the product of HCl in H2-Cl2 fuel cells (as shown in Equation 1) is much more valuable than water.4 In addition, the chlorine electrode process is much faster than that of the oxygen reduction process.5 0 H2 +Cl2 →2HCl E =1.36V (1) The potential low-cost chlorine and hydrogen gases produced from SWFBs could make the product of HCl more competitive than those from other processes such as HCl gas produced from chlorine which is generated in the electrolysis of salt solution in the chlor-alkali industry. H2-Cl2 fuel cells work as much a chemical reactor an electric generator.6 One particular challenge with H2-Cl2 fuel cells is the hydroscopic byproduct of HCl which can remove most water from proton conducting membranes, e.g., Nafion®. To maintain the hydration of membranes and proton conductivity, chlorine gas can be dissolved in aqueous solution of HCl; however, the acid can corrode systems and cell performance. Alternative membranes, such as phosphoric acid doped PBI, could be used in H2-Cl2 fuel cells, but the removal of water by HCl can result in polymerization of phosphoric to form pyrophosphoric acid or higher oligomers.6 Recently Liu et al.7,8 demonstrate anhydrous membranes containing protic ionic liquids (e.g., porous nanofiltration membranes (NF) membranes containing trimethylammonium phosphate) in nonhumidified high temperature H2-Cl2 fuel cells, as shown in Fig. 2. The non-conducting polymers provide the NSTI-Nanotech 2014, www.nsti.org, ISBN 978-1-4822-5830-1 Vol. 3, 2014 447PDF Image | Seawater Flow Battery as Technology Platform

PDF Search Title:

Seawater Flow Battery as Technology PlatformOriginal File Name Searched:

Schubert2014Seawater.pdfDIY PDF Search: Google It | Yahoo | Bing

Product and Development Focus for Salgenx

Redox Flow Battery Technology: With the advent of the new USA tax credits for producing and selling batteries ($35/kW) we are focussing on a simple flow battery using shipping containers as the modular electrolyte storage units with tax credits up to $140,000 per system. Our main focus is on the salt battery. This battery can be used for both thermal and electrical storage applications. We call it the Cogeneration Battery or Cogen Battery. One project is converting salt (brine) based water conditioners to simultaneously produce power. In addition, there are many opportunities to extract Lithium from brine (salt lakes, groundwater, and producer water).Salt water or brine are huge sources for lithium. Most of the worlds lithium is acquired from a brine source. It's even in seawater in a low concentration. Brine is also a byproduct of huge powerplants, which can now use that as an electrolyte and a huge flow battery (which allows storage at the source).We welcome any business and equipment inquiries, as well as licensing our flow battery manufacturing.| CONTACT TEL: 608-238-6001 Email: greg@salgenx.com | RSS | AMP |