PDF Publication Title:

Text from PDF Page: 006

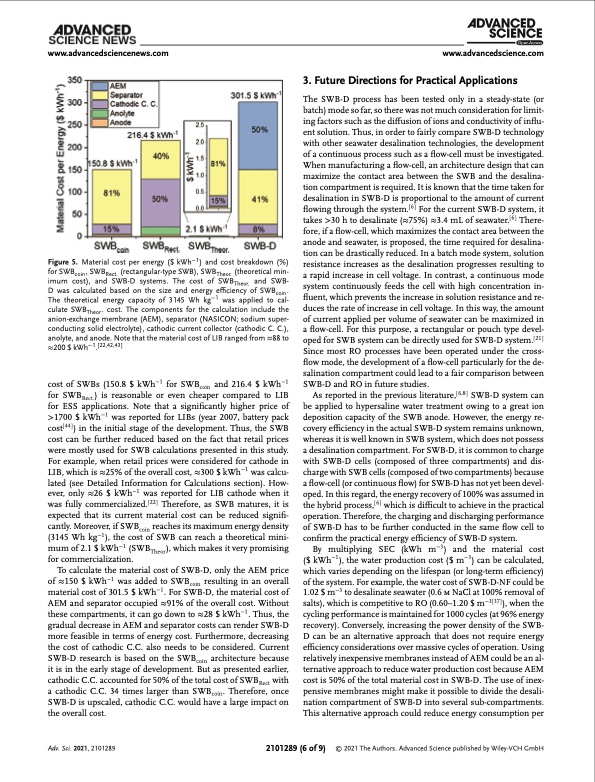

www.advancedsciencenews.com Figure 5. Material cost per energy ($ kWh−1) and cost breakdown (%) for SWBcoin, SWBRect. (rectangular-type SWB), SWBTheor. (theoretical min- imum cost), and SWB-D systems. The cost of SWBTheor. and SWB- D was calculated based on the size and energy efficiency of SWBcoin. The theoretical energy capacity of 3145 Wh kg−1 was applied to cal- culate SWBTheor. cost. The components for the calculation include the anion-exchange membrane (AEM), separator (NASICON; sodium super- conducting solid electrolyte), cathodic current collector (cathodic C. C.), anolyte, and anode. Note that the material cost of LIB ranged from ≈88 to ≈200 $ kWh−1.[22,42,43] cost of SWBs (150.8 $ kWh−1 for SWBcoin and 216.4 $ kWh−1 for SWBRect.) is reasonable or even cheaper compared to LIB for ESS applications. Note that a significantly higher price of >1700 $ kWh−1 was reported for LIBs (year 2007, battery pack cost[ 44 ] ) in the initial stage of the development. Thus, the SWB cost can be further reduced based on the fact that retail prices were mostly used for SWB calculations presented in this study. For example, when retail prices were considered for cathode in LIB, which is ≈25% of the overall cost, ≈300 $ kWh−1 was calcu- lated (see Detailed Information for Calculations section). How- ever, only ≈26 $ kWh−1 was reported for LIB cathode when it was fully commercialized.[ 22 ] Therefore, as SWB matures, it is expected that its current material cost can be reduced signifi- cantly. Moreover, if SWBcoin reaches its maximum energy density (3145 Wh kg−1), the cost of SWB can reach a theoretical mini- mum of 2.1 $ kWh−1 (SWBTheor), which makes it very promising for commercialization. To calculate the material cost of SWB-D, only the AEM price of ≈150 $ kWh−1 was added to SWBcoin resulting in an overall material cost of 301.5 $ kWh−1. For SWB-D, the material cost of AEM and separator occupied ≈91% of the overall cost. Without these compartments, it can go down to ≈28 $ kWh−1. Thus, the gradual decrease in AEM and separator costs can render SWB-D more feasible in terms of energy cost. Furthermore, decreasing the cost of cathodic C.C. also needs to be considered. Current SWB-D research is based on the SWBcoin architecture because it is in the early stage of development. But as presented earlier, cathodic C.C. accounted for 50% of the total cost of SWBRect with a cathodic C.C. 34 times larger than SWBcoin. Therefore, once SWB-D is upscaled, cathodic C.C. would have a large impact on the overall cost. www.advancedscience.com 3. Future Directions for Practical Applications The SWB-D process has been tested only in a steady-state (or batch) mode so far, so there was not much consideration for limit- ing factors such as the diffusion of ions and conductivity of influ- ent solution. Thus, in order to fairly compare SWB-D technology with other seawater desalination technologies, the development of a continuous process such as a flow-cell must be investigated. When manufacturing a flow-cell, an architecture design that can maximize the contact area between the SWB and the desalina- tion compartment is required. It is known that the time taken for desalination in SWB-D is proportional to the amount of current flowing through the system.[6] For the current SWB-D system, it takes >30 h to desalinate (≈75%) ≈3.4 mL of seawater.[6] There- fore, if a flow-cell, which maximizes the contact area between the anode and seawater, is proposed, the time required for desalina- tion can be drastically reduced. In a batch mode system, solution resistance increases as the desalination progresses resulting to a rapid increase in cell voltage. In contrast, a continuous mode system continuously feeds the cell with high concentration in- fluent, which prevents the increase in solution resistance and re- duces the rate of increase in cell voltage. In this way, the amount of current applied per volume of seawater can be maximized in a flow-cell. For this purpose, a rectangular or pouch type devel- oped for SWB system can be directly used for SWB-D system.[ 21 ] Since most RO processes have been operated under the cross- flow mode, the development of a flow-cell particularly for the de- salination compartment could lead to a fair comparison between SWB-D and RO in future studies. As reported in the previous literature,[6,8] SWB-D system can be applied to hypersaline water treatment owing to a great ion deposition capacity of the SWB anode. However, the energy re- covery efficiency in the actual SWB-D system remains unknown, whereas it is well known in SWB system, which does not possess a desalination compartment. For SWB-D, it is common to charge with SWB-D cells (composed of three compartments) and dis- charge with SWB cells (composed of two compartments) because a flow-cell (or continuous flow) for SWB-D has not yet been devel- oped. In this regard, the energy recovery of 100% was assumed in the hybrid process,[ 6 ] which is difficult to achieve in the practical operation. Therefore, the charging and discharging performance of SWB-D has to be further conducted in the same flow cell to confirm the practical energy efficiency of SWB-D system. By multiplying SEC (kWh m−3) and the material cost ($ kWh−1 ), the water production cost ($ m−3 ) can be calculated, which varies depending on the lifespan (or long-term efficiency) of the system. For example, the water cost of SWB-D-NF could be 1.02 $ m−3 to desalinate seawater (0.6 m NaCl at 100% removal of salts), which is competitive to RO (0.60–1.20 $ m−3[ 37 ] ), when the cycling performance is maintained for 1000 cycles (at 96% energy recovery). Conversely, increasing the power density of the SWB- D can be an alternative approach that does not require energy efficiency considerations over massive cycles of operation. Using relatively inexpensive membranes instead of AEM could be an al- ternative approach to reduce water production cost because AEM cost is 50% of the total material cost in SWB-D. The use of inex- pensive membranes might make it possible to divide the desali- nation compartment of SWB-D into several sub-compartments. This alternative approach could reduce energy consumption per Adv. Sci. 2021, 2101289 2101289 (6 of 9) © 2021 The Authors. Advanced Science published by Wiley-VCH GmbHPDF Image | Seawater Desalination using Rechargeable Seawater Battery

PDF Search Title:

Seawater Desalination using Rechargeable Seawater BatteryOriginal File Name Searched:

advs2827.pdfDIY PDF Search: Google It | Yahoo | Bing

Product and Development Focus for Salgenx

Redox Flow Battery Technology: With the advent of the new USA tax credits for producing and selling batteries ($35/kW) we are focussing on a simple flow battery using shipping containers as the modular electrolyte storage units with tax credits up to $140,000 per system. Our main focus is on the salt battery. This battery can be used for both thermal and electrical storage applications. We call it the Cogeneration Battery or Cogen Battery. One project is converting salt (brine) based water conditioners to simultaneously produce power. In addition, there are many opportunities to extract Lithium from brine (salt lakes, groundwater, and producer water).Salt water or brine are huge sources for lithium. Most of the worlds lithium is acquired from a brine source. It's even in seawater in a low concentration. Brine is also a byproduct of huge powerplants, which can now use that as an electrolyte and a huge flow battery (which allows storage at the source).We welcome any business and equipment inquiries, as well as licensing our flow battery manufacturing.| CONTACT TEL: 608-238-6001 Email: greg@salgenx.com | RSS | AMP |