PDF Publication Title:

Text from PDF Page: 006

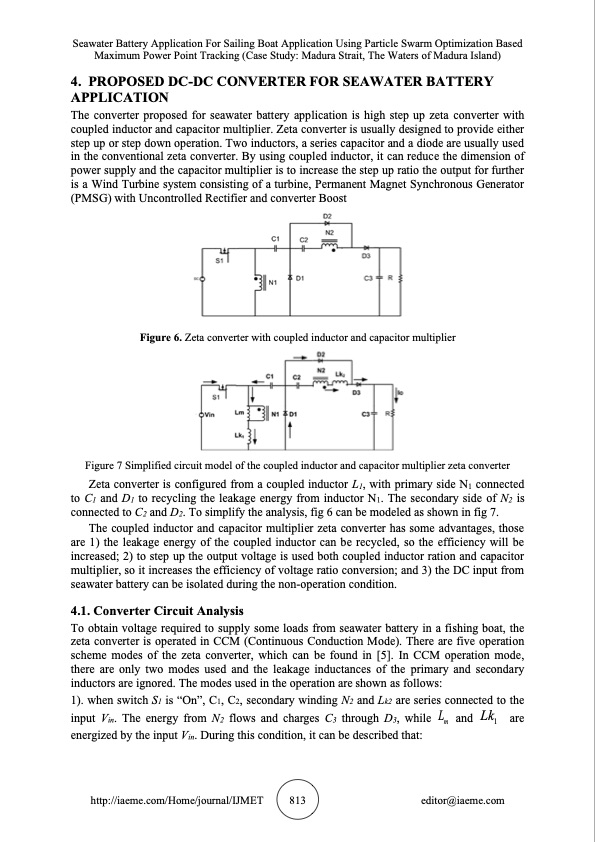

Seawater Battery Application For Sailing Boat Application Using Particle Swarm Optimization Based Maximum Power Point Tracking (Case Study: Madura Strait, The Waters of Madura Island) 4. PROPOSED DC-DC CONVERTER FOR SEAWATER BATTERY APPLICATION The converter proposed for seawater battery application is high step up zeta converter with coupled inductor and capacitor multiplier. Zeta converter is usually designed to provide either step up or step down operation. Two inductors, a series capacitor and a diode are usually used in the conventional zeta converter. By using coupled inductor, it can reduce the dimension of power supply and the capacitor multiplier is to increase the step up ratio the output for further is a Wind Turbine system consisting of a turbine, Permanent Magnet Synchronous Generator (PMSG) with Uncontrolled Rectifier and converter Boost Figure 6. Zeta converter with coupled inductor and capacitor multiplier Figure 7 Simplified circuit model of the coupled inductor and capacitor multiplier zeta converter Zeta converter is configured from a coupled inductor L1, with primary side N1 connected to C1 and D1 to recycling the leakage energy from inductor N1. The secondary side of N2 is connected to C2 and D2. To simplify the analysis, fig 6 can be modeled as shown in fig 7. The coupled inductor and capacitor multiplier zeta converter has some advantages, those are 1) the leakage energy of the coupled inductor can be recycled, so the efficiency will be increased; 2) to step up the output voltage is used both coupled inductor ration and capacitor multiplier, so it increases the efficiency of voltage ratio conversion; and 3) the DC input from seawater battery can be isolated during the non-operation condition. 4.1. Converter Circuit Analysis To obtain voltage required to supply some loads from seawater battery in a fishing boat, the zeta converter is operated in CCM (Continuous Conduction Mode). There are five operation scheme modes of the zeta converter, which can be found in [5]. In CCM operation mode, there are only two modes used and the leakage inductances of the primary and secondary inductors are ignored. The modes used in the operation are shown as follows: 1). when switch S1 is “On”, C1, C2, secondary winding N2 and Lk2 are series connected to the input Vin. The energy from N2 flows and charges C3 through D3, while Lm and Lk1 are energized by the input Vin. During this condition, it can be described that: http://iaeme.com/Home/journal/IJMET 813 editor@iaeme.comPDF Image | SEAWATER BATTERY APPLICATION FOR SAILING BOAT

PDF Search Title:

SEAWATER BATTERY APPLICATION FOR SAILING BOATOriginal File Name Searched:

IJMET_10_01_083.pdfDIY PDF Search: Google It | Yahoo | Bing

Product and Development Focus for Salgenx

Redox Flow Battery Technology: With the advent of the new USA tax credits for producing and selling batteries ($35/kW) we are focussing on a simple flow battery using shipping containers as the modular electrolyte storage units with tax credits up to $140,000 per system. Our main focus is on the salt battery. This battery can be used for both thermal and electrical storage applications. We call it the Cogeneration Battery or Cogen Battery. One project is converting salt (brine) based water conditioners to simultaneously produce power. In addition, there are many opportunities to extract Lithium from brine (salt lakes, groundwater, and producer water).Salt water or brine are huge sources for lithium. Most of the worlds lithium is acquired from a brine source. It's even in seawater in a low concentration. Brine is also a byproduct of huge powerplants, which can now use that as an electrolyte and a huge flow battery (which allows storage at the source).We welcome any business and equipment inquiries, as well as licensing our flow battery manufacturing.| CONTACT TEL: 608-238-6001 Email: greg@salgenx.com | RSS | AMP |