PDF Publication Title:

Text from PDF Page: 004

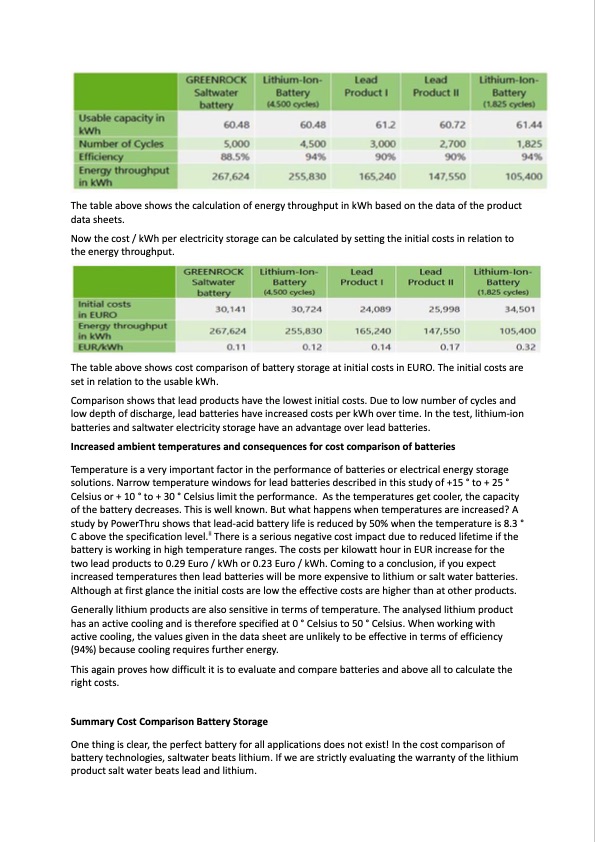

The table above shows the calculation of energy throughput in kWh based on the data of the product data sheets. Now the cost / kWh per electricity storage can be calculated by setting the initial costs in relation to the energy throughput. The table above shows cost comparison of battery storage at initial costs in EURO. The initial costs are set in relation to the usable kWh. Comparison shows that lead products have the lowest initial costs. Due to low number of cycles and low depth of discharge, lead batteries have increased costs per kWh over time. In the test, lithium-ion batteries and saltwater electricity storage have an advantage over lead batteries. Increased ambient temperatures and consequences for cost comparison of batteries Temperature is a very important factor in the performance of batteries or electrical energy storage solutions. Narrow temperature windows for lead batteries described in this study of +15 ° to + 25 ° Celsius or + 10 ° to + 30 ° Celsius limit the performance. As the temperatures get cooler, the capacity of the battery decreases. This is well known. But what happens when temperatures are increased? A study by PowerThru shows that lead-acid battery life is reduced by 50% when the temperature is 8.3 ° C above the specification level.ii There is a serious negative cost impact due to reduced lifetime if the battery is working in high temperature ranges. The costs per kilowatt hour in EUR increase for the two lead products to 0.29 Euro / kWh or 0.23 Euro / kWh. Coming to a conclusion, if you expect increased temperatures then lead batteries will be more expensive to lithium or salt water batteries. Although at first glance the initial costs are low the effective costs are higher than at other products. Generally lithium products are also sensitive in terms of temperature. The analysed lithium product has an active cooling and is therefore specified at 0 ° Celsius to 50 ° Celsius. When working with active cooling, the values given in the data sheet are unlikely to be effective in terms of efficiency (94%) because cooling requires further energy. This again proves how difficult it is to evaluate and compare batteries and above all to calculate the right costs. Summary Cost Comparison Battery Storage One thing is clear, the perfect battery for all applications does not exist! In the cost comparison of battery technologies, saltwater beats lithium. If we are strictly evaluating the warranty of the lithium product salt water beats lead and lithium.PDF Image | new generation of saltwater batteries

PDF Search Title:

new generation of saltwater batteriesOriginal File Name Searched:

Dr-Thomas-F-Krausse-BlueSky-Energy-paper.pdfDIY PDF Search: Google It | Yahoo | Bing

Product and Development Focus for Salgenx

Redox Flow Battery Technology: With the advent of the new USA tax credits for producing and selling batteries ($35/kW) we are focussing on a simple flow battery using shipping containers as the modular electrolyte storage units with tax credits up to $140,000 per system. Our main focus is on the salt battery. This battery can be used for both thermal and electrical storage applications. We call it the Cogeneration Battery or Cogen Battery. One project is converting salt (brine) based water conditioners to simultaneously produce power. In addition, there are many opportunities to extract Lithium from brine (salt lakes, groundwater, and producer water).Salt water or brine are huge sources for lithium. Most of the worlds lithium is acquired from a brine source. It's even in seawater in a low concentration. Brine is also a byproduct of huge powerplants, which can now use that as an electrolyte and a huge flow battery (which allows storage at the source).We welcome any business and equipment inquiries, as well as licensing our flow battery manufacturing.| CONTACT TEL: 608-238-6001 Email: greg@salgenx.com | RSS | AMP |