PDF Publication Title:

Text from PDF Page: 005

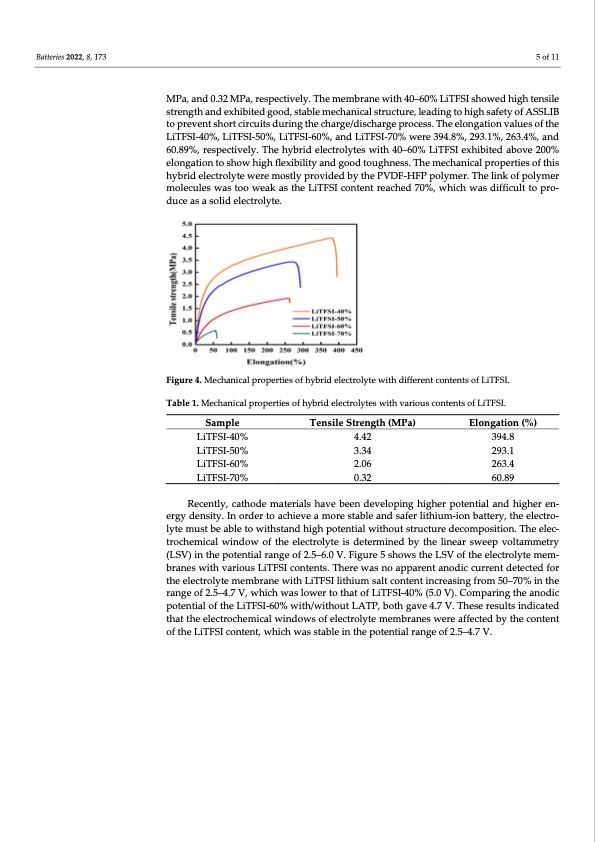

Batteries 2022, 8, 173 5 of 11 MPa, and 0.32 MPa, respectively. The membrane with 40–60% LiTFSI showed high tensile strength and exhibited good, stable mechanical structure, leading to high safety of ASSLIB to prevent short circuits during the charge/discharge process. The elongation values of the LiTFSI-40%, LiTFSI-50%, LiTFSI-60%, and LiTFSI-70% were 394.8%, 293.1%, 263.4%, and 60.89%, respectively. The hybrid electrolytes with 40–60% LiTFSI exhibited above 200% elongation to show high flexibility and good toughness. The mechanical properties of this hybrid electrolyte were mostly provided by the PVDF-HFP polymer. The link of polymer molecules was too weak as the LiTFSI content reached 70%, which was difficult to pro- duce as a solid electrolyte. Figure 4. Mechanical properties of hybrid electrolyte with different contents of LiTFSI. Table 1. Mechanical properties of hybrid electrolytes with various contents of LiTFSI. Sample LiTFSI-40% LiTFSI-50% LiTFSI-60% LiTFSI-70% Tensile Strength (MPa) 4.42 3.34 2.06 0.32 Elongation (%) 394.8 293.1 263.4 60.89 Recently, cathode materials have been developing higher potential and higher en- ergy density. In order to achieve a more stable and safer lithium-ion battery, the electro- lyte must be able to withstand high potential without structure decomposition. The elec- trochemical window of the electrolyte is determined by the linear sweep voltammetry (LSV) in the potential range of 2.5–6.0 V. Figure 5 shows the LSV of the electrolyte mem- branes with various LiTFSI contents. There was no apparent anodic current detected for the electrolyte membrane with LiTFSI lithium salt content increasing from 50–70% in the range of 2.5–4.7 V, which was lower to that of LiTFSI-40% (5.0 V). Comparing the anodic potential of the LiTFSI-60% with/without LATP, both gave 4.7 V. These results indicated that the electrochemical windows of electrolyte membranes were affected by the content of the LiTFSI content, which was stable in the potential range of 2.5–4.7 V.PDF Image | Lithium Salt Concentration on Materials

PDF Search Title:

Lithium Salt Concentration on MaterialsOriginal File Name Searched:

batteries-08-00173.pdfDIY PDF Search: Google It | Yahoo | Bing

Product and Development Focus for Salgenx

Redox Flow Battery Technology: With the advent of the new USA tax credits for producing and selling batteries ($35/kW) we are focussing on a simple flow battery using shipping containers as the modular electrolyte storage units with tax credits up to $140,000 per system. Our main focus is on the salt battery. This battery can be used for both thermal and electrical storage applications. We call it the Cogeneration Battery or Cogen Battery. One project is converting salt (brine) based water conditioners to simultaneously produce power. In addition, there are many opportunities to extract Lithium from brine (salt lakes, groundwater, and producer water).Salt water or brine are huge sources for lithium. Most of the worlds lithium is acquired from a brine source. It's even in seawater in a low concentration. Brine is also a byproduct of huge powerplants, which can now use that as an electrolyte and a huge flow battery (which allows storage at the source).We welcome any business and equipment inquiries, as well as licensing our flow battery manufacturing.| CONTACT TEL: 608-238-6001 Email: greg@salgenx.com | RSS | AMP |