PDF Publication Title:

Text from PDF Page: 021

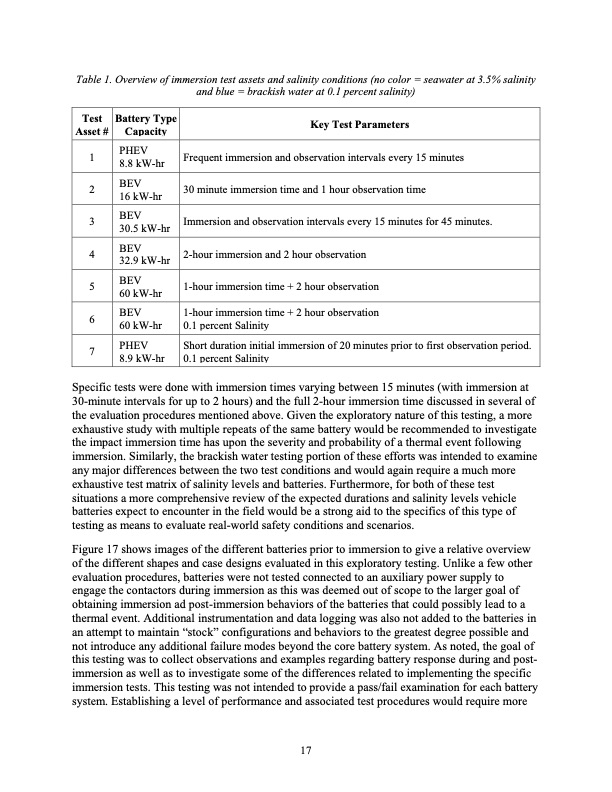

Table 1. Overview of immersion test assets and salinity conditions (no color = seawater at 3.5% salinity and blue = brackish water at 0.1 percent salinity) Test Asset # 1 2 3 4 5 6 7 Battery Type Capacity PHEV 8.8 kW-hr BEV 16 kW-hr BEV 30.5 kW-hr BEV 32.9 kW-hr BEV 60 kW-hr BEV 60 kW-hr PHEV 8.9 kW-hr Key Test Parameters Frequent immersion and observation intervals every 15 minutes 30 minute immersion time and 1 hour observation time Immersion and observation intervals every 15 minutes for 45 minutes. 2-hour immersion and 2 hour observation 1-hour immersion time + 2 hour observation 1-hour immersion time + 2 hour observation 0.1 percent Salinity Short duration initial immersion of 20 minutes prior to first observation period. 0.1 percent Salinity Specific tests were done with immersion times varying between 15 minutes (with immersion at 30-minute intervals for up to 2 hours) and the full 2-hour immersion time discussed in several of the evaluation procedures mentioned above. Given the exploratory nature of this testing, a more exhaustive study with multiple repeats of the same battery would be recommended to investigate the impact immersion time has upon the severity and probability of a thermal event following immersion. Similarly, the brackish water testing portion of these efforts was intended to examine any major differences between the two test conditions and would again require a much more exhaustive test matrix of salinity levels and batteries. Furthermore, for both of these test situations a more comprehensive review of the expected durations and salinity levels vehicle batteries expect to encounter in the field would be a strong aid to the specifics of this type of testing as means to evaluate real-world safety conditions and scenarios. Figure 17 shows images of the different batteries prior to immersion to give a relative overview of the different shapes and case designs evaluated in this exploratory testing. Unlike a few other evaluation procedures, batteries were not tested connected to an auxiliary power supply to engage the contactors during immersion as this was deemed out of scope to the larger goal of obtaining immersion ad post-immersion behaviors of the batteries that could possibly lead to a thermal event. Additional instrumentation and data logging was also not added to the batteries in an attempt to maintain “stock” configurations and behaviors to the greatest degree possible and not introduce any additional failure modes beyond the core battery system. As noted, the goal of this testing was to collect observations and examples regarding battery response during and post- immersion as well as to investigate some of the differences related to implementing the specific immersion tests. This testing was not intended to provide a pass/fail examination for each battery system. Establishing a level of performance and associated test procedures would require more 17PDF Image | Li-Ion Battery Pack Immersion Exploratory Investigation

PDF Search Title:

Li-Ion Battery Pack Immersion Exploratory InvestigationOriginal File Name Searched:

dot_57013_DS1.pdfDIY PDF Search: Google It | Yahoo | Bing

Product and Development Focus for Salgenx

Redox Flow Battery Technology: With the advent of the new USA tax credits for producing and selling batteries ($35/kW) we are focussing on a simple flow battery using shipping containers as the modular electrolyte storage units with tax credits up to $140,000 per system. Our main focus is on the salt battery. This battery can be used for both thermal and electrical storage applications. We call it the Cogeneration Battery or Cogen Battery. One project is converting salt (brine) based water conditioners to simultaneously produce power. In addition, there are many opportunities to extract Lithium from brine (salt lakes, groundwater, and producer water).Salt water or brine are huge sources for lithium. Most of the worlds lithium is acquired from a brine source. It's even in seawater in a low concentration. Brine is also a byproduct of huge powerplants, which can now use that as an electrolyte and a huge flow battery (which allows storage at the source).We welcome any business and equipment inquiries, as well as licensing our flow battery manufacturing.| CONTACT TEL: 608-238-6001 Email: greg@salgenx.com | RSS | AMP |