PDF Publication Title:

Text from PDF Page: 004

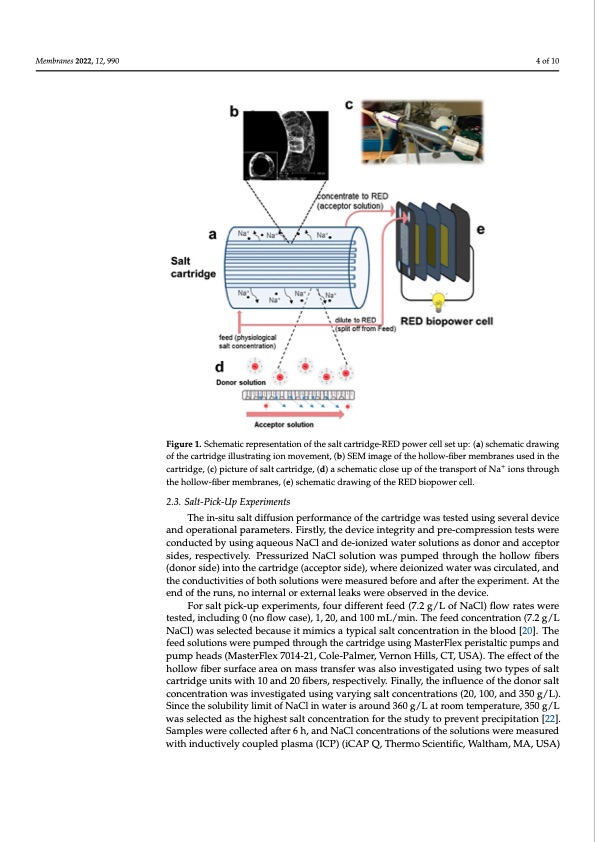

Membranes 2022, 12, x FOR PEER REVIEW 4 of 10 Membranes 2022, 12, 990 4 of 10 Figure 1. Schematic representation of the salt cartridge-RED power cell set up: (a) schematic drawing Figure 1. Schematic representation of the salt cartridge-RED power cell set up: (a) schematic draw- ionfgthofetchaertcraidrtgreidilgluesitlrluatsitnrgationngmioonvmemovenemt, (ebn)t,S(EbM) SiEmMagiemoafgteheofhtohlleohwo-lfilobwer-fmibeemrbmraenmebsruasneedsiunstehde ++ icnarthtreidcgaer,tr(icd)gpei,ct(uc)repoicftusarletocafrstarildtgcaer,t(rdid)gaes,c(hde)maasticchcelmosaetiucpclofsethueptroanfsthpeorttraonfsNpaortionfsNtharoioungsh through the hollow-fiber membranes, (e) schematic drawing of the RED biopower cell. the hollow-fiber membranes, (e) schematic drawing of the RED biopower cell. 2.3. Salt-Pick-Up Experiments 2.3. Salt-Pick-Up Experiments The in-situ salt diffusion performance of the cartridge was tested using several device The in-situ salt diffusion performance of the cartridge was tested using several device and operational parameters. Firstly, the device integrity and pre-compression tests were and operational parameters. Firstly, the device integrity and pre-compression tests were conducted by using aqueous NaCl and de-ionized water solutions as donor and acceptor conducted by using aqueous NaCl and de-ionized water solutions as donor and acceptor sides, respectively. Pressurized NaCl solution was pumped through the hollow fibers sides, respectively. Pressurized NaCl solution was pumped through the hollow fibers (do- (donor side) into the cartridge (acceptor side), where deionized water was circulated, and nor side) into the cartridge (acceptor side), where deionized water was circulated, and the the conductivities of both solutions were measured before and after the experiment. At the conductivities of both solutions were measured before and after the experiment. At the end of the runs, no internal or external leaks were observed in the device. end of the runs, no internal or external leaks were observed in the device. For salt pick-up experiments, four different feed (7.2 g/L of NaCl) flow rates were For salt pick-up experiments, four different feed (7.2 g/L of NaCl) flow rates were tested, including 0 (no flow case), 1, 20, and 100 mL/min. The feed concentration (7.2 g/L tested, including 0 (no flow case), 1, 20, and 100 mL/min. The feed concentration (7.2 g/L NaCl) was selected because it mimics a typical salt concentration in the blood [20]. The NaCl) was selected because it mimics a typical salt concentration in the blood [20]. The feed solutions were pumped through the cartridge using MasterFlex peristaltic pumps and feed solutions were pumped through the cartridge using MasterFlex peristaltic pumps pump heads (MasterFlex 7014-21, Cole-Palmer, Vernon Hills, CT, USA). The effect of the and pump heads (MasterFlex 7014-21, Cole-Palmer, Vernon Hills, CT, USA). The effect of hollow fiber surface area on mass transfer was also investigated using two types of salt the hollow fiber surface area on mass transfer was also investigated using two types of cartridge units with 10 and 20 fibers, respectively. Finally, the influence of the donor salt salt cartridge units with 10 and 20 fibers, respectively. Finally, the influence of the donor concentration was investigated using varying salt concentrations (20, 100, and 350 g/L). salt concentration was investigated using varying salt concentrations (20, 100, and 350 Since the solubility limit of NaCl in water is around 360 g/L at room temperature, 350 g/L g/L). Since the solubility limit of NaCl in water is around 360 g/L at room temperature, was selected as the highest salt concentration for the study to prevent precipitation [22]. 350 g/L was selected as the highest salt concentration for the study to prevent precipitation Samples were collected after 6 h, and NaCl concentrations of the solutions were measured [22]. Samples were collected after 6 h, and NaCl concentrations of the solutions were with inductively coupled plasma (ICP) (iCAP Q, Thermo Scientific, Waltham, MA, USA) measured with inductively coupled plasma (ICP) (iCAP Q, Thermo Scientific, Waltham, MA, USA) and conductivity measurements (Fisherbrand, Thermo Scientific, Waltham,PDF Image | Integrated Salt Cartridge-Reverse Electrodialysis

PDF Search Title:

Integrated Salt Cartridge-Reverse ElectrodialysisOriginal File Name Searched:

membranes-12-00990.pdfDIY PDF Search: Google It | Yahoo | Bing

Product and Development Focus for Salgenx

Redox Flow Battery Technology: With the advent of the new USA tax credits for producing and selling batteries ($35/kW) we are focussing on a simple flow battery using shipping containers as the modular electrolyte storage units with tax credits up to $140,000 per system. Our main focus is on the salt battery. This battery can be used for both thermal and electrical storage applications. We call it the Cogeneration Battery or Cogen Battery. One project is converting salt (brine) based water conditioners to simultaneously produce power. In addition, there are many opportunities to extract Lithium from brine (salt lakes, groundwater, and producer water).Salt water or brine are huge sources for lithium. Most of the worlds lithium is acquired from a brine source. It's even in seawater in a low concentration. Brine is also a byproduct of huge powerplants, which can now use that as an electrolyte and a huge flow battery (which allows storage at the source).We welcome any business and equipment inquiries, as well as licensing our flow battery manufacturing.| CONTACT TEL: 608-238-6001 Email: greg@salgenx.com | RSS | AMP |