PDF Publication Title:

Text from PDF Page: 018

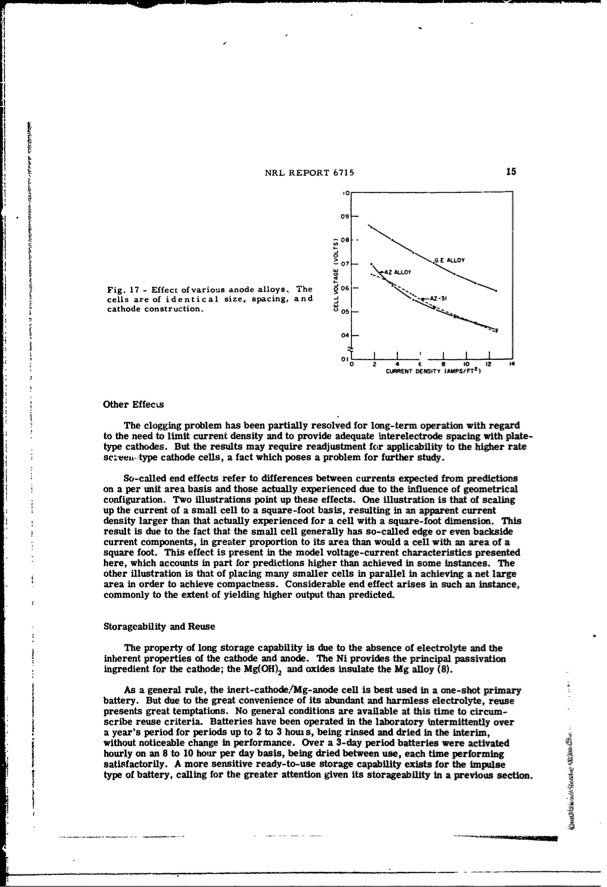

Fig. 17- Effect of various anode alloys., The -06- 0jI -07 06-. N.ý-.G E ALLOY 0Y -Z- oI, I ' I I, I cells are of identical cathode construction. Other Effects size, spacing, and J 005 04 NRL REPORT 6715 15 The clogging problem has been partially resolved for long-term operation with regard to the need to limit current density and to provide adequate interelectrode spacing with plate- type cathodes. But the results may require readjustment for applicability to the higher rate scC'eew type cathode cells, a fact which poses a problem for further study. So-called end effects refer to differences between currents expected from predictions on a per unit area basis and those actually experienced due to the influence of geometrical configuration. Two illustrations point up these effects. One illustration is that of scaling up the current of a small cell to a square-foot basis, resulting in an apparent current density larger than that actually experienced for a cell with a square-foot dimension. This result is due to the fact that the small cell generally has so-called edge or even backside current components, in greater proportion to its area than would a cell with an area of a square foot. This effect is present in the model voltage-current characteristics presented here, which accounts in part for predictions higher than achieved in some instances. The other illustration is that of placing many smaller cells in parallel in achieving a net large area in order to achieve compactness. Considerable end effect arises in such an instance, commonly to the extent of yielding higher output than predicted. Storageability and Reuse The property of long storage capability is due to the absence of electrolyte and the inherent properties of the cathode and anode. The Ni provides the principal passivation ingredient for the cathode; the Mg(OH)2 and oxides insulate the Mg alloy (8). As a general rule, the inert-cathode/Mg-anode cell is best used in a one-shot primary battery. But due to the great convenience of its abundant and harmless electrolyte, reuse presents great temptations. No general conditions are available at this time to circum- scribe reuse criteria. Batteries have been operated in the laboratory intermittently over a year's period for periods up to 2 to 3 horu s, being rinsed and dried in the interim, without noticeable change in performance. Over a 3-day period batteries were activated hourly on an 8 to 10 hour per day basis, being dried between use, each time performing . satisfactorily. A more sensitive ready-to-use storage capability exists for the impulse type of battery, calling for the greater attention given its storageability in a previous section. 10~~ 09 0 2 4 E a 10 12 14 2 CURRENT DENSITY (AMPS/FT )PDF Image | INERT-CATHODE SEA-WATER BATTERY

PDF Search Title:

INERT-CATHODE SEA-WATER BATTERYOriginal File Name Searched:

AD0673399.pdfDIY PDF Search: Google It | Yahoo | Bing

Product and Development Focus for Salgenx

Redox Flow Battery Technology: With the advent of the new USA tax credits for producing and selling batteries ($35/kW) we are focussing on a simple flow battery using shipping containers as the modular electrolyte storage units with tax credits up to $140,000 per system. Our main focus is on the salt battery. This battery can be used for both thermal and electrical storage applications. We call it the Cogeneration Battery or Cogen Battery. One project is converting salt (brine) based water conditioners to simultaneously produce power. In addition, there are many opportunities to extract Lithium from brine (salt lakes, groundwater, and producer water).Salt water or brine are huge sources for lithium. Most of the worlds lithium is acquired from a brine source. It's even in seawater in a low concentration. Brine is also a byproduct of huge powerplants, which can now use that as an electrolyte and a huge flow battery (which allows storage at the source).We welcome any business and equipment inquiries, as well as licensing our flow battery manufacturing.| CONTACT TEL: 608-238-6001 Email: greg@salgenx.com | RSS | AMP |