PDF Publication Title:

Text from PDF Page: 016

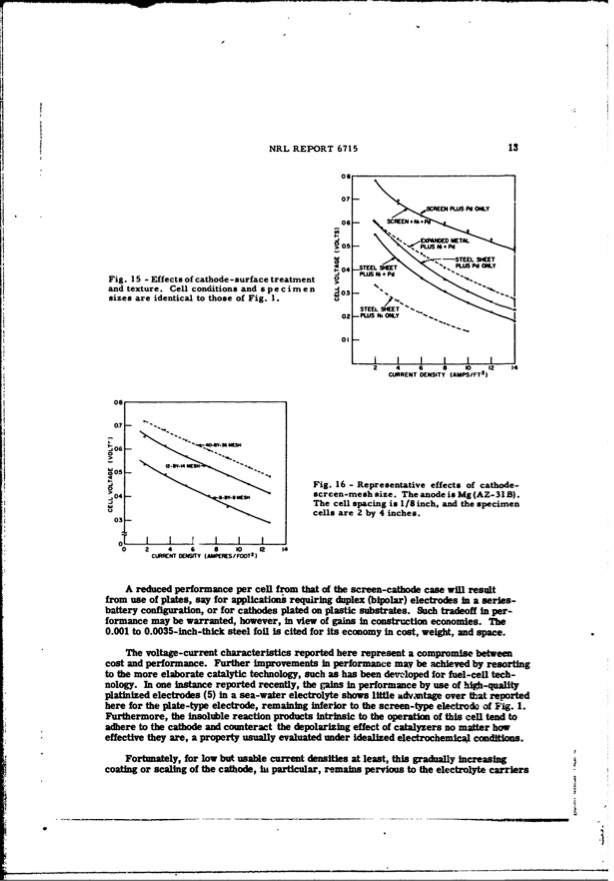

I LI NRL REPORT 6715 07 Fig. 15 - Effects of cathode-surface treatment o 13 and texture. Cell conditions and s p ecim e n sizes are identical to those of Fig. 1. 08 0.7 --" Io- 0 W05 - -0 o04 03 o-"s'r 05.U -P-MU PPdLS M •," " ... 0 2 4 6 6 to 12 14 2 CUWRCNTDENSITY(*MPVS/FOOT ) S~cells Fig. 16 - Representative effects of cathode- screen-mesh size The anode is Mg (AZ-31B). The cell spacing is 1/8 inch, and the specimen are 2 by 4 inches. -J A reduced performance per cell from that of the screen-cathode case will result from use of plates, say for applicationi requiring duplex (bipolar) electrodes in a series- battery configuration, or for cathodes plated on plastic substrates. Such tradeoff in per- formance may be warranted, however, in view of gains in construction economies. The 0.001 to 0.0035-inch-thick steel foil is cited for its economy in cost, weight, and space. The voltage-current characteristics reported here represent a compromise between cost and performance. Further improvements in performance may be achieved by resorting to the more elaborate catalytic technology, such as has been developed for fuel-cell tech- nology. In one instance reported recently, the gains in performance by use of high-quality platinized electrodes (5) in a sea-water electrolyte shows little advantage over that reported here for the plate-type electrode, remaining inferior to the screen-type electrode of Fig. 1. Furthermore, the insoluble reaction products intrinsic to the operation of this cell tend to adhere to the cathode and counteract the depolarizing effect of catalyzers no matter how effective they are, a property usually evaluated under idealized electrochemical conditions. Fortunately, for low but usable current densities at least, this gradually increasing coating or scaling of the cathode, hi particular, remains pervious to the electrolyte carriers 9•' 0 J0-3 . No OWLY 02 . 2 4 6 S t0 12 14 2 CURRENT DENSITY (AMPS/FT )PDF Image | INERT-CATHODE SEA-WATER BATTERY

PDF Search Title:

INERT-CATHODE SEA-WATER BATTERYOriginal File Name Searched:

AD0673399.pdfDIY PDF Search: Google It | Yahoo | Bing

Product and Development Focus for Salgenx

Redox Flow Battery Technology: With the advent of the new USA tax credits for producing and selling batteries ($35/kW) we are focussing on a simple flow battery using shipping containers as the modular electrolyte storage units with tax credits up to $140,000 per system. Our main focus is on the salt battery. This battery can be used for both thermal and electrical storage applications. We call it the Cogeneration Battery or Cogen Battery. One project is converting salt (brine) based water conditioners to simultaneously produce power. In addition, there are many opportunities to extract Lithium from brine (salt lakes, groundwater, and producer water).Salt water or brine are huge sources for lithium. Most of the worlds lithium is acquired from a brine source. It's even in seawater in a low concentration. Brine is also a byproduct of huge powerplants, which can now use that as an electrolyte and a huge flow battery (which allows storage at the source).We welcome any business and equipment inquiries, as well as licensing our flow battery manufacturing.| CONTACT TEL: 608-238-6001 Email: greg@salgenx.com | RSS | AMP |