PDF Publication Title:

Text from PDF Page: 015

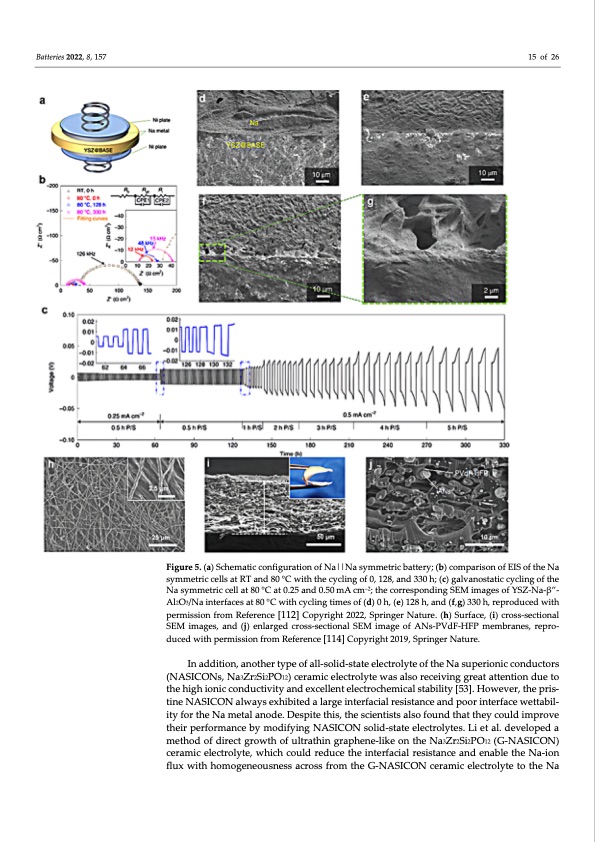

Batteries 2022, 8, 157 15 of 26 Figure 5. (a) Schematic configuration of Na||Na symmetric battery; (b) comparison of EIS of the Na symmetric cells at RT and 80 °C with the cycling of 0, 128, and 330 h; (c) galvanostatic cycling of the Na symmetric cell at 80 °C at 0.25 and 0.50 mA cm–2; the corresponding SEM images of YSZ‐Na‐β”‐ Al2O3/Na interfaces at 80 °C with cycling times of (d) 0 h, (e) 128 h, and (f,g) 330 h, reproduced with permission from Reference [112] Copyright 2022, Springer Nature. (h) Surface, (i) cross‐sectional SEM images, and (j) enlarged cross‐sectional SEM image of ANs‐PVdF‐HFP membranes, repro‐ duced with permission from Reference [114] Copyright 2019, Springer Nature. In addition, another type of all‐solid‐state electrolyte of the Na superionic conductors (NASICONs, Na3Zr2Si2PO12) ceramic electrolyte was also receiving great attention due to the high ionic conductivity and excellent electrochemical stability [53]. However, the pris‐ tine NASICON always exhibited a large interfacial resistance and poor interface wettabil‐ ity for the Na metal anode. Despite this, the scientists also found that they could improve their performance by modifying NASICON solid‐state electrolytes. Li et al. developed a method of direct growth of ultrathin graphene‐like on the Na3Zr2Si2PO12 (G‐NASICON) ceramic electrolyte, which could reduce the interfacial resistance and enable the Na‐ion flux with homogeneousness across from the G‐NASICON ceramic electrolyte to the NaPDF Image | Electrolyte Engineering for Sodium Metal Batteries

PDF Search Title:

Electrolyte Engineering for Sodium Metal BatteriesOriginal File Name Searched:

batteries-08-00157.pdfDIY PDF Search: Google It | Yahoo | Bing

Product and Development Focus for Salgenx

Redox Flow Battery Technology: With the advent of the new USA tax credits for producing and selling batteries ($35/kW) we are focussing on a simple flow battery using shipping containers as the modular electrolyte storage units with tax credits up to $140,000 per system. Our main focus is on the salt battery. This battery can be used for both thermal and electrical storage applications. We call it the Cogeneration Battery or Cogen Battery. One project is converting salt (brine) based water conditioners to simultaneously produce power. In addition, there are many opportunities to extract Lithium from brine (salt lakes, groundwater, and producer water).Salt water or brine are huge sources for lithium. Most of the worlds lithium is acquired from a brine source. It's even in seawater in a low concentration. Brine is also a byproduct of huge powerplants, which can now use that as an electrolyte and a huge flow battery (which allows storage at the source).We welcome any business and equipment inquiries, as well as licensing our flow battery manufacturing.| CONTACT TEL: 608-238-6001 Email: greg@salgenx.com | RSS | AMP |