PDF Publication Title:

Text from PDF Page: 004

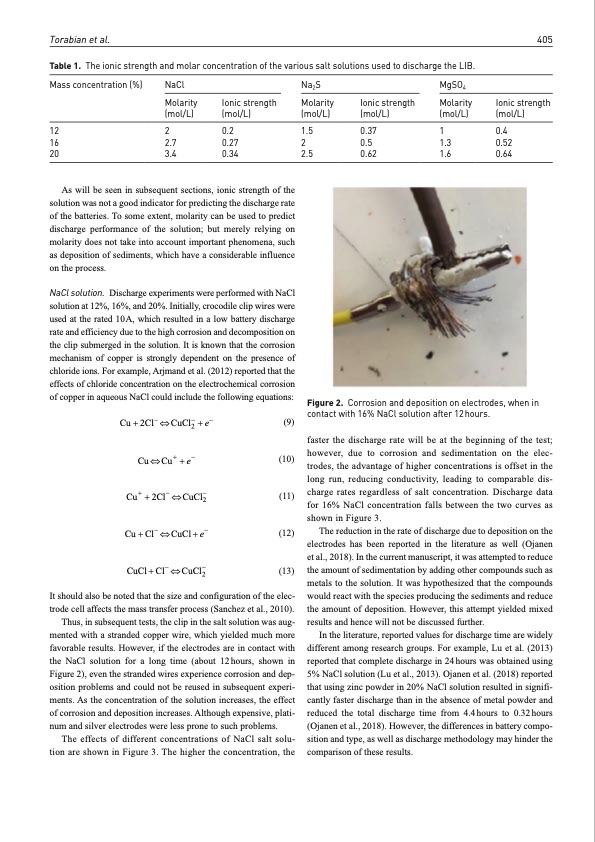

Torabian et al. 405 Table 1. The ionic strength and molar concentration of the various salt solutions used to discharge the LIB. Mass concentration (%) 12 16 20 NaCl Molarity Ionic strength (mol/L) (mol/L) 2 0.2 2.7 0.27 3.4 0.34 Na2S MgSO4 Molarity Ionic strength (mol/L) (mol/L) 1.5 0.37 2 0.5 2.5 0.62 Molarity Ionic strength (mol/L) (mol/L) 1 0.4 1.3 0.52 1.6 0.64 As will be seen in subsequent sections, ionic strength of the solution was not a good indicator for predicting the discharge rate of the batteries. To some extent, molarity can be used to predict discharge performance of the solution; but merely relying on molarity does not take into account important phenomena, such as deposition of sediments, which have a considerable influence on the process. NaClsolution. DischargeexperimentswereperformedwithNaCl solution at 12%, 16%, and 20%. Initially, crocodile clip wires were used at the rated 10A, which resulted in a low battery discharge rate and efficiency due to the high corrosion and decomposition on the clip submerged in the solution. It is known that the corrosion mechanism of copper is strongly dependent on the presence of chloride ions. For example, Arjmand et al. (2012) reported that the effects of chloride concentration on the electrochemical corrosion of copper in aqueous NaCl could include the following equations: Figure 2. Corrosion and deposition on electrodes, when in contact with 16% NaCl solution after 12 hours. (9) (10) Cu++2Cl−⇔CuCl− (11) Cu + Cl− ⇔ CuCl + e− (12) CuCl+Cl−⇔CuCl−2 (13) It should also be noted that the size and configuration of the elec- trode cell affects the mass transfer process (Sanchez et al., 2010). Thus, in subsequent tests, the clip in the salt solution was aug- mented with a stranded copper wire, which yielded much more favorable results. However, if the electrodes are in contact with the NaCl solution for a long time (about 12hours, shown in Figure 2), even the stranded wires experience corrosion and dep- osition problems and could not be reused in subsequent experi- ments. As the concentration of the solution increases, the effect of corrosion and deposition increases. Although expensive, plati- num and silver electrodes were less prone to such problems. The effects of different concentrations of NaCl salt solu- tion are shown in Figure 3. The higher the concentration, the Cu + 2Cl− ⇔CuCl− + e− 2 Cu⇔Cu+ +e− faster the discharge rate will be at the beginning of the test; however, due to corrosion and sedimentation on the elec- trodes, the advantage of higher concentrations is offset in the long run, reducing conductivity, leading to comparable dis- charge rates regardless of salt concentration. Discharge data for 16% NaCl concentration falls between the two curves as shown in Figure 3. The reduction in the rate of discharge due to deposition on the electrodes has been reported in the literature as well (Ojanen et al., 2018). In the current manuscript, it was attempted to reduce the amount of sedimentation by adding other compounds such as metals to the solution. It was hypothesized that the compounds would react with the species producing the sediments and reduce the amount of deposition. However, this attempt yielded mixed results and hence will not be discussed further. In the literature, reported values for discharge time are widely different among research groups. For example, Lu et al. (2013) reported that complete discharge in 24 hours was obtained using 5% NaCl solution (Lu et al., 2013). Ojanen et al. (2018) reported that using zinc powder in 20% NaCl solution resulted in signifi- cantly faster discharge than in the absence of metal powder and reduced the total discharge time from 4.4hours to 0.32hours (Ojanen et al., 2018). However, the differences in battery compo- sition and type, as well as discharge methodology may hinder the comparison of these results. 2PDF Image | Discharge of lithium-ion batteries in salt solutions

PDF Search Title:

Discharge of lithium-ion batteries in salt solutionsOriginal File Name Searched:

0734242x211022658.pdfDIY PDF Search: Google It | Yahoo | Bing

Product and Development Focus for Salgenx

Redox Flow Battery Technology: With the advent of the new USA tax credits for producing and selling batteries ($35/kW) we are focussing on a simple flow battery using shipping containers as the modular electrolyte storage units with tax credits up to $140,000 per system. Our main focus is on the salt battery. This battery can be used for both thermal and electrical storage applications. We call it the Cogeneration Battery or Cogen Battery. One project is converting salt (brine) based water conditioners to simultaneously produce power. In addition, there are many opportunities to extract Lithium from brine (salt lakes, groundwater, and producer water).Salt water or brine are huge sources for lithium. Most of the worlds lithium is acquired from a brine source. It's even in seawater in a low concentration. Brine is also a byproduct of huge powerplants, which can now use that as an electrolyte and a huge flow battery (which allows storage at the source).We welcome any business and equipment inquiries, as well as licensing our flow battery manufacturing.| CONTACT TEL: 608-238-6001 Email: greg@salgenx.com | RSS | AMP |