Search Completed | Title | Safety of Grid Scale Lithium-ion Battery Energy Storage Systems

Original File Name Searched: EN010106-004026-DL2-Li-ion-BESS-safety-concerns_Redacted.pdf | Google It | Yahoo | Bing

Page | 013 – 12 – June 5, 2021

A report by Underwriters Laboratories (UL) on the same incident [9] is less technical on the physics and engineering of the underlying causes and failure modes, but more comprehensive in terms of practical situations and consequences found, and suffered, by the “first-responders”. Two fire-fighters suffered life-limiting brain injuries, one suffered spinal damage and fourth facial lacerations. This report is similarly essential reading for any fire and emergency response planning.

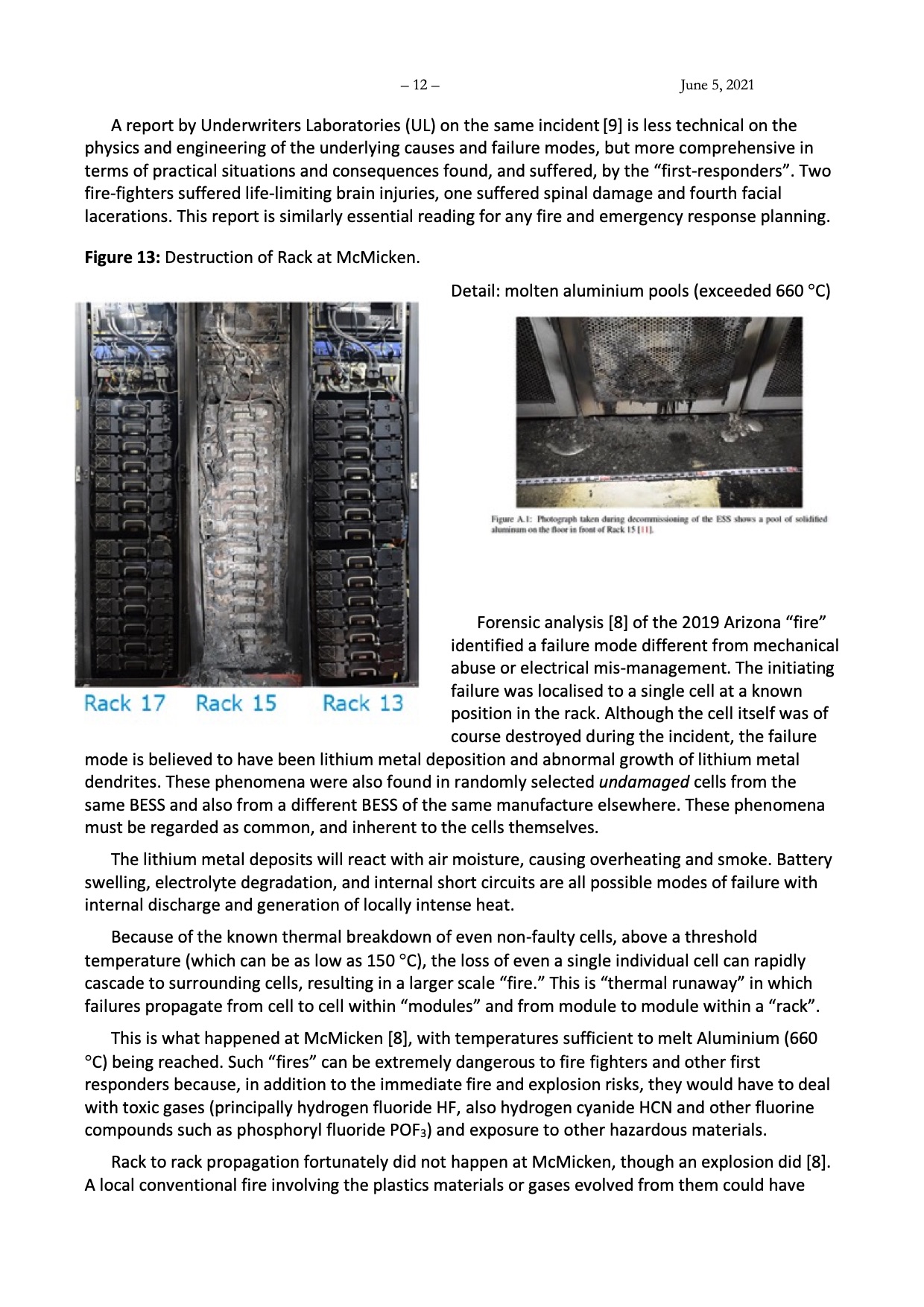

Figure 13: Destruction of Rack at McMicken.

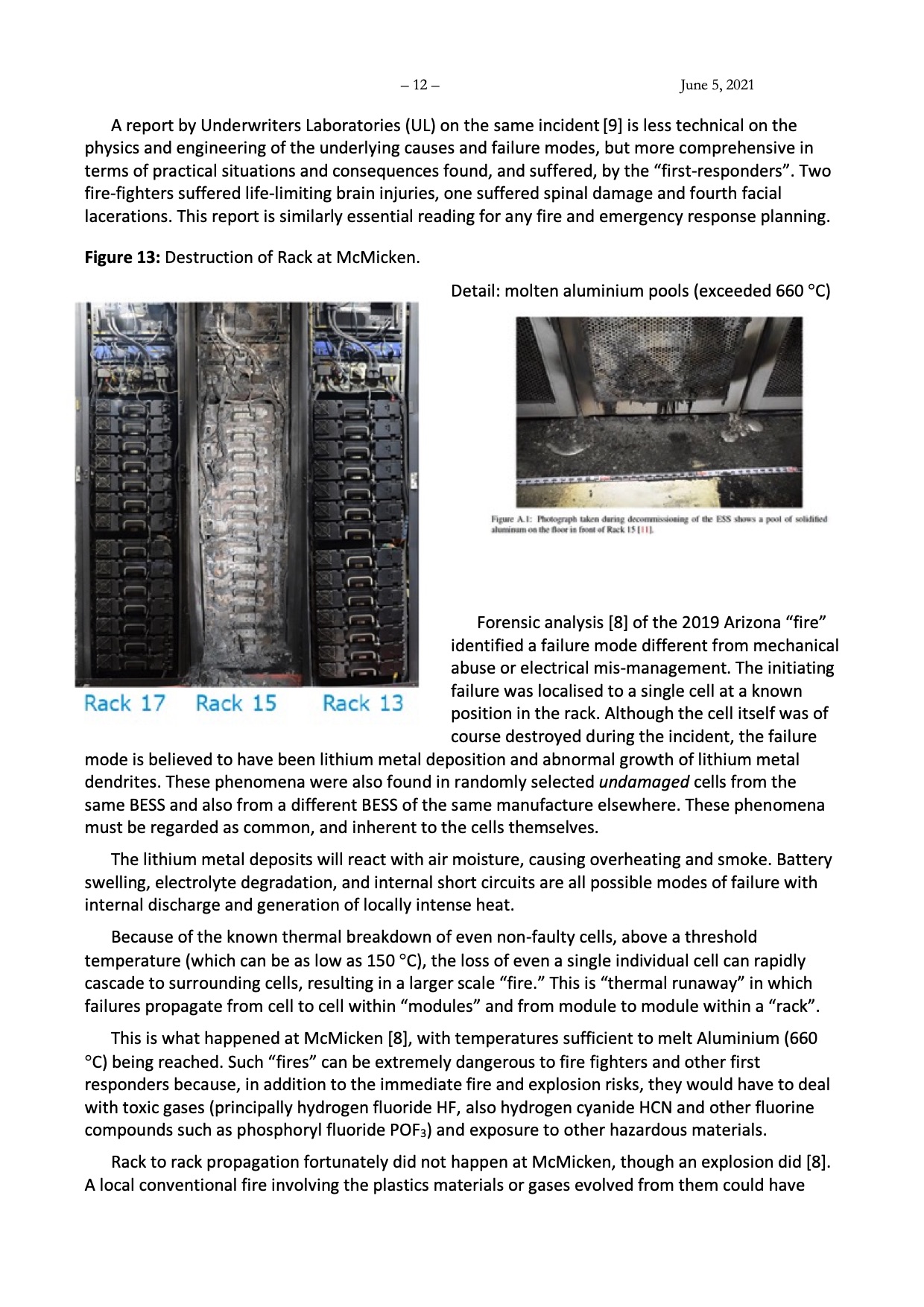

Detail: molten aluminium pools (exceeded 660 °C)

Forensic analysis [8] of the 2019 Arizona “fire” identified a failure mode different from mechanical abuse or electrical mis-management. The initiating failure was localised to a single cell at a known position in the rack. Although the cell itself was of course destroyed during the incident, the failure

mode is believed to have been lithium metal deposition and abnormal growth of lithium metal dendrites. These phenomena were also found in randomly selected undamaged cells from the same BESS and also from a different BESS of the same manufacture elsewhere. These phenomena must be regarded as common, and inherent to the cells themselves.

The lithium metal deposits will react with air moisture, causing overheating and smoke. Battery swelling, electrolyte degradation, and internal short circuits are all possible modes of failure with internal discharge and generation of locally intense heat.

Because of the known thermal breakdown of even non-faulty cells, above a threshold temperature (which can be as low as 150 °C), the loss of even a single individual cell can rapidly cascade to surrounding cells, resulting in a larger scale “fire.” This is “thermal runaway” in which failures propagate from cell to cell within “modules” and from module to module within a “rack”.

This is what happened at McMicken [8], with temperatures sufficient to melt Aluminium (660 °C) being reached. Such “fires” can be extremely dangerous to fire fighters and other first responders because, in addition to the immediate fire and explosion risks, they would have to deal with toxic gases (principally hydrogen fluoride HF, also hydrogen cyanide HCN and other fluorine compounds such as phosphoryl fluoride POF3) and exposure to other hazardous materials.

Rack to rack propagation fortunately did not happen at McMicken, though an explosion did [8]. A local conventional fire involving the plastics materials or gases evolved from them could have

|